I have a US Stove 1537G wood furnace (119,000 Btu/hr) that is rated for heating up to 2500 Sq ft. My home is 1900 sq feet and I can't keep it heated. Most people I talk to tell me it should be cooking me out of the house. I've been on the phone with US Stove several times and they are out of suggestions for me. Here's the quick and dirty on what I have and what I have done:

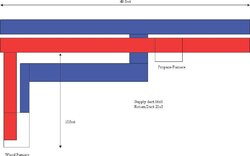

The wood furnace is a parallel installation with a propane furnace. It is phyically located about 20 feet from the propane furnace, but has about 30 ft of trunk line between them. All the main trunk line in the house is 16x8 rectangular. All the return duct is 20x8 retangular. I have 60 ft of supply trunk duct running the length of my house with the individual rooms running off of them. The wood furnace has (2) 550 cfm blowers. I have attached a picture of the installation. (I changed the 8" round duct out for 16x8 retangular duct since the picture was taken.)

The furnace itself seem to be operating ok in that I can acheive a good fire with 350-450 chimney temperature and a solid draft. Although I am getting short burn times, I think that may be a result of my wood being too dry. Regardless of that, I cannot seem to get a very good plenum temperature. My limit control is set to start the blowers at 175F and shut them down at 95F. Once the blowers kick on the plenum temperature almost immediately drops down to 130F and then slowers continues to drop until it settles in around 115F. It'll stay there until the fire dies down and I need to reload wood.

I have tried adjusting the under fire air and the over fire air in differant combinations, but I can't seem to keep a higher plenum temperature. If I really let the fire rip I can get about 140F in the plenum, but the wood burns so fast I'd have to relaod the furnace every couple hours to keep it there. I've installed a chimney damper as well to help keep heat in the furnace longer. That has helped some, but even with it almost shut I can't seem to get enough heat out of the furnace.

Has anyone else seen this problem? Any suggestions? Your help is greatly appreciated.

The wood furnace is a parallel installation with a propane furnace. It is phyically located about 20 feet from the propane furnace, but has about 30 ft of trunk line between them. All the main trunk line in the house is 16x8 rectangular. All the return duct is 20x8 retangular. I have 60 ft of supply trunk duct running the length of my house with the individual rooms running off of them. The wood furnace has (2) 550 cfm blowers. I have attached a picture of the installation. (I changed the 8" round duct out for 16x8 retangular duct since the picture was taken.)

The furnace itself seem to be operating ok in that I can acheive a good fire with 350-450 chimney temperature and a solid draft. Although I am getting short burn times, I think that may be a result of my wood being too dry. Regardless of that, I cannot seem to get a very good plenum temperature. My limit control is set to start the blowers at 175F and shut them down at 95F. Once the blowers kick on the plenum temperature almost immediately drops down to 130F and then slowers continues to drop until it settles in around 115F. It'll stay there until the fire dies down and I need to reload wood.

I have tried adjusting the under fire air and the over fire air in differant combinations, but I can't seem to keep a higher plenum temperature. If I really let the fire rip I can get about 140F in the plenum, but the wood burns so fast I'd have to relaod the furnace every couple hours to keep it there. I've installed a chimney damper as well to help keep heat in the furnace longer. That has helped some, but even with it almost shut I can't seem to get enough heat out of the furnace.

Has anyone else seen this problem? Any suggestions? Your help is greatly appreciated.