I'm new to this forum and have more than likely read this type of thread before at least two or three or four times but am starting it again to see if I'd missed something so here goes. I've got a USSC SP8500 multi fuel furnace going on its second season but it's the first season to use a thermostat. Before I lit the fire for first time this year (only been burning for three weeks at current time) I gave stove a real thorough cleaning and currently it's keeping a insulated two story with basement (2700sqft) house to 70 deg however here in southern Indiana today's high is 60-65 but tomorrow a cold front is coming through dropping us to highs of 40-45 for next seven days. I'm burning wood pellets and have the unit hooked up to a wall mounted thermostat set to 70 deg F. The unit is hooked into current duct work of home (both cold air intake and warm air discharge) and set to run both room fans when on HR3 or higher. I currently have it in auto mode (only use manual when I light fire), aux is in auto mode and draft fan is set to Auto but draft fan keeps surging and the flame in burn chamber is dancing around without any kind of coordination whether dampener is all the way in or all the way out or anywhere in between. Door temps on HR1 rarely get above 100 deg F and on HR3 they struggle to get 350 deg F but have not gone to any higher range yet. Currently I have HR1 set to burn 2lbs/hr and HR5 is set to 5.5lbs/hr. For a trial I set HR1 to 5lbs/hr and HR5 to 10lbs/hr the door temps never got above 350deg F. I'm well aware that more fuel equals more heat but when it's 50-60 deg outside I don't see the need to be pouring ton upon ton of fuel to it when there's pellet stoves like this in same operating conditions that keep homes to 70 deg at really low fuel rates. I've read manual many times plus read many forums and been watching many youtube videos on setting up the unit and have changed some of the operating constants (I have written record of all this) to match wood pellets as suggested in the forums and videos. I do not have an outside air kit to stove but basement (location of unit) is large and has some air leaks anyway. Where exhaust comes off unit it goes to a clean out 'T' than 45's to a 3ft 6in straight run than another 45 to a 16" straight tube going into a 8x12 clay lined chimney approx 25-30ft tall. All exhaust piping from unit to chimney is 3" insulated and adds up to about 4 1/2 to 5 feet total from stove outlet to where it goes into chimney. The chimney blocks feel warm to touch when unit is running but I feel the chimney is drafting to good if that's even a possibility. I appreciate your assistance and let me know what you think would be the best solution to get the operating temps and overall operation of unit squared away so I'm not just burning more pellets than needed without a cause. Thanks.

slow process

- Thread starter slowlymakingprogress

- Start date

-

Active since 1995, Hearth.com is THE place on the internet for free information and advice about wood stoves, pellet stoves and other energy saving equipment.

We strive to provide opinions, articles, discussions and history related to Hearth Products and in a more general sense, energy issues.

We promote the EFFICIENT, RESPONSIBLE, CLEAN and SAFE use of all fuels, whether renewable or fossil.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

BrianH

New Member

I have the exact same furnace in west central Indiana. You need to turn your C6 and C7 settings down. What kind of exhaust are you running?

BrianH

New Member

Sorry, skimmed past your chimney set up. You're more than likely pulling plenty of draft and all the draft fan is doing is getting in the way. I currently have my C6 setting at 125 and C7 setting at 350. May tweak it a little from there as it gets cold again this weekend, but through the cold snap last week, I was running 0.75 lbs/hr on level 1 and 4.0 lbs/hr on level 5. Draft fan and agitator on auto. Bottom air slide door 1.5" out. Pulling 600+ degree door temps.

BrianH

New Member

Also, you'll want to copy this, print it off, and keep it with your notes...

C- 1 - Reset to defaults (hold Mode and Auger Delay buttons for 3 seconds to reset all to defaults)

C- 2 - Fuel Lbs Per Hour HR 1 (0-20.00) - This is the fuel rate in pounds per hour for a heat range setting of 1. The default is 5.00lbs.

C- 3 - Fuel Lbs Per Hour HR 9 (0-20.00) - This is the fuel rate in pounds per hour for a heat range setting of 9. The default is 13.lbs. The fuel rates used between settings 1 and 9 are linearly interpolated between these two settings.

C- 4 - Agitator On Percentage HR 1 (0-100) - This is the Percent On time for the agitator for a setting of 1. The default is 25%.

C- 5 - Agitator On Percentage HR 9 (0-100) - This is the Percent On time for the agitator for a setting of 9. The default is 50%. The percent on time for the agitator used between settings 1 and 9 are linearly interpolated between these two

settings.

C- 6 - Draft Fan Level HR 1 (0-500) - This is the Draft fan output level for a draft fan setting of 1. The default is 150/500.

C- 7 - Draft Fan Level HR 9 (0-500) - This is the Draft fan output level for a draft fan setting of 9. The default is 400/500.

