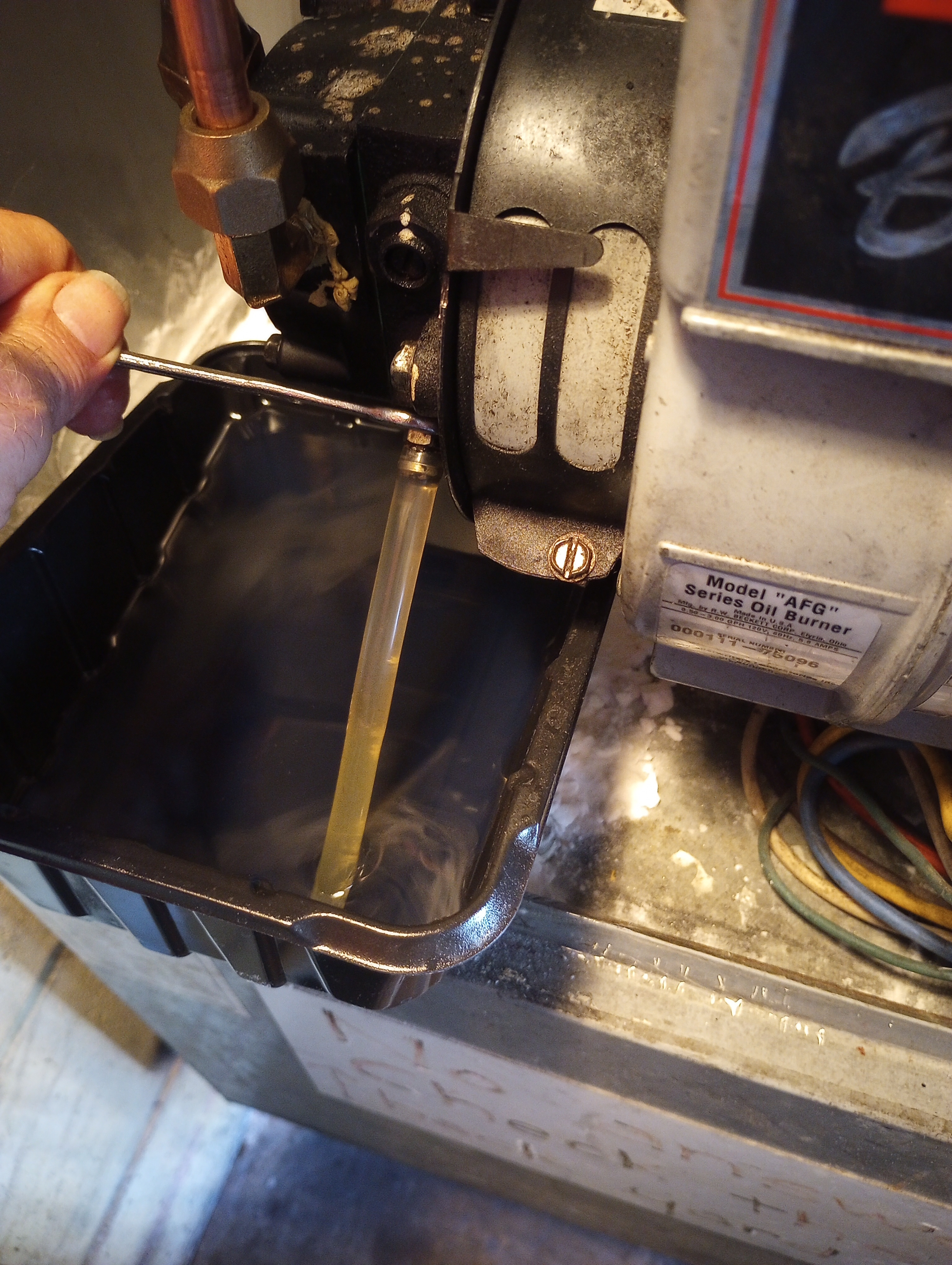

See pic. That is my current setup that gets air when i bleed it. Less then 1 second of tiny bubbles shortly after i open bleed port. Heater never cycled off for 45 minutes as i bleed it over and over. If the bleed was closed < 20 seconds, then no bubbles, but if it was open >30 seconds, there was tiny bubbles,but for less then 1 second. Several times I had it open for 30 to 45 seconds after bubbles stopped and never saw any more. Until i closed it for 30 or more seconds.

Ideas?

Ideas?