I have been reading about storage fo 2 weeks but can't find the info I need. I have read and fully understand how the simplest storage sticky would operate but that system will not work on my system due to the fact that the load circuit must run at all times so if the house calls for heat the air handler has hot water to work with.

A little info on my system. I have a econoburn 200 that is plumbed with a primary and secondary with 1 inch copper and 1" A PEX. Water runs 400 ft round trip to my house and back to my shop through 2 heat exchangers. It works great and I Have no trouble heating my house and shop wich is over 3000 sq ft. My hope is just like most of us is to have fewer and more intense fires. I have read alot on storage but have found more opinion than fact, more technical wording than real solutions. I know and can appreciate the mathmatical formulas that could help build the perfect system but would like to keep it simple. My system works fine and all I want to do is ad some volume to slow the swing of temps and maybe allow myself some extra time between burns.

First major issue I found is the fact that as great as my econoburn is it isn't smart enough to relize it is out of wood and will continue to run.

Fortunatly I work out of my shop and can monitor my stove at most times.

I would like to see a plumbing design specifically for a system that requires constant flow on the load circuit.

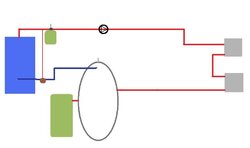

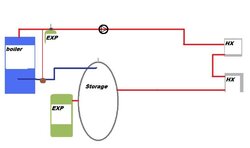

After alot of thinking and reading I feel the best situation for a system that requires constant flow is a storage tank that is plumed in series with the return line after the loads. When the stove is running it is pumping water through the loads wich will take heat if needed and then the water flows thorugh the storage , the storage will soak up any excess btus , obviously more if the loads aren't using heat. the water will always cirulate as long as the water stays above 150 . and when I have my storage charged I can leave my stove on to contrrol the pump but I can use a simple switch on the fan cicuit to shut the draft fan completely off. I realize this isn't the perfect setup but I can't seem to see why it wouldn't work fine.

Please weigh in on this diagrahm and if u got a better idea please share with pics.

Also I want to remove the secondary loop pump from my system and replace it with a mixing valve for boiler protection. What kind of valve are you using that is automatic and works for this purpose.

A little info on my system. I have a econoburn 200 that is plumbed with a primary and secondary with 1 inch copper and 1" A PEX. Water runs 400 ft round trip to my house and back to my shop through 2 heat exchangers. It works great and I Have no trouble heating my house and shop wich is over 3000 sq ft. My hope is just like most of us is to have fewer and more intense fires. I have read alot on storage but have found more opinion than fact, more technical wording than real solutions. I know and can appreciate the mathmatical formulas that could help build the perfect system but would like to keep it simple. My system works fine and all I want to do is ad some volume to slow the swing of temps and maybe allow myself some extra time between burns.

First major issue I found is the fact that as great as my econoburn is it isn't smart enough to relize it is out of wood and will continue to run.

Fortunatly I work out of my shop and can monitor my stove at most times.

I would like to see a plumbing design specifically for a system that requires constant flow on the load circuit.

After alot of thinking and reading I feel the best situation for a system that requires constant flow is a storage tank that is plumed in series with the return line after the loads. When the stove is running it is pumping water through the loads wich will take heat if needed and then the water flows thorugh the storage , the storage will soak up any excess btus , obviously more if the loads aren't using heat. the water will always cirulate as long as the water stays above 150 . and when I have my storage charged I can leave my stove on to contrrol the pump but I can use a simple switch on the fan cicuit to shut the draft fan completely off. I realize this isn't the perfect setup but I can't seem to see why it wouldn't work fine.

Please weigh in on this diagrahm and if u got a better idea please share with pics.

Also I want to remove the secondary loop pump from my system and replace it with a mixing valve for boiler protection. What kind of valve are you using that is automatic and works for this purpose.