C- 8 – Fuel Rate Type Compensation (50%-200%) – This parameter affects how much the auger runs to produce a given fuel rate. The default fuel rates are based on corn. This is the default setting for this parameter, or 100%. If the parameter is adjusted up, the auger rate is increased proportionally. If the fuel being used is less dense than corn (wood pellets for instance), it may be necessary to raise this parameter to compensate. This makes the programmed lbs per hour correspond to the particular fuel type. Typically, wood pellets need to be run at 120% toc ompensate for their lower density and slower travel through the auger system.

C- 9 - Ramp Seconds for Increasing Level (0-300) - When the heat range setting is adjusted, the control will ramp from the current setting to the target setting to avoid abrupt changes in the outputs that could cause problems with the flame quality. The Ramp Seconds value sets the amount of time to spend on each heat range setting (1-9 pseudo ranges not 1-5 user ranges) as the current setting is ramping toward the target. If the current setting is ramping down toward a lower target, the ramp value is half this number. The default value is 120 seconds.

C-10 - Startup Minutes for Detecting Warm Furnace - (10-60) This is the amount of time the control will wait for the furnace to reach the warm temperature (110 Degrees F) after the furnace has been started before shutting down and reporting an Error condition Err3. The default is 30 minutes.

C-11 – Overtemp Setpoint - (0-700) This is the measured flue gas temperature that will cause an overtemp condition. In this condition, the control will stop augering fuel until the temperature returns to a safe operating point. The default is 575 degrees F.

C-12 – Cutback Setpoint - (0-700) This is the measured flue gas temperature that will cause a cutback condition. In this condition, the control will ramp the heat range down based on the ramp seconds described above divided by 2 until the

temperature falls below the cutback setpoint. The default is 550 degrees F.

C-13 – Room Fan On Setpoint - (0-700) This is the temperature that the measured flue gas can reach before a the flue controlled foom fan turns on. If the measured temperature is higher than this setpoint, the control will turn on the flue controlled room fan. This variable also serves to indicate to the control that the stove is warm. If the measured temperature is higher than this setpoint, the stove is considered warm and will not create an Er 3. Whether or not the stove is warm also determines if the unit will recover from a power failure. If the stove is warm when power is lost and cold when it returns, it will shutdown with an Er 4 error.

The default is 200 degrees F.

C-14 – Cold Stove Setpoint - (0-700) This variable is used to determine when the furnace is cold and ready to be shut down. If during the shutdown sequence the measured temperature is less than this value, the furnace will stop running the

fans to cool it off. The default is 120 degrees.

C-15 – Low Temp Vent Heatrange – (0-9) This variable is used to control the vent controlled room fan. If the pseudo heat range (1-9) is greater than this number, the vent controlled room fan will turn on. If the pseudo heat range is less

than this number, the vent controlled room fan will turn off. The default for this parameter is 3.

C-16 – High Temp Vent Setpoint – (70-400) This variable is used to limit the maximum vent temperature. If the measured vent temperature is greater than the High Temp Vent Setpoint, the furnace will reduce the heat range by 1. If the vent temperature falls below the setpoint – 5, the heat range will ramp back to normal. The default for this setpoint is 225 degrees.

C-17 – Auger Period in Seconds – (5-20) This is the fixed auger period. The on time is calculated based on the setpoint fuel rate in lbs and the full on rate set in. The default is 10.00 Seconds.

C-18 – Full On Fuel Rate in Lbs/Hour – (7-40) This is the fuel rate that would be delivered if the auger was turned 100% of the time. This definition is for corn only (see proportional offset parameter CCool. The default value for this parameter is 36 lbs of corn per hour.

C-19 – Ignore Sense Errors (0-1) When this parameter is set to 1, the sensor errors including Interlock, and all fuse detection errors are disabled. The default is 0 (sense errors enabled).

C-20 – Ignore Vacuum Switch (0-1) When this parameter is set to 1, the vacuum switch is ignored. The default is 0 (do not ignore the vacuum switch).

C-21 – Bump Rate in Lbs (0-0.5) When the furnace is in shutdown, this parameter

can be used to force a small amount of fuel to be pushed through the auger to keep the fuel in the auger from getting hot. The default is 0lbs per hour.

C-22 – Purge Seconds (0-120) After shutdown, the auger can be run for a fixed amount of time to dump any fuel that may have become hot in the auger. By default, the auger will run in this purge mode for 30 seconds after shutting down.

C- 1 - Reset to defaults (hold Mode and Auger Delay buttons for 3 seconds to reset all to defaults)

C- 2 - Fuel Lbs Per Hour HR 1 (0-20.00) - This is the fuel rate in pounds per hour for a heat range setting of 1. The default is 5.00lbs.

C- 3 - Fuel Lbs Per Hour HR 9 (0-20.00) - This is the fuel rate in pounds per hour for a heat range setting of 9. The default is 13.lbs. The fuel rates used between settings 1 and 9 are linearly interpolated between these two settings.

