Thank again for that! Ceiling fans are already cabled up - a huge one in the great room and a slightly smaller on in the loft and we air supply is also being handled. Appreciate you flagging these for me. Anything else we need to think about? The one other issue that I have been pondering is how many straps we will need to secure the chimney pipe. We have a LOT of wind every morning and installing a cap that is for high wind is already being planned --- but how many straps one needs is not clear yet since I don't know how the chimney pieces are connected and how stable these connections are. I guess we will find out when the parts arrive...

Where to put the "T" for installation through the wall - does it have to be mounted to the wall?

- Thread starter Chestnutty

- Start date

-

- Tags

- through the wall

-

Active since 1995, Hearth.com is THE place on the internet for free information and advice about wood stoves, pellet stoves and other energy saving equipment.

We strive to provide opinions, articles, discussions and history related to Hearth Products and in a more general sense, energy issues.

We promote the EFFICIENT, RESPONSIBLE, CLEAN and SAFE use of all fuels, whether renewable or fossil.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

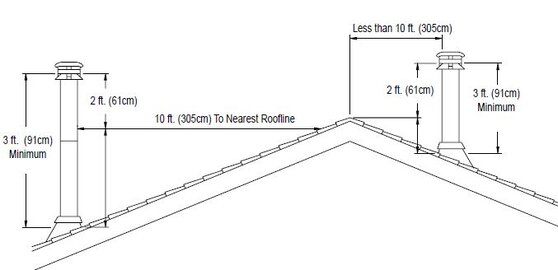

It depends on the exterior chimney exposure. The chimney must have a roof brace at 5' above the roof. The chimney height will be determined by the 10-3-2 rule.Thank again for that! Ceiling fans are already cabled up - a huge one in the great room and a slightly smaller on in the loft and we air supply is also being handled. Appreciate you flagging these for me. Anything else we need to think about? The one other issue that I have been pondering is how many straps we will need to secure the chimney pipe. We have a LOT of wind every morning and installing a cap that is for high wind is already being planned --- but how many straps one needs is not clear yet since I don't know how the chimney pieces are connected and how stable these connections are. I guess we will find out when the parts arrive...

I am not sure I ever understood this one despite my best efforts --- My understanding is that the chimney, irrespective of how far the distance from the nearest roofline, has to extend 2 ft above the roofline... how the 10 ft come into this is not clear and the above drawing also does not show it... our chimney will be around 8 ft to the roof line then another 2 feet above if I understand correctly. So we have to sercure 10 ft of pipe--- I would assume that requires more than one support brace? one at the roofline and one below?It depends on the exterior chimney exposure. The chimney must have a roof brace at 5' above the roof. The chimney height will be determined by the 10-3-2 rule.

View attachment 325468

The height will be determined by its location relative to the slope of the roof. The chimney must end at least 3' above the roof and at least 2' above any portion of the roof within 10'. If a chimney location closer to the ridge is desired, an offset could be put in the stovepipe to do this.

the distance between where the chimney exits the roof and the roofline for us will be around 9 1/2 ft... so we have to go 3 ft above the roofline, not 2 ft......The height will be determined by its location relative to the slope of the roof. The chimney must end at least 3' above the roof and at least 2' above any portion of the roof within 10'. If a chimney location closer to the ridge is desired, an offset could be put in the stovepipe to do this.

No you need to go 2 feet above anything within 10 feet. Your roof is a 10/12 pitch. So at 10 feet away the roof will rise by 100". So your chimney would have to be 124" minimum unless the ridge is closer than 10'. In that case it would simply be 24" higher than the ridge.the distance between where the chimney exits the roof and the roofline for us will be around 9 1/2 ft... so we have to go 3 ft above the roofline, not 2 ft......

Typically you would need a roof support for every 5' of chimney that is above the roof. So if you have over 10' you will need 2 under 10' only 1

all night moe

Minister of Fire

I like the flashing posted by begreen. One of my trades is in roofing. Once a standing seam roof is installed, it should not be disturbed. How to tie in the top of this flashing in the field of the roof? I'd put the chimney at the ridge where the top of that flashing can be terminated under the ridge cap. Ridge cap is pressure fit with z-farrow to secure and can be removed/reinstalled.

I believe this is why those silicone roof boots are made, for mid roof installs. I completely despise those altogether. Ugly and look like they should be for commercial apps. I dislike roof penetrations sealed non mechanically.

I believe this is why those silicone roof boots are made, for mid roof installs. I completely despise those altogether. Ugly and look like they should be for commercial apps. I dislike roof penetrations sealed non mechanically.

The upper edge of the flashing slips under the top edge of the metal cut or if at the ridge, under the ridge cap.How to tie in the top of this flashing in the field of the roof?

