About those fins on the exhaust blower, how do I clean those?

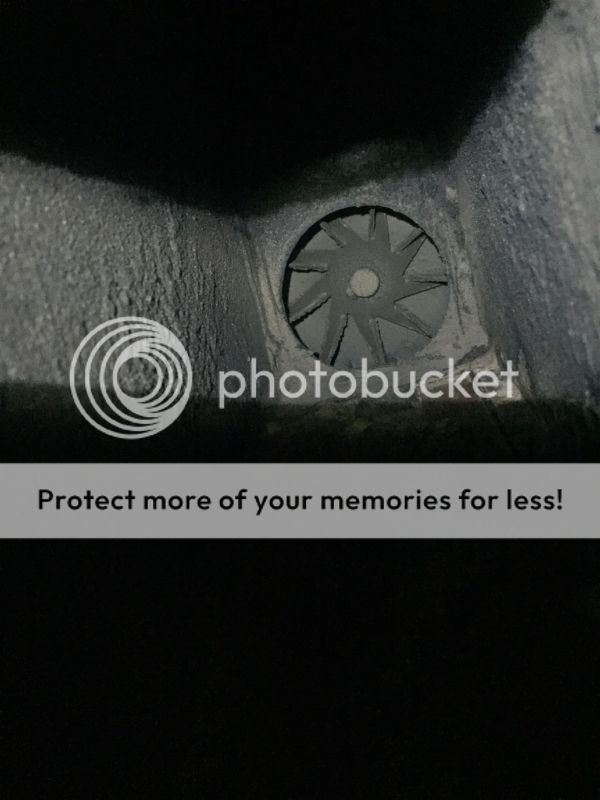

A shop vac hose with the crevice tool attached and a 1" soft bristle paint brush is what I use to clean and vacuum mine - some folks use a toothbrush. You can *gently* work the brush around between the fin blade plate and the blower motor shaft while you turn the blades with the brush to get the ash out that builds up there. See the pic below. Just go easy, as the fins can get easily bent, and then will wobble / vibrate or rub against the blower housing and impede the fan efficiency, or worse.

If you've never had the exhaust blower out to thoroughly clean it (recommended as a yearly maintenance) it may be crudded up with caked / consolidated fly ash. If the blower fins come clean with just brushing and vacuuming you can probably defer taking it out until the 'spring cleaning', after the burn season is over, which is when most folks do that.

The combustion blower is the 'engine' of the pellet stove 'forced draft' system, so it needs regular cleaning to maximize it's life span, which will eventually require replacement when the motor bearings inevitably fail over time and heat exposure.

If the fins are caked with hard fly ash it will require some *gentle*scraping, that will require taking the blower out (pg 34 in the manual) . I have a hand Dremel tool that I use with a small wire brush wheel that works great - but you can use a small wire hand brush and a small putty knife to get that build-up off. You'll need a new replacement gasket if you do take the blower out, as the old one inevitably tears when taking the blower out. This maintains the blower's air seal to keep smoke from leaking out into the room.

They're making reusable exhaust blower gaskets for some Quad stove models now, like the Mt Vernon, but I don't know if your Quad CB model has those available yet.

Once the blower fins are clean and shiny again, I spray them with some high temp graphite spray, which seems to help prevent the ash from building up on them.

I don't know what your comfort level is with DIY mechanical stuff beyond the routine cleanings, but what I did my first burn year was hire my reputable local Quad dealer to come and do the annual maintenance on my stove. I watched him like a hawk to see how and what he did to clean and 'tune up' the stove.

Then, with the help of other knowledgeable and patient Quad folks on this fine forum, and some good on-line Quad videos (here's one for your stove),

http://www.quadrafire.com/Owner-Resources/Use-and-Care-Videos/Classic-Bay-1200-Pellet-Stove.asp. , I was confident taking on all the maintenance and repair tasks. But everybody has to find their own comfort level with what they are willing to take on at a DIY level.

Knowing little more about pellet stoves when I started beyond "you put the pellets in the top end and take the ash out of the bottom end", if I can do it, anyone can !

Good luck, and hope this info helps.