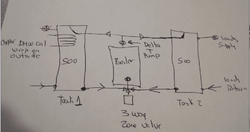

Here is a concept that is common with solar thermal, multi tank loading. i've seen this done with up to 6 individual tanks.

The goal is to keep the collectors, or boiler in your case, at it's most efficient operating condition. That being with the coolest return temperature operation. 130F and above of course for wood boilers, solar doesn't have return temperature issues.

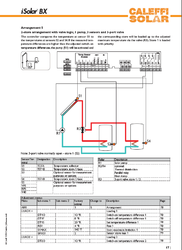

It involves a 3 way zone valve with a delta t (solar) controller. The tank with the lowest temperature is supplied first. It is heated until it is 10F above the other tank. then loading will be done alternately.

Furthermore the pump used to load these could be modulated with a variable speed function. The pump would not start loading until the boiler is up to temperature 140F or so, for your "anti dew" protection.

Supply to the loads is pulled from the top of the tanks.

I'd wrap 60 feet of 3/4 copper tightly around the upper part of one tank as a DHW pre-heat.

It depends on what temperature you can use to your heat emitters as to how I would pull that off. Ideally an outdoor reset function would be used to pull only the temperature you need to meet the load. This maximizes your tanks "useable" energy best.

If in fact you could heat the home with supplies of 120F you now have a 60 degree delta T tank range. charge them to 180F, draw down to 120F. I've posted a few different options for low temperature heat emitters in the past. radiant slab best, low temperature panel rads or that low temperature baseboard, or Jaga fan assisted panel rads.

DHW boost could be via an indirect tank if you want, tankless, whatever.

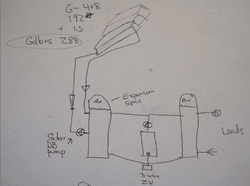

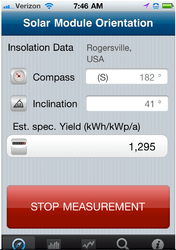

solar could be tied into this arrangement also to cover DHW summer loads for that I would include a mid point port in one of the tanks so a small array 40- 80 square feet would only see part of one tank as it's load.

A bit more involved piping would include a parallel piping that allowed heat energy to go directly to the loads without heating either tank until the load satisfies, then the tanks start their charge. That too could be a priority function that assured the load could always be covered even before the tanks get up to final temperature.

My overheat method, if i even worried about it would be to fire a low priority zone in the home to drop the system temperature to a comfortable point, maybe 190F on, 185F off. This could also be a circ with a battery backup for power outage protection.

hr