C- 4 - Agitator On Percentage HR 1 (0-100) - This is the Percent On time for the agitator for a setting of 1. The default is 25%.

C- 5 - Agitator On Percentage HR 9 (0-100) - This is the Percent On time for the agitator for a setting of 9. The default is 50%. The percent on time for the agitator used between settings 1 and 9 are linearly interpolated between these two

settings.

C- 6 - Draft Fan Level HR 1 (0-500) - This is the Draft fan output level for a draft fan setting of 1. The default is 150/500.

C- 7 - Draft Fan Level HR 9 (0-500) - This is the Draft fan output level for a draft fan setting of 9. The default is 400/500.

C- 8 – Fuel Rate Type Compensation (50%-200%) – This parameter affects how much the auger runs to produce a given fuel rate. The default fuel rates are based on corn. This is the default setting for this parameter, or 100%. If the parameter is adjusted up, the auger rate is increased proportionally. If the fuel being used is less dense than corn (wood pellets for instance), it may be necessary to raise this parameter to compensate. This makes the programmed lbs per hour correspond to the particular fuel type. Typically, wood pellets need to be run at 120% toc ompensate for their lower density and slower travel through the auger system.

C- 9 - Ramp Seconds for Increasing Level (0-300) - When the heat range setting is adjusted, the control will ramp from the current setting to the target setting to avoid abrupt changes in the outputs that could cause problems with the flame quality. The Ramp Seconds value sets the amount of time to spend on each heat range setting (1-9 pseudo ranges not 1-5 user ranges) as the current setting is ramping toward the target. If the current setting is ramping down toward a lower target, the ramp value is half this number. The default value is 120 seconds.

C-10 - Startup Minutes for Detecting Warm Furnace - (10-60) This is the amount of time the control will wait for the furnace to reach the warm temperature (110 Degrees F) after the furnace has been started before shutting down and reporting an Error condition Err3. The default is 30 minutes.

C-11 – Overtemp Setpoint - (0-700) This is the measured flue gas temperature that will cause an overtemp condition. In this condition, the control will stop augering fuel until the temperature returns to a safe operating point. The default is 575 degrees F.

C-12 – Cutback Setpoint - (0-700) This is the measured flue gas temperature that will cause a cutback condition. In this condition, the control will ramp the heat range down based on the ramp seconds described above divided by 2 until the

temperature falls below the cutback setpoint. The default is 550 degrees F.

C-13 – Room Fan On Setpoint - (0-700) This is the temperature that the measured flue gas can reach before a the flue controlled foom fan turns on. If the measured temperature is higher than this setpoint, the control will turn on the flue controlled room fan. This variable also serves to indicate to the control that the stove is warm. If the measured temperature is higher than this setpoint, the stove is considered warm and will not create an Er 3. Whether or not the stove is warm also determines if the unit will recover from a power failure. If the stove is warm when power is lost and cold when it returns, it will shutdown with an Er 4 error.

The default is 200 degrees F.

C-14 – Cold Stove Setpoint - (0-700) This variable is used to determine when the furnace is cold and ready to be shut down. If during the shutdown sequence the measured temperature is less than this value, the furnace will stop running the

fans to cool it off. The default is 120 degrees.

C-15 – Low Temp Vent Heatrange – (0-9) This variable is used to control the vent controlled room fan. If the pseudo heat range (1-9) is greater than this number, the vent controlled room fan will turn on. If the pseudo heat range is less

than this number, the vent controlled room fan will turn off. The default for this parameter is 3.

C-16 – High Temp Vent Setpoint – (70-400) This variable is used to limit the maximum vent temperature. If the measured vent temperature is greater than the High Temp Vent Setpoint, the furnace will reduce the heat range by 1. If the vent temperature falls below the setpoint – 5, the heat range will ramp back to normal. The default for this setpoint is 225 degrees.

C-17 – Auger Period in Seconds – (5-20) This is the fixed auger period. The on time is calculated based on the setpoint fuel rate in lbs and the full on rate set in. The default is 10.00 Seconds.

C-18 – Full On Fuel Rate in Lbs/Hour – (7-40) This is the fuel rate that would be delivered if the auger was turned 100% of the time. This definition is for corn only (see proportional offset parameter CCool. The default value for this parameter is 36 lbs of corn per hour.

C-19 – Ignore Sense Errors (0-1) When this parameter is set to 1, the sensor errors including Interlock, and all fuse detection errors are disabled. The default is 0 (sense errors enabled).

C-20 – Ignore Vacuum Switch (0-1) When this parameter is set to 1, the vacuum switch is ignored. The default is 0 (do not ignore the vacuum switch).

C-21 – Bump Rate in Lbs (0-0.5) When the furnace is in shutdown, this parameter

can be used to force a small amount of fuel to be pushed through the auger to keep the fuel in the auger from getting hot. The default is 0lbs per hour.

