Correct. 18" is the minimum clearance for single-wall pipe. No harm in exceeding the minimum. Yes, check that the pipe and support box are plumb.

Cathedral Ceiling Support Box

- Thread starter 04HemiRam2500

- Start date

-

Active since 1995, Hearth.com is THE place on the internet for free information and advice about wood stoves, pellet stoves and other energy saving equipment.

We strive to provide opinions, articles, discussions and history related to Hearth Products and in a more general sense, energy issues.

We promote the EFFICIENT, RESPONSIBLE, CLEAN and SAFE use of all fuels, whether renewable or fossil.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

- Status

- Not open for further replies.

Okay thanks again for clarification you are right I did not notice that you were just talking ot the other poster and not me too. Thanks again will let you know how it goes!!

cableman

Minister of Fire

Sorry if i made the thread confusing  Once begreen posted the folded over sides i thought i screwed up

Once begreen posted the folded over sides i thought i screwed up  ! Good info thread though!

! Good info thread though!

wonder why the instructions dont say any thing about folding over the sides!

Once begreen posted the folded over sides i thought i screwed up

Once begreen posted the folded over sides i thought i screwed up  ! Good info thread though!

! Good info thread though! wonder why the instructions dont say any thing about folding over the sides!

I agree how hard would be it too put it in the instructions!! I messed up to with this thread I thought begreen was referring to me. Glad we got all of this cleared up for anyone else that may encounter this issue!! Thanks

Hey all going to install the flashing tomorrow. I wanted to check how to install it I need to pull up but not off shingles so that the flashing will slip under them I will add roof tar blackjack to the underside of the flashing. The shingles need to come to the half way point of the circular part of the flashing correct? Then, I nail the flashing down where it is exposed and apply the roof tar. The shingles that are on top of the flashing, do I nail them down with a nail on top of the shingles or do I squeeze roof tar under them to lay them down? Thanks all just want to make sure do the job correctly.

cableman

Minister of Fire

I would mark on top where its gonna sit, the shingle that would cover the bottom is the one that the flashing will sit on and the rest go on top. Might be hard to just bend shingles up if its colder out. I would say they should a least come to the mid part and the rest under. Black jack is good under the flashing if you can get it there, I didn't and just tarred around the top and sides of flashing where shingles meet. If you can bend a shingle up top and get a nail that would be great, or top nail and blackjack it. Are you folding over the support or cutting it flat to match pitch?

FWIW I only used a good silicone for sealing. M&G says nail the top and sides.

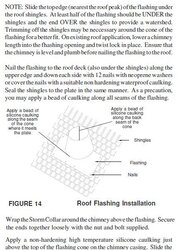

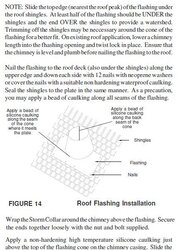

On an existing roof, center and install the Flashing before extending the chimney above the roof. Allow space to permit sliding the next Chimney Section up through the Flashing. Always insure the chimney remains vertical (use a level), and that at least a 2-inch clearance to combustible materials is maintained all around. Install the upper edge of the Flashing under the roofing. Nail to the roof along the upper edge and down each side with 1-inch roofing nails. Do not nail the lower edge of the Flashing (Fig 12). Be sure to follow local building practices, as needed. Seal all nail heads with a nonhardening waterproof sealant. On flat or tarred and graveled roofs, nail and seal the Flat Roof Flashing to the roof on all sides with roofing compound. Do not put screws through the Flashing into the Chimney Pipe.

And this is from Selkirk:

On an existing roof, center and install the Flashing before extending the chimney above the roof. Allow space to permit sliding the next Chimney Section up through the Flashing. Always insure the chimney remains vertical (use a level), and that at least a 2-inch clearance to combustible materials is maintained all around. Install the upper edge of the Flashing under the roofing. Nail to the roof along the upper edge and down each side with 1-inch roofing nails. Do not nail the lower edge of the Flashing (Fig 12). Be sure to follow local building practices, as needed. Seal all nail heads with a nonhardening waterproof sealant. On flat or tarred and graveled roofs, nail and seal the Flat Roof Flashing to the roof on all sides with roofing compound. Do not put screws through the Flashing into the Chimney Pipe.

And this is from Selkirk:

Last edited:

I have decided not to bring tthe square support box up through, instead I am going to cut a circle and leave the square box inside the roof. Will there be a problem with this? If you look at thee videeo below are the shingles on the roof down far enough on the flashing or should they go lower this is where I want to make sure I do it right. Now, for thee part of the flashing that is under the shingles do I send nails on top of the shingles through the flashing then put roof tar on top of that? thanks all.

cableman

Minister of Fire

I cut the hole using my bosche mutitool, you can cut from inside just through the plywood then cut the shingles to the round part of the flashing. Works well if ya have one like it. If you just cut the square frame out mount the box and stick a pipe length in and level it, mark the inner part where the shingle have to be cut around the flashing. Separate em with a spackle knife and slide it in place under the shingles! you can nail on top of shingles and cover with silicone. I used pl roof and flashing polly caulk! I love PL stuff!

In the directions with the pic that you posted begreen it says to nail the flashing under the shingles. How do you do that? Can you lift the shingles that high? Or do they mean nail it on top of the shingles?

Also, is it okay if I do not put the support box through the roof?

Also, is it okay if I do not put the support box through the roof?

cableman

Minister of Fire

The shingles may break if lifted too high in colder weather. The nail does only go just under the bottom edge of the tile being lifted. If you cant lift it i dont see a problem top nailing, just cover with sealant. If you didnt cut the box yet you could mark it after hole is cut or mark it when its level down below and cut back to whats needed to stick down and make it to the bottom of the flashing.

