This 5 minute baffle plate install is the easiest way I've found to reduce smoke and prevent intense heating of the rear outlet elbow or pipe. (20 years late, but better late than never) And possibly the best solution for anyone who can't afford to upgrade to a new stove; Approximate cost under $25.

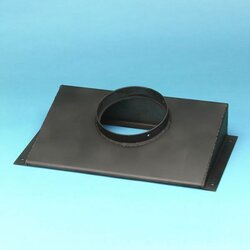

This pertains to a rear vent, but can be altered for a top vent as well. Simply measure across the inside of your stove width. Obtain a piece of steel plate 5/16 thick from a local steel fabricator or supplier 1/2 inch shorter than this measurement. I made mine (15 long X 8 inches wide for a Mama Bear. Mine cost 1.42 / lb. weighing 11 lbs. Cost $15.62) The only other materials required are 2 firebricks available at mason supply or stove retailer. (the type that line your stove 4 1/2 X 9 X 1 1/4 thick) Papa is the same height stove for brick supports, just a little longer plate to reach across the stove.

1). Simply set the firebrick on edge against the side walls on top of the first course a couple inches from the rear wall. Upright for a Mama or Papa works great, sideways for Baby.

2). Insert the plate through the door, tilt it sideways and rotate until it is between the side walls.

Raise it to the top, and set it on top of the firebrick.

3). By sliding it rearward, you can let it tip down in the back until it's at about a 45* angle in front of the rear vent. Many rear vented stoves have a short shelf under the outlet pipe to set it on as well.

4). Make sure the opening above the plate to stove top is an acceptable size opening.

This can be adjusted by moving the bricks fore and aft to change the angle and opening if required.

The only technical measurement is the opening above the baffle plate. This must be at least as large as the square inch area of your outlet. (6 inch round formula is pi X r squared or 3.14 X 9 =28.26" square inch opening. An 8 inch Grandma or Grandpa would be 3.14 X 16 or 50.24 square inch opening) This is about 2 inches from the top, all the way across any model Fisher Stove. You can adjust it to your exact size, but I find it doesn't make much difference making the opening exact.

I found once in place, this is quite solid and doesn't want to move. It also doesn't noticeably decrease firebox size.

The intense heat that normally would heat the rear outlet elbow now goes up the plate and burns the unburned smoke particles before they get to the outlet. This also directs the heat to the stove top instead of in the direction of the exhaust. (rearward) Huge reduction in smoke. (about 90% reduction as calculated in EPA testing with and without baffle) Nothing permanent is added to the stove. This would also be the perfect area to add a secondary burn tube to admit oxygen at this hottest area.

I was going to fabricate an angle iron frame to support a baffle plate, and realized I had some old firebrick laying around that the plate could set on instead. Much cheaper than angle iron, and some single door stoves use this second course of brick above the first at the rear anyway. I positioned the new baffle plate that cost a total of $16 and 2 bricks in the stove in less than 5 minutes. I expected to need to cut the corners of the bricks on angles, but the plate sat right on the full bricks in the Mama Bear shown below. Extremely simple !

This pertains to a rear vent, but can be altered for a top vent as well. Simply measure across the inside of your stove width. Obtain a piece of steel plate 5/16 thick from a local steel fabricator or supplier 1/2 inch shorter than this measurement. I made mine (15 long X 8 inches wide for a Mama Bear. Mine cost 1.42 / lb. weighing 11 lbs. Cost $15.62) The only other materials required are 2 firebricks available at mason supply or stove retailer. (the type that line your stove 4 1/2 X 9 X 1 1/4 thick) Papa is the same height stove for brick supports, just a little longer plate to reach across the stove.

1). Simply set the firebrick on edge against the side walls on top of the first course a couple inches from the rear wall. Upright for a Mama or Papa works great, sideways for Baby.

2). Insert the plate through the door, tilt it sideways and rotate until it is between the side walls.

Raise it to the top, and set it on top of the firebrick.

3). By sliding it rearward, you can let it tip down in the back until it's at about a 45* angle in front of the rear vent. Many rear vented stoves have a short shelf under the outlet pipe to set it on as well.

4). Make sure the opening above the plate to stove top is an acceptable size opening.

This can be adjusted by moving the bricks fore and aft to change the angle and opening if required.

The only technical measurement is the opening above the baffle plate. This must be at least as large as the square inch area of your outlet. (6 inch round formula is pi X r squared or 3.14 X 9 =28.26" square inch opening. An 8 inch Grandma or Grandpa would be 3.14 X 16 or 50.24 square inch opening) This is about 2 inches from the top, all the way across any model Fisher Stove. You can adjust it to your exact size, but I find it doesn't make much difference making the opening exact.

I found once in place, this is quite solid and doesn't want to move. It also doesn't noticeably decrease firebox size.

The intense heat that normally would heat the rear outlet elbow now goes up the plate and burns the unburned smoke particles before they get to the outlet. This also directs the heat to the stove top instead of in the direction of the exhaust. (rearward) Huge reduction in smoke. (about 90% reduction as calculated in EPA testing with and without baffle) Nothing permanent is added to the stove. This would also be the perfect area to add a secondary burn tube to admit oxygen at this hottest area.

I was going to fabricate an angle iron frame to support a baffle plate, and realized I had some old firebrick laying around that the plate could set on instead. Much cheaper than angle iron, and some single door stoves use this second course of brick above the first at the rear anyway. I positioned the new baffle plate that cost a total of $16 and 2 bricks in the stove in less than 5 minutes. I expected to need to cut the corners of the bricks on angles, but the plate sat right on the full bricks in the Mama Bear shown below. Extremely simple !