C-22 – Purge Seconds (0-120) After shutdown, the auger can be run for a fixed amount of time to dump any fuel that may have become hot in the auger. By default, the auger will run in this purge mode for 30 seconds after shutting down.

Hey Brian. I've been to Clinton before, nice place, I'm down in Holland area about 2- 2.5 hours south. Thanks for taking the time to read my post. That's almost unbelievable running .75lb/hr on HR1 and only 4lb/hr on HR5 pulling 600 deg on door. I've tweaked around with them there C6 and C7 settings but I was going the wrong direction with them so I'll have to try setting them like you have give it a couple hours see where it goes and fine tune from there. It has been in upper 50's to low 60's this week (68 today) and I burned 5 bags thinking to myself something ain't right cause at that rate I'll go through 6 ton this winter if not more. Does your flame burn steady on those settings to top of burn chamber or steady just a couple inches above burn pot? Last year my father in-law installed this stove and it burned on manual all winter so this year it's a new learning curve using the thermostat and running auto mode but with your help and help from others like you we'll get there and maybe help someone else along the way. Thank you. I'll certainly print off the settings directions you included and keep that with the rest of my records and paper work that go along with stove. ThanksAlso, you'll want to copy this, print it off, and keep it with your notes...

C- 1 - Reset to defaults (hold Mode and Auger Delay buttons for 3 seconds to reset all to defaults)

C- 2 - Fuel Lbs Per Hour HR 1 (0-20.00) - This is the fuel rate in pounds per hour for a heat range setting of 1. The default is 5.00lbs.

C- 3 - Fuel Lbs Per Hour HR 9 (0-20.00) - This is the fuel rate in pounds per hour for a heat range setting of 9. The default is 13.lbs. The fuel rates used between settings 1 and 9 are linearly interpolated between these two settings.

C- 4 - Agitator On Percentage HR 1 (0-100) - This is the Percent On time for the agitator for a setting of 1. The default is 25%.

C- 5 - Agitator On Percentage HR 9 (0-100) - This is the Percent On time for the agitator for a setting of 9. The default is 50%. The percent on time for the agitator used between settings 1 and 9 are linearly interpolated between these two

settings.

C- 6 - Draft Fan Level HR 1 (0-500) - This is the Draft fan output level for a draft fan setting of 1. The default is 150/500.

C- 7 - Draft Fan Level HR 9 (0-500) - This is the Draft fan output level for a draft fan setting of 9. The default is 400/500.

C- 8 – Fuel Rate Type Compensation (50%-200%) – This parameter affects how much the auger runs to produce a given fuel rate. The default fuel rates are based on corn. This is the default setting for this parameter, or 100%. If the parameter is adjusted up, the auger rate is increased proportionally. If the fuel being used is less dense than corn (wood pellets for instance), it may be necessary to raise this parameter to compensate. This makes the programmed lbs per hour correspond to the particular fuel type. Typically, wood pellets need to be run at 120% toc ompensate for their lower density and slower travel through the auger system.

C- 9 - Ramp Seconds for Increasing Level (0-300) - When the heat range setting is adjusted, the control will ramp from the current setting to the target setting to avoid abrupt changes in the outputs that could cause problems with the flame quality. The Ramp Seconds value sets the amount of time to spend on each heat range setting (1-9 pseudo ranges not 1-5 user ranges) as the current setting is ramping toward the target. If the current setting is ramping down toward a lower target, the ramp value is half this number. The default value is 120 seconds.

C-10 - Startup Minutes for Detecting Warm Furnace - (10-60) This is the amount of time the control will wait for the furnace to reach the warm temperature (110 Degrees F) after the furnace has been started before shutting down and reporting an Error condition Err3. The default is 30 minutes.

C-11 – Overtemp Setpoint - (0-700) This is the measured flue gas temperature that will cause an overtemp condition. In this condition, the control will stop augering fuel until the temperature returns to a safe operating point. The default is 575 degrees F.

C-12 – Cutback Setpoint - (0-700) This is the measured flue gas temperature that will cause a cutback condition. In this condition, the control will ramp the heat range down based on the ramp seconds described above divided by 2 until the

temperature falls below the cutback setpoint. The default is 550 degrees F.

C-13 – Room Fan On Setpoint - (0-700) This is the temperature that the measured flue gas can reach before a the flue controlled foom fan turns on. If the measured temperature is higher than this setpoint, the control will turn on the flue controlled room fan. This variable also serves to indicate to the control that the stove is warm. If the measured temperature is higher than this setpoint, the stove is considered warm and will not create an Er 3. Whether or not the stove is warm also determines if the unit will recover from a power failure. If the stove is warm when power is lost and cold when it returns, it will shutdown with an Er 4 error.