Okay but for the cathedral ceiling box, do I need to bring it through the roof or flush with the roof or can I just cut a circle in the roof?

cableman

Minister of Fire

I would bring it flush with the sheathing or close to it. I cut a square out the same size as the support box, the flashing covers it. Is yours framed square like the support box right to the roof?

Okay guys got it in today man that was an all day event. Here a a few questions. First off is it okay that I am at exactly two inch clearance? Please tell me the codes are not written more then 2 inch because there was a stud in the way. I did not bring the box up through instead since my cathedral ceiling is double studded I boxed it in on the top and bottom there are like 20 2 and 1/2 inch screws hold that sucker on. My first question is that I applied roof tar to the bottom and top of the storm collar. However, I noticed that from the inside you can move the chimney up and then down? Is this okay or did I miss something please please tell me know. Also, when I put the flashing in I noticed that there were three layers of shingles I got under all three but when I cut them, they were about 1/2 inch from being flush to the round part of the flashing. So, I just roof tared the gap. Lastly, I did what I though I would do, I did not leave room for the removal of the flue pipe. However, I can move the chimney u so is it okay to remove it like this or do I need to buy a telescoping piece of single wall pipe. However, the fit is designed to fit a 2 foot section perfectly? So maybe if I get two one foot sections there will be enough slack or no. My thinking is if it is okay to move the chimney pipe up I do not have to worry about the flue telescoping part? Also, when I went to lock the pipe adapter by turning it I ended up turning the whole chimney again will this mess up that tar around the storm collar I think yes?

My main concern is if I should lift the chimney to put the two foot section of stove pipe in or no just buy a telescoping part ist there one that size though

Thanks

Thanks

Sorry for rambling but am new at this!!

My main concern is if I should lift the chimney to put the two foot section of stove pipe in or no just buy a telescoping part ist there one that size though

Thanks

Thanks Sorry for rambling but am new at this!!

OK.

2" is the minimum, if you have that then no problems.

Roofing tar is fine between the flashing boot and the shingles, I prefer to leave a half inch gap and fill with tar, if you don't then leaves and crap get in there and cause problems later.

Roofing tar should not be on the chimney itself. It's flammable! And doesn't seal metal to metal well. You need to use Silicone instead.

Your chimney pipe should come through your flashing without sealant, the sealant goes between the storm collar and the pipe. You have a ventilated flashing right? So, if it was gonna leak under the storm collar, it would just come in the vent holes anyway.

You should shoot a few screws through the neck of the flashing and into the chimney's outer jacket so it cannot be lifted out. This bugs the heck outa me when I'm cleaning one! You will need a slip section of stove pipe, it will make your life so much easier!

It does seem to take a long time, but after a few hundred of them you'll get faster!

2" is the minimum, if you have that then no problems.

Roofing tar is fine between the flashing boot and the shingles, I prefer to leave a half inch gap and fill with tar, if you don't then leaves and crap get in there and cause problems later.

Roofing tar should not be on the chimney itself. It's flammable! And doesn't seal metal to metal well. You need to use Silicone instead.

Your chimney pipe should come through your flashing without sealant, the sealant goes between the storm collar and the pipe. You have a ventilated flashing right? So, if it was gonna leak under the storm collar, it would just come in the vent holes anyway.

You should shoot a few screws through the neck of the flashing and into the chimney's outer jacket so it cannot be lifted out. This bugs the heck outa me when I'm cleaning one! You will need a slip section of stove pipe, it will make your life so much easier!

It does seem to take a long time, but after a few hundred of them you'll get faster!

Is okay that roof tar is around the flashing now? Will I be able to remove it? Do they make a slip section the size of a two foot section? So, will the sealant directly hold the storm collar on the pipe?

Please let me know as soon as you can cause I did it at about 5 today and it is starting to get dark If I need to remove it now let me know!!

Also, I did roof tar around the circle part of the flashing and the vertical line that goes up the circle part of the flashing.

Please let me know as soon as you can cause I did it at about 5 today and it is starting to get dark If I need to remove it now let me know!!

Also, I did roof tar around the circle part of the flashing and the vertical line that goes up the circle part of the flashing.

That is where the the tar is to go. not around the storm collar. I wouldn't get up there now, but in the daylight pick it off and replace it with silicone.I did roof tar around the circle part of the flashing and the vertical line that goes up the circle part of the flashing.

Slip sections for single wall are 18". In Double wall they make telescoping kits as well as a short slip that goes in a standard piece of pipe, they are typically like 2-10" of adjustment.Do they make a slip section the size of a two foot section?

? I would use a putty knife and slowly "cut" it off. You could use a colored silicone so it will cover any left over tar. Just for looks.How easy is it to remove how do I do it?

I often put a sheet metal screw above the collar to hold it down, If it sits good and flat then the silicone will hold it just fine.

Good thing Is that it is on the backyard side of my house so looks do not concern me. But, Will ity come off easily with the putty knife? Also, what about any thin layers can I scrubb them off with a brillo pad or something or should I not worry about it. I was just concerned cause flammabe part. I

Okay, so are you just saying that the roof tar just should be removed because it does not stick well to the chimney pipe? Also, for the silicone caulking do I put a layer on top and bottom of flashing.

It is made for asphalt shingles, or metal to asphalt not metal to metal. And again, there isn't a need to use sealant between the pipe and the flashing, only between the collar and the pipe. Make sure to tool it, so many people put it on there with the gun and thats it! Don't be afraid to run your finger through it to make sure it's adhered good. It won't bite!

- Status

- Not open for further replies.

Similar threads

- Replies

- 2

- Views

- 318

- Replies

- 21

- Views

- 588

- Replies

- 8

- Views

- 495

- Replies

- 1

- Views

- 609