I've read a lot on here and elsewhere about using vents, HVAC and fans for moving hot air around with mixed results, usually poorly.

My house is a modular with a basement stove install at the very far end, not ideal for 56' long. It was built with small ducts on each side of the house that ran lengthwise but one was never utilized. I panned off a bay between the floor joists in the stove room, tapped into the trunk and brought the other end down to my air handler in another room with 30 foot of 8" flext duct.

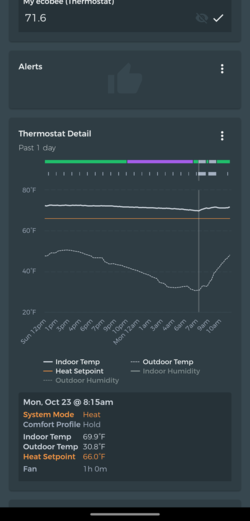

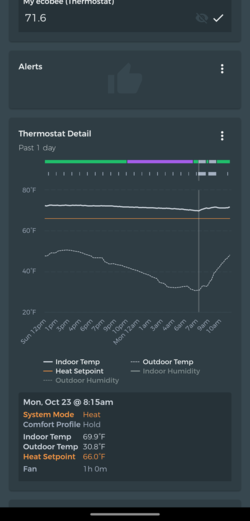

It does work pretty well but maybe not as much as I was expecting but I may have just been unrealistic. Air at the ceiling above the stove can get to 90f. When I run the air handlers fan I can see the vents go up 2.5-5 degrees depending on temps. I can see the thermostat slowly climb when running the fan. Worth the effort and $150 in materials IMO.

My house is a modular with a basement stove install at the very far end, not ideal for 56' long. It was built with small ducts on each side of the house that ran lengthwise but one was never utilized. I panned off a bay between the floor joists in the stove room, tapped into the trunk and brought the other end down to my air handler in another room with 30 foot of 8" flext duct.

It does work pretty well but maybe not as much as I was expecting but I may have just been unrealistic. Air at the ceiling above the stove can get to 90f. When I run the air handlers fan I can see the vents go up 2.5-5 degrees depending on temps. I can see the thermostat slowly climb when running the fan. Worth the effort and $150 in materials IMO.