anyone have experience with a snowblower friction plate (not wheel) that won't move when the handle lever is engaged? The plate will not move toward the friction wheel to transfer power to the wheels.

snowblower friction plate won't move

- Thread starter mepellet

- Start date

-

Active since 1995, Hearth.com is THE place on the internet for free information and advice about wood stoves, pellet stoves and other energy saving equipment.

We strive to provide opinions, articles, discussions and history related to Hearth Products and in a more general sense, energy issues.

We promote the EFFICIENT, RESPONSIBLE, CLEAN and SAFE use of all fuels, whether renewable or fossil. -

Super Cedar firestarters 30% discount Use code Hearth2024 Click here

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

- Status

- Not open for further replies.

heat seeker

Minister of Fire

What brand? My Ariens and ancient Craftsman move the rubber wheel toward the plate, which is fixed axially.

Seems like having the plate move would involve splines, etc., and it would be cheaper to move the rubber wheel.

Pictures might help.

Seems like having the plate move would involve splines, etc., and it would be cheaper to move the rubber wheel.

Pictures might help.

Its an ariens. Model st724. It frees up after taking the bottom plate off and tapping on it and turning it manually with my hands. I'll try taking pictures tonight.

heat seeker

Minister of Fire

Is there a grease fitting? If it's supposed to slide on a splined shaft, it may need a bit of grease. Sounds like it's binding on the shaft.

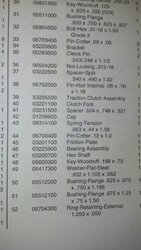

That sounds very possible but to be honest I don't know much at all about these kind of things. Does adding grease require dissembling anything? I can take some pictures of the area and of the exploded parts diagram.

heat seeker

Minister of Fire

IF there is a grease fitting, it should be readily accessible with the bottom plate off. You might have to rotate the plate by hand to get at it.

Pics and the diagram would be quite helpful, yes.

ETA - I looked up some service manuals for Ariens, and they all seem to move the rubber disk, not the drive plate, but it's hard to tell from the diagrams. Have you adjusted the drive linkage as per the manual?

Pics and the diagram would be quite helpful, yes.

ETA - I looked up some service manuals for Ariens, and they all seem to move the rubber disk, not the drive plate, but it's hard to tell from the diagrams. Have you adjusted the drive linkage as per the manual?

Can you send me the manual you are looking at? The one I have doesn't cover adjusting the drive linkage. I appreciate the help!IF there is a grease fitting, it should be readily accessible with the bottom plate off. You might have to rotate the plate by hand to get at it.

Pics and the diagram would be quite helpful, yes.

ETA - I looked up some service manuals for Ariens, and they all seem to move the rubber disk, not the drive plate, but it's hard to tell from the diagrams. Have you adjusted the drive linkage as per the manual?

heat seeker

Minister of Fire

It sort of looks like the plate may slide on the hex of the shaft (the hex acting as a spline). I can't see if there is a grease fitting or not. Either spring 39 or 43 must exert pressure to push the rubber against the plate.

So, look for a grease fitting on part 45, near the hub. Also check for binding anywhere in the linkage, and the adjustments - there should be some free play in the mechanism to allow the spring(s) to push the rubber and plate together. It might just take a drop or two of oil on the pivot points of the clutch mechanism.

So, look for a grease fitting on part 45, near the hub. Also check for binding anywhere in the linkage, and the adjustments - there should be some free play in the mechanism to allow the spring(s) to push the rubber and plate together. It might just take a drop or two of oil on the pivot points of the clutch mechanism.

heat seeker

Minister of Fire

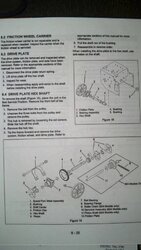

Don't know if this your model or not, but the procedure should be the same:

http://apache.ariens.com/manuals/024532.pdf

Page 6, right side.

Glad to be of some help.

http://apache.ariens.com/manuals/024532.pdf

Page 6, right side.

Glad to be of some help.

heat seeker

Minister of Fire

I missed your post #9 - it does look like the plate is supposed to move, after all. They mention putting anti-sieze on the hex of the shaft, so it appears there is motion between the two. I would not expect to see a grease fitting, then. You may have to disassemble the drive to get the plate off, clean the hex, and apply some anti-sieze on the hex.

