Rory said:

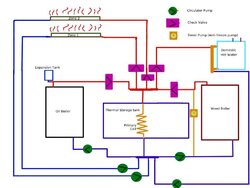

You know, I don't really get the concerns with using oil to heat storage. #1, it's set to kick in at a point we choose, which isn't going to be anything close to the temp it comes in from the well. #2, if the storage is insulated really well, any heat made will ultimately be used for its intended purpose. If the storage is inside and it's heating season, any loss goes into the house anyways. Where's the problem?

Like many things, it depends. Most of us are trying to burn as little oil as possible, usually for brief periods when we're not there to start the wood boiler. In my case, when that happens I want to use just enough oil to keep the house and/or DHW at temperature. The expectation is that I'll be starting the wood boiler again at some point in the not-too-distant future.

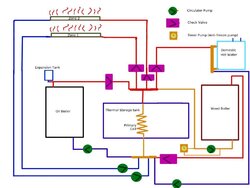

The oil boiler won't come on at all unless storage is too cold to heat the house. If the oil boiler has to heat storage before it can heat the house and/or DHW, then I'm going to have to burn a lot of oil to get a little bit of heat into my house.

I'll agree that he heat is not lost, but if I'm heating storage with oil I'm burning oil to reduce the amount of wood that I'll burn in the future. That's not what I want to do.