EdisonBurn

New Member

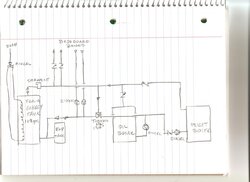

1. The DHW coil is a fairly large indirect coil like you would find in a boiler and is big enough to supply hot water for laundry and a shower simultaneously. But I take the output of the DHW coil through a Taco 5000 series mixing valve configured as a diverter valve where the output goes to the bottom of an electric water heater if it is below 135 degF and goes directly to the DHW demand if it is hot enough already. (I only heat up the main storage a little once in a while during the summer so there isn't necessarily wood heat for DHW all the time.)

2. Buffer tanks serve a few different purposes.

When I'm burning oil the buffer lets the oil burner run for longer stints so there's no short-cycling.

In my system the buffer serves four other purposes.

One is to make it simple and convenient to supply heat for all the loads regardless of where the heat is coming from. Any heat source can be on-line or off-line and the heat distribution works the same seamlessly.

Another is to separate cooler return water from hotter return water depending on the zone it's coming from. The cooler return water settles in the bottom of the buffer tank and the hotter water rises, so when the buffer is recharged the water returned to storage is the coolest possible, which increases the heat capacity of storage.

When heating from storage the buffer keeps the heated water for DHW and hot tub separate from the heated water for the baseboard and radiator loads.

And finally the buffer serves as a reservoir of 'spent' water from baseboard and radiator loads that is too cool for those loads but is plenty warm for the in-floor PEX circuits. This way the in-floor loads have an opportunity to lower the return temperature to storage even further, which helps to increase the heat capacity of storage even more.

(Here's a picture of my DIY buffer tank that many have seen plenty of times already.)

View attachment 150741

Thank you... awesome diagram and explanation.

! Waiting on SID to get the cad drawings of the tanks and I will go from their. I am not designing anything new...i'm coping standard ASME mech layouts. The hard part has already been done by a PE. Once you find the right design its like playing with legos.

! Waiting on SID to get the cad drawings of the tanks and I will go from their. I am not designing anything new...i'm coping standard ASME mech layouts. The hard part has already been done by a PE. Once you find the right design its like playing with legos.