You might get through with applying some penetrating oil in the hex area, but don't let it run onto the friction surface, for obvious reasons. This has been educational for me, I've never seen this particular setup.

You might get through with applying some penetrating oil in the hex area, but don't let it run onto the friction surface, for obvious reasons. This has been educational for me, I've never seen this particular setup.

I missed your post #9 - it does look like the plate is supposed to move, after all. They mention putting anti-sieze on the hex of the shaft, so it appears there is motion between the two. I would not expect to see a grease fitting, then. You may have to disassemble the drive to get the plate off, clean the hex, and apply some anti-sieze on the hex.

You might get through with applying some penetrating oil in the hex area, but don't let it run onto the friction surface, for obvious reasons. This has been educational for me, I've never seen this particular setup.

Thanks for the help heat seeker! I will attempt to use some penetrating oil to get me through the winter. Taking apart things like this takes me way too long so I'll save that for the summer. I truly appreciate the help.

heat seeker

Minister of Fire

You're welcome, let us know how it comes out. I wouldn't be too anxious to take it apart this time of year, either!

Retired Guy

Minister of Fire

After one winger of blowing slush, my JD had the same problem. The disc needed to move about a half inch to fully engage the friction wheel. The disc was rusted in place, spray of PB and some lube took care of the problem.

Well I gave three beating assembly a couple quick shots of Wd-40 after getting it free on Saturday night. Remained unstuck overnight and was able to use it to clean up the driveway yesterday. This morning on the way out the door, I checked it and it was slightly stuck. While rolling the blower slowly I pushed down on the handle lever. At first it didn't stop the blower from moving but while keeping three handle lever depressed it came loose. Could feel the "click" in the lever. Do you think it just needs a good taking apart and cleaning then reassembling?

heat seeker

Minister of Fire

Yes, it sounds like it's crudded up. Make sure all of the linkage works okay, first. That's a lot easier to do..

Maybe just using it a bunch will free things up, too.

Maybe just using it a bunch will free things up, too.

When it was stuck I could see the spring on the linkage "extend." So I believe the linkage is all working ok. I wonder if just exercising the handle lever and linkage a couple times a day this winter will keep everything loose enough to hold me over until the spring when I can take it apart.

heat seeker

Minister of Fire

I wonder if just exercising the handle lever and linkage a couple times a day this winter will keep everything loose enough to hold me over until the spring when I can take it apart.

Can't hurt, time will tell…I'm out of clichés...

M

MasterMech

Guest

Remove the belly pan and lube the shaft/linkage that the plate pivots on. Use a good water-displacing penetrating lube. Make sure there is no mouse nest in there.

I have a different Ariens model, but as others have said the first and easiest thing to do is check the linkage/spring adjustment. On mine, it is adjusted by measuring the distance from the disc engagement lever to the handlebar when the disc hits the firction plate. It doesnt sound like what you are experiencing, but thats where i would start.

Thanks. I will double check this. On mine, the friction plate moves back towards the operator to make contact with the friction disc.I have a different Ariens model, but as others have said the first and easiest thing to do is check the linkage/spring adjustment. On mine, it is adjusted by measuring the distance from the disc engagement lever to the handlebar when the disc hits the firction plate. It doesnt sound like what you are experiencing, but thats where i would start.

I did talk to a local Ariens repair place the other day and he didn't give me a written quote but said that it sounded like a couple small parts needed to be replaced and it would cost around $200 to fix. I still think it is just the friction plate freezing up on the hex shaft and needs to be taken apart, cleaned, lubed and put back together. Hoping to get by with just some WD-40 and until the spring when I can take it apart and do a good cleaning.

Toss the WD-40 for this application. Get an actual lubricant (liquid wrench has a can of sprayable oil)

(I have nothing against WD, but it ain't worth squat as a long term lube.).

(I have nothing against WD, but it ain't worth squat as a long term lube.).

- Status

- Not open for further replies.

Similar threads

- Replies

- 5

- Views

- 737

- Replies

- 3

- Views

- 862

- Replies

- 2

- Views

- 457