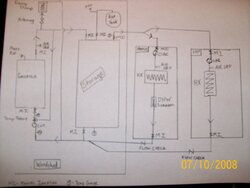

WB is to be an Eko 40.

Our shop is 60 feet from the woodshed where the boiler will be located.

The house is 90 feet out in a different direction.

Try as I wanted to avoid using three circs it appears that I will have too much head in the system to do it otherwise. Also there is a bit of elevation difference between the planned shop hx location and the house loads in the basement.

I'm still in the purchasing stage so there is time to change any large issues that can be seen. The woodshed is under construction & I'm buying the other components as I can. The boiler gets ordered next week if we make enough shed progress this weekend...

Oh yeah, I apologize for the bad pic.

Thanks

Our shop is 60 feet from the woodshed where the boiler will be located.

The house is 90 feet out in a different direction.

Try as I wanted to avoid using three circs it appears that I will have too much head in the system to do it otherwise. Also there is a bit of elevation difference between the planned shop hx location and the house loads in the basement.

I'm still in the purchasing stage so there is time to change any large issues that can be seen. The woodshed is under construction & I'm buying the other components as I can. The boiler gets ordered next week if we make enough shed progress this weekend...

Oh yeah, I apologize for the bad pic.

Thanks