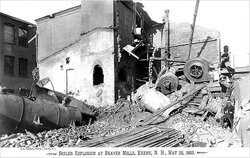

I was just writing to someone about my Tarm boiler experience, which last winter included an overheat/overpressure/relief valve failure event. And I suddenly realized that I have an obligation to pass along my experience and learning, because things may have turned out much more poorly. Looks like this is a good forum for that.

While burning wood in my mid '80's vintage Tarm 502 one Saturday last winter, I inadvertently left my lower door cracked open. The boiler water temp and pressure continued to build well above 200° and actually

exceeded the 30 PSI relief setting of my safety relief valve by the time my wife noticed something wrong. After realizing what had caused the problem, I first closed the door and opened up a couple of hot water valves in the house to help drop the boiler temp (my boiler has a domestic hot water coil). I then made sure the relief valve blowoff piping was directed well away from me, protected myself from a possible steam burn, and manually lifted the relief lever. Pretty scary result as the ~260° water instantly flashed off and filled my small boiler room with steam, but I felt at that point that it was better than risking a disastrous pressure part failure. The learning I got from that sobering event was:

• Test the relief valve annually (or more often if that is what the boiler or relief valve manufacturer recommends). I hadn’t exercised the lever in several years, partly because I figured “it may not re-seat tightly, and if so I’ll have to buy and install a replacementâ€. Sometimes a man can be too cheap for his own good! "Penny-wise and pound foolish" is another way to put it. Those relief valves aren't free, but they're a hell of a lot cheaper than hospital stays or funerals.

•

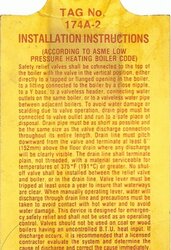

Do not install the relief valve horizontally, as it lends itself to deposition around the valve disk and seat which can cause the disk to seize. That is exactly what happened in my case, and because I hadn’t exercised it regularly, it didn’t open when needed. My boiler came with a horizontally mounted relief valve, and in fact, my Tarm owners manual actually has a photograph of the valve improperly installed. Perhaps that wasn’t considered a problem back when the boiler was made, but I’m now fully on board with the vertical installation that Watts recommends. In fact, I'll attach a photo of the attached tag on my Watts relief valve that spells it out quite clearly. And since I'm not an "expert", here's a link to a Bell&Gosset; page on the topic:

http://www.bellgossett.com/homeowners/gpart1.htm

Of course, I wouldn't have subjected my heating system to an overheat/overpressure situation had I made certain the door was tightly latched when I had loaded it up, and I have thought about installing a "door ajar" warning light on the boiler. I would be interested in reading about devices others have used to assist feeble-minded folks like me. But stuff like that is why relief valves were invented and regulations like the ASME Low Pressure Heating Boiler Code were written.