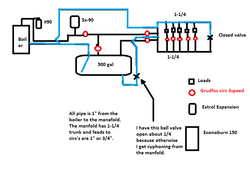

Guys, I am still having this problem with my system overpressuring when the storage is hot. I know my design isnt the best but it would be very difficult to change at this point. I have posted about this problem before but and I thought I had it under sontrol but it returned. This time I decided to post a diagram of the design.

I think the problem is that there are too many circs thus producing to much pressure but I wanted to see what you thought.

I have about 600 gal in the system. I have a Extrol SX-90 and a Extrol #90 expansion tanks. With everthing off, my pressure ranges from 12-15lbs. When storage is charged and circs are running, I can get pressures of 25-30. I have 2 relief valves. One on the boiler and one on the tank. The tank one weaps when I get around 30lbs. Never seem to have a problem with the boiler one.

What is your thought here. Is there any way to keep the pressure under control? I'm starting to think there may be a problem with the SX-90 even though its new.

I think the problem is that there are too many circs thus producing to much pressure but I wanted to see what you thought.

I have about 600 gal in the system. I have a Extrol SX-90 and a Extrol #90 expansion tanks. With everthing off, my pressure ranges from 12-15lbs. When storage is charged and circs are running, I can get pressures of 25-30. I have 2 relief valves. One on the boiler and one on the tank. The tank one weaps when I get around 30lbs. Never seem to have a problem with the boiler one.

What is your thought here. Is there any way to keep the pressure under control? I'm starting to think there may be a problem with the SX-90 even though its new.