The default is 200 degrees F.

C-14 – Cold Stove Setpoint - (0-700) This variable is used to determine when the furnace is cold and ready to be shut down. If during the shutdown sequence the measured temperature is less than this value, the furnace will stop running the

fans to cool it off. The default is 120 degrees.

C-15 – Low Temp Vent Heatrange – (0-9) This variable is used to control the vent controlled room fan. If the pseudo heat range (1-9) is greater than this number, the vent controlled room fan will turn on. If the pseudo heat range is less

than this number, the vent controlled room fan will turn off. The default for this parameter is 3.

C-16 – High Temp Vent Setpoint – (70-400) This variable is used to limit the maximum vent temperature. If the measured vent temperature is greater than the High Temp Vent Setpoint, the furnace will reduce the heat range by 1. If the vent temperature falls below the setpoint – 5, the heat range will ramp back to normal. The default for this setpoint is 225 degrees.

C-17 – Auger Period in Seconds – (5-20) This is the fixed auger period. The on time is calculated based on the setpoint fuel rate in lbs and the full on rate set in. The default is 10.00 Seconds.

C-18 – Full On Fuel Rate in Lbs/Hour – (7-40) This is the fuel rate that would be delivered if the auger was turned 100% of the time. This definition is for corn only (see proportional offset parameter CCool. The default value for this parameter is 36 lbs of corn per hour.

C-19 – Ignore Sense Errors (0-1) When this parameter is set to 1, the sensor errors including Interlock, and all fuse detection errors are disabled. The default is 0 (sense errors enabled).

C-20 – Ignore Vacuum Switch (0-1) When this parameter is set to 1, the vacuum switch is ignored. The default is 0 (do not ignore the vacuum switch).

C-21 – Bump Rate in Lbs (0-0.5) When the furnace is in shutdown, this parameter

can be used to force a small amount of fuel to be pushed through the auger to keep the fuel in the auger from getting hot. The default is 0lbs per hour.

C-22 – Purge Seconds (0-120) After shutdown, the auger can be run for a fixed amount of time to dump any fuel that may have become hot in the auger. By default, the auger will run in this purge mode for 30 seconds after shutting down.

BrianH

New Member

5 bags is a ton. It takes me 2+ days to go through that even on level 5. I get massive flames that go up to the heat exchanger grill in the top. I've had mine shut down for the last 2 days because it's been too warm for it. Even at just a pilot light level at 0.75 lbs/hr, it gets the house to 85+ degrees. I left all other settings at default, but C6 and C7 have to come down to keep the draft fan from doing its 1 second on/1 second off deal consistently. Your chimney will do the drafting itself just fine. The draft fan really only comes into play with short, horizontal vents, once you set up an actual chimney that will pull a draft, the fan just gets in the way and causes problems. I've had mine for about 5 years now but it took me a season to figure out why I was going through so many pellets. Finally went back to my knowledge of log burners and did away with the draft fan almost entirely and it produces more heat at 4 lbs/hr than it was at 7/hr before. Draft can make or break a wood burning appliance.

BrianH

New Member

You did pull the little black jumper from between the t-stat leads, didn't you? Just checking. The way it works on thermostat is when it's not calling for heat, it'll go to level 1 and sit there to keep the stove going until it's ready for heat again, then when it calls for heat it'll ramp up to whatever you have the control panel set on, so if you find that level 4 is sufficient to heat your house, then put control panel on PR-4 and it'll ramp to 4 and then go back to 1 when it stops calling for heat. I set my level 5 for between 625-650ish degrees on the hottest part of the door and usually run on level 4 in the cold times. My method of pulling heat out of my furnace is to set the furnace on level 3, open the air door 1.5" out, then adjust the exhaust fan down from factory until I start losing heat on the door, then go up until I start losing heat again, then back it off to the setting that gave me the hottest door temp on my Lazer thermometer, then set my high pellet rate to match the temp I want it to be in the house on the coldest day of the year. Sometimes I have to guess at that number but if it starts getting cold in the house, I can bump up the feed rate a little until I find the correct top end rate. Also, try to get your return air from the warm part of the house back to the furnace. I built a return air box out of some 1x2 hardwood boards and some aluminum trim coil with a 12" flexible duct from a $20 filter box from Lowe's to the return air box. That makes a huge difference in temperature of the air coming back to the house.

