Hello,

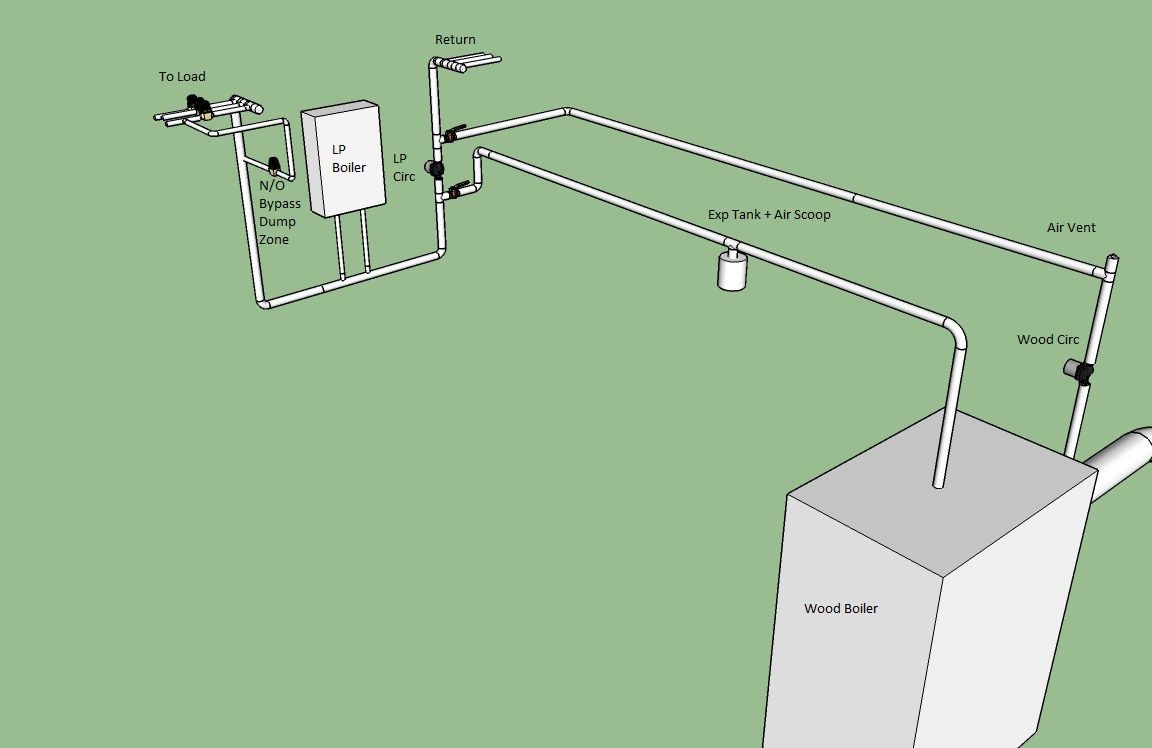

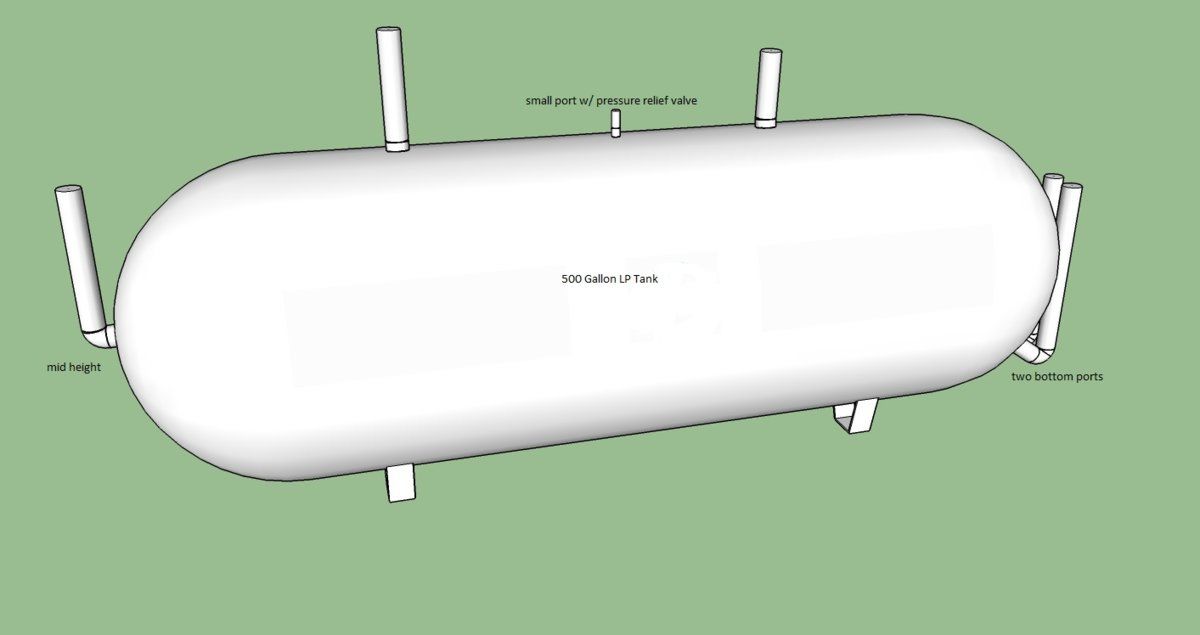

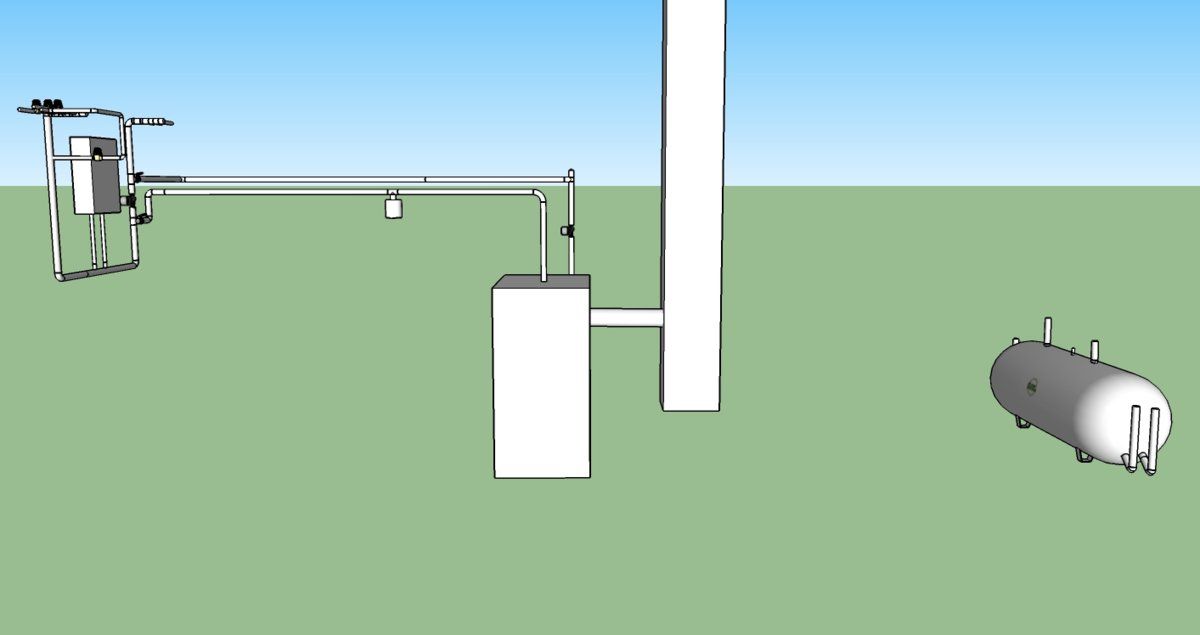

Currently I have an old Franks Philip wood boiler supplementing my propane boiler. The configuration is shown in the current_boiler.jpg attached image. It works okay, but it idles a lot and I have to cut my firewood 12". I also do not have a boiler protection bypass loop and I know my dump zone doesn't work well. This summer I purchased a used EKO 25 with all the controls and a 500 gallon storage tank. The location of the ports in the tank aren't ideal. They are shown in tank.jpg. The tank is in the opposite direction of the load, as shown in boiler_unconnected_tank.jpg. I know I could just loop from the wood boiler to the tank and then have a separate loop from the tank to the load, but I would like to be able to heat the load directly from the wood boiler if the house is calling for heat and the wood boiler is up to temp. What's the best way to accomplish this with my setup?

Thanks in advance,

Nathan

Currently I have an old Franks Philip wood boiler supplementing my propane boiler. The configuration is shown in the current_boiler.jpg attached image. It works okay, but it idles a lot and I have to cut my firewood 12". I also do not have a boiler protection bypass loop and I know my dump zone doesn't work well. This summer I purchased a used EKO 25 with all the controls and a 500 gallon storage tank. The location of the ports in the tank aren't ideal. They are shown in tank.jpg. The tank is in the opposite direction of the load, as shown in boiler_unconnected_tank.jpg. I know I could just loop from the wood boiler to the tank and then have a separate loop from the tank to the load, but I would like to be able to heat the load directly from the wood boiler if the house is calling for heat and the wood boiler is up to temp. What's the best way to accomplish this with my setup?

Thanks in advance,

Nathan