- Mar 20, 2013

- 3

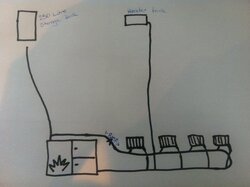

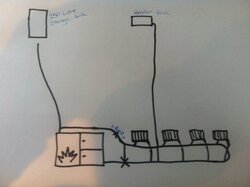

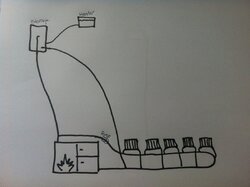

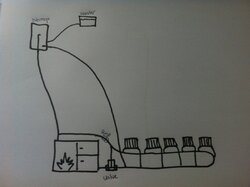

Hi there, I have installed an Esse W35 range cooker, and have linked it to a 250 litre storage cylinder and half a dozen radiators. We are having a lot of trouble with low flue temps, low oven temps and creosote/taring, it is obvious the return temps are putting too much load on the boiler and I am struggling to get it up to working temperature. I figure I need to put a loading valve in the line where I have marked on my diagrams and basically want to know if this is the right thing and place to put it, and if I need a full loading valve or just a mixing valve, an esbe ltc100 or laddomat or just a mixing valve like a esbe vtc300 series as we already have a pump inline.

I have the thermosyphon going to the storage tank which works really well, it will heat the whole tank in a short period and by doing this first before it starts circulating to the radiators, means that the cylinder is ready quicker if you wanted to take a shower.

Any input would be appreciated as it is a great cooker, just really want to get it ready for winter...it is still summer over here.

I have the thermosyphon going to the storage tank which works really well, it will heat the whole tank in a short period and by doing this first before it starts circulating to the radiators, means that the cylinder is ready quicker if you wanted to take a shower.

Any input would be appreciated as it is a great cooker, just really want to get it ready for winter...it is still summer over here.