yeah I thought 5 bags when highs are in low 60's and lows of about 45-50 was a bit overboard and when it ramped down to HR1 you could barely see a flame every other second. Where my 3inch exhaust pipe goes into chimney there was about 1/4 to 1/2 inch gap around pipe and when I put my hand up to that gap I could actually feel it pulling air so I took some of that chimney sealant (basically high temp silicone) and a piece of the high temp gasket rope than wrapped it around the gap and sealed it off hoping that would save the day but nothing although I'm sure it didn't hurt anything. For this evening the unit is powered down but tomorrow I'll turn it back on do some adjustments and hope for happy pellet burning. I'll let you know how it turns out and if you think of anything else let me know. Thank you5 bags is a ton. It takes me 2+ days to go through that even on level 5. I get massive flames that go up to the heat exchanger grill in the top. I've had mine shut down for the last 2 days because it's been too warm for it. Even at just a pilot light level at 0.75 lbs/hr, it gets the house to 85+ degrees. I left all other settings at default, but C6 and C7 have to come down to keep the draft fan from doing its 1 second on/1 second off deal consistently. Your chimney will do the drafting itself just fine. The draft fan really only comes into play with short, horizontal vents, once you set up an actual chimney that will pull a draft, the fan just gets in the way and causes problems. I've had mine for about 5 years now but it took me a season to figure out why I was going through so many pellets. Finally went back to my knowledge of log burners and did away with the draft fan almost entirely and it produces more heat at 4 lbs/hr than it was at 7/hr before. Draft can make or break a wood burning appliance.

85 degrees at .75lbs/hr wow! I did pull little black jumper when I hooked thermostat to it and noticed how when calls for heat it goes up to where it's set (I had it on HR3 for now) than when satisfied it goes back to HR1 but I lost about all the heat(would hover around 100) on hot part of door so when it called for heat again it felt like it took forever to get there since it cooled off so much so quick. I have the intake for room fans hooked to cold air return in the same place where it used to have a log burner (from 1983 up to 2011) hooked up but would like to get more air to room fans cause they seem to be starving so that may be a good time to add an independent cold air return vent in warmest part of house. I really like how the rooms fans are always on circulating air than it don't get so stuffy and surely has huge gain on efficiency than when calls for heat the room fans ramp up. I think tomorrow before I fire it up I'll do a complete reset back to defaults and set it the way you described as it seems to be working great for you. Thanks for the help

BrianH

New Member

You're welcome. Do you have your small door on the side under the control panel removed to boost the air coming out of the stove? I found that is a definite must. It shouldn't take that long to ramp from 1 to 3. Even at a very low setting for 1. I think once you get the combustion air dialed in, you'll see a big difference in heat output and ramp time.

I did remove the small door under control panel but decided to put it back on till I devised a system to get a filter installed for that air. In manual it says the room blowers move 1600 (800 each) CFM of air and right away once both fans got going you could tell it was craving more air than it was getting from the 10X20X1 filter area in back. Since you said something about hooking it up to warmest place in house I'll try to dedicate that part (under control panel) to independent return vent. Other than not getting enough air for room fans and not having combustion air dialed in I really really like the 8500 and certain it will heat house for way less than my 12 year old heat pump. The forecast must of changed when cold front coming through so we got 58 degrees now but will do some tuning in and tweaking on stove to get it burning good. Thank you for the assistance and let me know if you know of anything else. ThanksYou're welcome. Do you have your small door on the side under the control panel removed to boost the air coming out of the stove? I found that is a definite must. It shouldn't take that long to ramp from 1 to 3. Even at a very low setting for 1. I think once you get the combustion air dialed in, you'll see a big difference in heat output and ramp time.

BrianH

New Member

I will do. Having that secondary panel open made a world of difference for me. I just built a box frame across the back of the unit in an L shape to cover that little door also. It's about 32" wide, 14" deep, and 13" tall and covers the entire back end where the fans sit and across the little door on the side. I then covered the frame in aluminum trim coil, stapled it to the wood frame and ran foil tape across all seams. When I get home I'll try to snap a pic of it and show you. Mine is in a shed I built right off the house, so I ran a 12" flexible duct from the wall of the house to the shed for the return air, then just framed a 14x25 filter frame into the wall inside with a 12" start collar through the wall. It seems to supply plenty of air back to the furnace and my register temps increased by 30 degrees. If I find anything else I might have overlooked that makes it burn more efficiently, I'll let you know, but I know my chimney system pulls a good steady draft with the fan all but off. I'm running a 3" double wall stainless 1' through a sidewall to a clean out T, then vertical 7' to a 90 and then a 45 turn down cap. It pulls really strong, but if you get your fan setting correct at a specific air door setting, you can adjust the amount of draft with that slide door from there.

jzm2cc

Minister of Fire

When you have time look on YouTube under 8500 furnace. Excellent video's done by "Land Air Mechanical" I believe. He shows how to get maximum efficiency out of these units.

BrianH

New Member

I started with his videos also. His settings were what I ran off of for a while, but with my chimney set up, the draft fan was running far too much and my chimney temps right off the stove were getting close to 200 degrees while my door temps never went over 500. Every chimney is going to provide a different draft, so it has to be set on a case by case scenario. The heat adjustment procedure I laid out has been the most effective method I've found of dialing the furnace in. He has great videos and I learned a ton from them, but when it comes to setting draft fan and air settings, his exact settings won't work for every chimney. The OP will wind up with different settings than I have too, I can almost guarantee that. That's why I laid out how I get the most efficiency out of my particular furnace/chimney set up. So he could do the same and get it dialed in perfect for his set up.