This is one under the ridge cap. This is before the storm collar has been installed. Note that the bottom is not sealed. That is more typical of what I have seen. The reason is to allow any trapped moisture to drain.

There are a few ugly things about the silicone boots. One is that they age over time in the sun, second is that they offer little support for the chimney pipe, and they require over a ton of screw holes to anchor them down.

This is another style metal roof flashing. Ventis?

Where is this house located? I'd put an offset in the stove pipe, especially if high winds are also a common issue. What is the maximum amount of snow planned for? If >12" then a cricket (diverter) above the flashing may be advised.the distance between where the chimney exits the roof and the roofline for us will be around 9 1/2 ft... so we have to go 3 ft above the roofline, not 2 ft......

Just spitballing here, have alternative locations for the stove been considered?

Last edited:

all night moe

Minister of Fire

IMHO, that is destined to fail. All the pics you showed are screw down roofs with the exception of the last pic, being a standing seam.The upper edge of the flashing slips under the top edge of the metal cut or if at the ridge, under the ridge cap

In the 1st pic, red roof, the flashing could be installed with a regular flashing kit. Then the roof could be re fitted with a new panel above, cut to fit in. As done, the upper corners lack coverage. The top is silicone sealed which will fail under a couple years of UV exposure. Especially when a hot metal roof is baking it.

I prefer a standing seam. A well done job will last for decades.... and decades. I've been on some old farmhouses and barns with the original roofs from a hundred plus years ago, with minimal maintenance. That said, screw down roofs are a lighter grade metal and have non mechanically joined seams. The neoprene washers, on the screws, will fail from UV exposure in 15-20yrs. The benefit is these roofs can be taken apart for roof altercations. When installing standing seam, all penetrations need to be well planned in advance or, already existing.

I wish the last pic showed the install of the pipe flange. I would bet it was installed during constructing the roof.

On the red roof the top is slipped under the existing roof. I don't know why they siliconed everything one little dab where the flashing comes out of the roof is all that's needed. Yes absolutely if you have matching roof panels that I the best way. But if it's older there is no way to match itIMHO, that is destined to fail. All the pics you showed are screw down roofs with the exception of the last pic, being a standing seam.

In the 1st pic, red roof, the flashing could be installed with a regular flashing kit. Then the roof could be re fitted with a new panel above, cut to fit in. As done, the upper corners lack coverage. The top is silicone sealed which will fail under a couple years of UV exposure. Especially when a hot metal roof is baking it.

I prefer a standing seam. A well done job will last for decades.... and decades. I've been on some old farmhouses and barns with the original roofs from a hundred plus years ago, with minimal maintenance. That said, screw down roofs are a lighter grade metal and have non mechanically joined seams. The neoprene washers, on the screws, will fail from UV exposure in 15-20yrs. The benefit is these roofs can be taken apart for roof altercations. When installing standing seam, all penetrations need to be well planned in advance or, already existing.

I wish the last pic showed the install of the pipe flange. I would bet it was installed during constructing the roof.

all night moe

Minister of Fire

Silicone or none, there still is not enough coverage at the sides of the top corners. Not enough overlap between panel and flange.On the red roof the top is slipped under the existing roof. I don't know why they siliconed everything one little dab where the flashing comes out of the roof is all that's needed.

Usually that is the case. Slight variations between manufactures and fading of older panels. Good thing is, color variations are sometimes not noticeable from the ground level. Even when they are, I usually find the HO to ecstatic of a professional flange install.But if it's older there is no way to match it

What do you mean. There is lots of overlap if it's done properly.Silicone or none, there still is not enough coverage at the sides of the top corners. Not enough overlap between panel and flange.

Usually that is the case. Slight variations between manufactures and fading of older panels. Good thing is, color variations are sometimes not noticeable from the ground level. Even when they are, I usually find the HO to ecstatic of a professional flange install.

I can easily do a professional install that doesn't leak without using a new piece of roofing

all night moe

Minister of Fire

In the pick of the red roof, the flange looks to have minimal coverage on the sides, going under the roof, at the top corners.What do you mean. There is lots of overlap if it's done properly.

I can easily do a professional install that doesn't leak without using a new piece of roofing

What I was referencing earlier about a new panel is to add a new piece of roof at the top, above the flue. Not a whole length panel. This panel can be cut to overlap much of the flue's pipe flange. Hope this makes sense of what I'm describing.

Do you have a pic of the flange uninstalled? The one on the red roof.

Similar threads

- Replies

- 6

- Views

- 534

- Replies

- 8

- Views

- 5K

- Replies

- 0

- Views

- 1K

- Replies

- 4

- Views

- 659

This was driving me nuts lol

This was driving me nuts lol