I have a Slant/Fin Oil Boiler with a Honeywell L8124L Aquastat which heats 4 zones (cast iron rads) and an indirect hot water tank. I just installed a new Kerr Highlander wood boiler in parallel which is working great.

My problem is with the existing circulator that is installed in the return to the oil boiler. Its basically the main circulator for all the zones. It is connected into the Honeywell L8124L aquastat on the oil boiler. The aquastat's settings are 170 high, 150 low and 15 differential. When the wood boiler is running, I have a relay wired in to the oil burner power to shut it off (controlled by an aquastat on the wood boiler).

What I am finding is that the main circulator is not running when there is a call for heat from one of the zones, and the oil boiler is up to temp (when wood boiler is running). The circulator runs sometimes, so I know its working, but not all the time. If I adjust the differential on the L8124 aquastat either up or down, it will turn on.

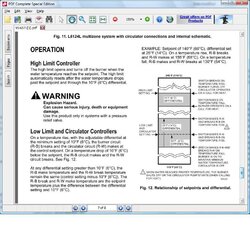

I just do not get when the circulator is supposed to run off this aquastat. I believe there is a difference depending on whether the temp in the boiler is rising or falling The manual for the aquastat is shown below. Using the settings above, can you tell me when (at what temp) the circulator should be running (on a call for heat)?

My problem is with the existing circulator that is installed in the return to the oil boiler. Its basically the main circulator for all the zones. It is connected into the Honeywell L8124L aquastat on the oil boiler. The aquastat's settings are 170 high, 150 low and 15 differential. When the wood boiler is running, I have a relay wired in to the oil burner power to shut it off (controlled by an aquastat on the wood boiler).

What I am finding is that the main circulator is not running when there is a call for heat from one of the zones, and the oil boiler is up to temp (when wood boiler is running). The circulator runs sometimes, so I know its working, but not all the time. If I adjust the differential on the L8124 aquastat either up or down, it will turn on.

I just do not get when the circulator is supposed to run off this aquastat. I believe there is a difference depending on whether the temp in the boiler is rising or falling The manual for the aquastat is shown below. Using the settings above, can you tell me when (at what temp) the circulator should be running (on a call for heat)?