BrianH

New Member

Fired mine up again tonight. HR1 still at 0.75, HR 5 at 5.5. Set on level 4 I'm pulling 540 degrees on the door, 120 degrees on the exhaust right off the furnace, 92 degrees on the bonnet where the air comes in the house. 89 degrees coming out of the vents. C7 set on 100, C8 set on 300.

Before I fired unit up tonight I gave it a good cleaning and read these posts again and again than studied the C settings page again and againFired mine up again tonight. HR1 still at 0.75, HR 5 at 5.5. Set on level 4 I'm pulling 540 degrees on the door, 120 degrees on the exhaust right off the furnace, 92 degrees on the bonnet where the air comes in the house. 89 degrees coming out of the vents. C7 set on 100, C8 set on 300.

BrianH

New Member

I meant C6 at 100 and C7 at 300, btw. Did you fire it up last night? If so, how did it do? I'll take some pictures later for you of that return air I built. Coffee first.

oops got a little to happy with the post button. After I gave it a cleaning I fired it up and set C6 to 175 and C7 to 350. I have it on Pr3 and I let it run for about 45 minutes and the flame was about dead. I pushed manual button and salvaged what little flame was left. I set HR1 to 2lbs/hr and HR5 to 5lbs/hr and looked at C setting paper again and thought well these settings have parameters and the unit has overtemp protection built in so I ran C7 to high end of parameter(500) than dropped C6 to100 and almost instantly door temp started going up (about 400) and the flame was dancing with some rhythm up to heat exchanger holes. I did not get the cold air return hooked to small panel on bottom corner yet (ran out of time) but certain that will make a huge difference and keep the thermostat happier longer. I have watched all the land/air videos and he is very smart and knows what's going on and I started out using the settings he used but much like you said those settings don't work for every situation (even though there both inline sixes you can't put a 3406 Cat crank in a Ford 300). My draft fan still surges but since I've tweaked the C6 and C7 settings the flame looks better and door gets hotter even with the surging. My door is white as it got overtemped last winter so now I'm asking myself did a sensor get goofed due to that? I've got pics of my setup and if I don't forget I'll post them. Thanks

BrianH

New Member

Making progress. It'll take some time, but you'll get dialed in. Just remember, you don't want to run the fan so hard it pulls heat out of the box unnecessarily. Slowly move the C6 & 7 settings until you get your highest door temps and you'll be set.

BrianH

New Member

Here's the return air box I built. It's pretty simplistic, but it works. You can see the 12" flexible duct running back to the house coming off the box in the second picture.

BrianH

New Member

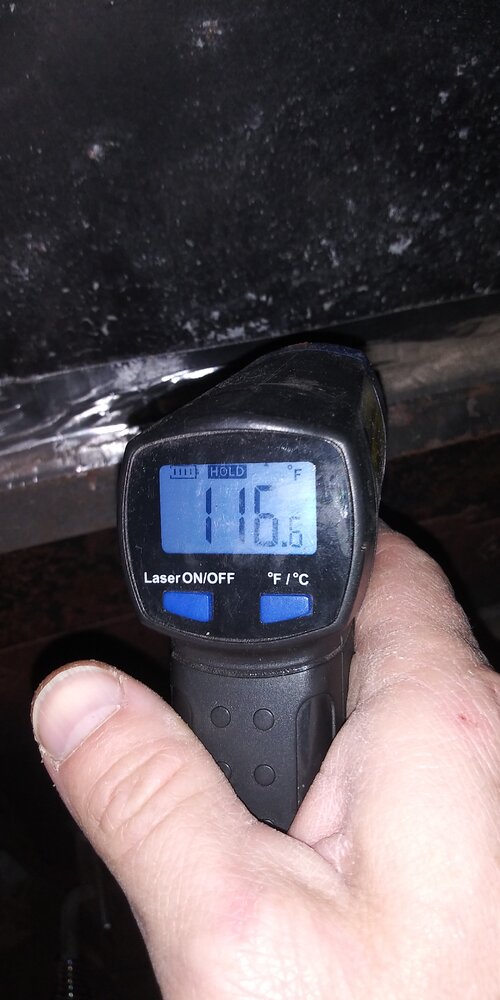

These are the temps my furnace is running right now on level 4 after running all night. First is door temp in the middle of the door, second is exhaust temp right off the furnace, and the third is the bonnet temp of the air coming into the house. This way you can see what kind of temps these are capable of putting out. With C8 setting at 110, HR1 AT 0.75 AND HR5 at 5.9. I did some number crunching last night and found out at HR4, I should be able to get 36 hours of burn time out of a full load in the stove if I have the C8 setting correct and it's actually using 5.9 lbs/hr on HR5. There really aren't any threads showing how to dial these furnaces in out there so I'll be continually updating this thread as I dial it in so others can see the process. Currently, I'm running my C7 & 8 settings down by 10 to see what the temps do with each adjustment.

A lot to follow and read there, and I'm not familiar with this stove and settings, but. Did you install an outside air kit, I realize you mentioned your in a leaky basement, and use a cold air return but these pellet stoves have forced exhaust and move a ton of air volume, it would be better to not draw in cold air from every leak in the house and use heated air to burn in the combustion and send back out the chimney, thats a lot of air to replace and it gotta come from outside, thats why a OAK is usually advised.

BrianH

New Member

Sound advice on the cold air kit. I don't have a new one built for mine since it's in a new location this year, but taking advantage of the fairly warm temps we have right now to dial it in, then I will be putting a cold air kit on mine. Though, mine isn't in my house, it's in a shed right outside the house. Still, 650 degree door temps go a long way in an 8x10 shed in terms of warmth.

Update on my progress. Don't adjust more than 10 notches at a time on the fan settings. I did and wound up going too low too fast and had 670 degree door temps on level 4. Currently running it with everything wide open to cool it down and get rid of the packed full burn basket.

Update on my progress. Don't adjust more than 10 notches at a time on the fan settings. I did and wound up going too low too fast and had 670 degree door temps on level 4. Currently running it with everything wide open to cool it down and get rid of the packed full burn basket.

I hope you have gotten stove cooled back down!! You weren't kidding around when you said your cold air return kit is simple. Sometimes, most of the time, the simplest ways are the best ways but for this control panel programming business not so much for me anyway. I'd make one (and would make one) like that but father in-law had one made up for back of unit (10x20x1 filter area) already so I felt it'd be best to use it and make up a separate one for under control panel (it'll look similar to the one the Land Air mechanical guy has on his in the videos). I got some duct work earlier today to make that happen than likely a whole new thing for programming. I fired up unit last night as I said earlier messed with C6 and C7 filled the hopper to top and away we went. This morning the house was a comfortable 70deg but burned probably 20lbs (just a guess without actually weighing) with HR1 to 2lbs/hr and HR5 to 5lbs/hr but temps last night only bottomed out around 37-40deg. The thermostat wasn't calling for heat this morning when I checked unit so it was defaulted back to HR1 and door was only 100deg. I did not check door temp in middle of night. My chimney has two flues (about 6-8 inches between them at top) and I thought it would be extremely easy for me to hook Outside Air Kit to second flue since it ain't being used for anything using the whole cold air goes down science to my advantage but I'm afraid to do that cause it might actually start a suction at top and pull exhaust/smoke (other flue where unit exhausts) back down and try to burn it. I can get outside cold air for combustion to unit thru a different path but just takes a few more feet of pipe and an extra elbow. Providing I did it right I attached some photos of how unit is hooked up now until I get other cold air return hooked up under control panel.Sound advice on the cold air kit. I don't have a new one built for mine since it's in a new location this year, but taking advantage of the fairly warm temps we have right now to dial it in, then I will be putting a cold air kit on mine. Though, mine isn't in my house, it's in a shed right outside the house. Still, 650 degree door temps go a long way in an 8x10 shed in terms of warmth.

Update on my progress. Don't adjust more than 10 notches at a time on the fan settings. I did and wound up going too low too fast and had 670 degree door temps on level 4. Currently running it with everything wide open to cool it down and get rid of the packed full burn basket.

Attachments

BrianH

New Member

Sounds like you may need to adjust your C6 setting up some if you're having better luck with the higher setting on C7. That should bring your door temps up around 300 range when you find your C6 setting.

Similar threads

- Replies

- 2

- Views

- 262

- Replies

- 2

- Views

- 287

- Replies

- 1

- Views

- 2K

- Replies

- 9

- Views

- 1K

![Photo0727[1].jpg](/talk/data/attachments/269/269262-2b49e1755d553a410523def1e8bce5a7.jpg)

![Photo0728[1].jpg](/talk/data/attachments/269/269263-c5c45fc13e3f2d08983c59b01564b5b0.jpg)

![Photo0729[1].jpg](/talk/data/attachments/269/269264-e854cbbbe109d6f2545369e07bfc3e14.jpg)

![Photo0730[1].jpg](/talk/data/attachments/269/269265-c98b61bafaebc4301683d6529ee9cd17.jpg)

![Photo0731[1].jpg](/talk/data/attachments/269/269266-b516db8e9d8972cff9f43d632ad55ee5.jpg)

![Photo0732[1].jpg](/talk/data/attachments/269/269267-747cdc646cba27fdfd877fe829d33080.jpg)