It may be a little more complicated, but if you basically had a wye with the boiler on one leg, tank(s) on one and the load on one, then when the boiler is not warm it won't circulate through it. Of course this would cost some money in thermovar valves and t stats and whatnot.

Plumbing multiply storage tanks

- Thread starter NCFord

- Start date

-

Active since 1995, Hearth.com is THE place on the internet for free information and advice about wood stoves, pellet stoves and other energy saving equipment.

We strive to provide opinions, articles, discussions and history related to Hearth Products and in a more general sense, energy issues.

We promote the EFFICIENT, RESPONSIBLE, CLEAN and SAFE use of all fuels, whether renewable or fossil.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

- Status

- Not open for further replies.

maple1

Minister of Fire

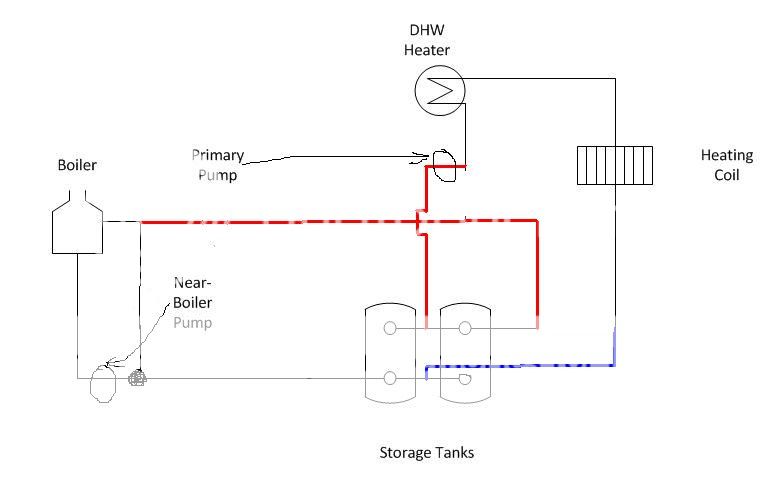

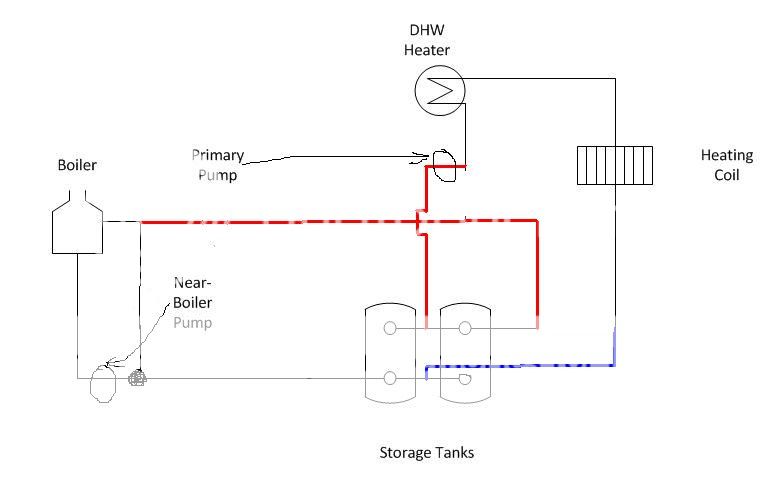

I took the liberty of butchering up Clarkbugs nice drawing:

I think to get the most out of your storage, you will need to draw from the top of it after the fire goes out. I just tried to show a way that might be able to be done. The primary could maybe run all the time if you wanted. The near boiler pump would only run when you're burning. If the fire goes out & that pump stops, the BPV should cool off & stop flow through the boiler circuit via its thermostat, so load flow is then only through storage. I'm not sure how good this would work - I'm not sure how much useable heat would be left in your storage by the time the thermostat would close, and I'm not sure how much flow would go in to storage when burning with that primary pump running all the time. Putting a zone valve into your load circuit that only opened when there was a call for heat (and then turned on the primary circ) would be one way to fix that. Making sure the load circuit simply can't flow as much as the boiler loop might be another. Those kinds of things might come down to how easy you can get it done.

There are lots of options in all this stuff - someone might see something in mine that isn't quite right too.

I think to get the most out of your storage, you will need to draw from the top of it after the fire goes out. I just tried to show a way that might be able to be done. The primary could maybe run all the time if you wanted. The near boiler pump would only run when you're burning. If the fire goes out & that pump stops, the BPV should cool off & stop flow through the boiler circuit via its thermostat, so load flow is then only through storage. I'm not sure how good this would work - I'm not sure how much useable heat would be left in your storage by the time the thermostat would close, and I'm not sure how much flow would go in to storage when burning with that primary pump running all the time. Putting a zone valve into your load circuit that only opened when there was a call for heat (and then turned on the primary circ) would be one way to fix that. Making sure the load circuit simply can't flow as much as the boiler loop might be another. Those kinds of things might come down to how easy you can get it done.

There are lots of options in all this stuff - someone might see something in mine that isn't quite right too.

Many things to consider with what you are proposing. I don't see how you can do it with one pump unless the DHW & furnace h/e have zone valves. Describe your DHW (indirect, sidearm electric, ??). Continuing to cycle water thru the loop you are proposing after the boiler burns out will send the coldest water in the tanks thru the DHW and furnace regardless of whether you plumb them in parallel or reverse return like above (not what you want). If you did go that route you would want some kind of check valve to prevent unwanted flow in the loop when boiler is out and the the HP is heating the home or your hot water heater is heating with electricity. The last thing you want to do is heat 500+ gals of water using your HP or your electric water heater. IMHO what you are proposing as a "temp fix" will only lead to frustration and wasted money. Take the time and use a proven solution like in the stickys.

Thanks for correcting the diagram and changing the near boiler pump and primary pump. I was think of moving the primary pump there when I install the tanks anyway. I like the tee idea, I think I will go with that.

I'm not really trying for a tempory fix, more a way to keep it simple. Could it work with manual valve to isolate the

storage from boiler? More like 2 valves, one right next to the tank on the return(on the the boiler side) and one on the supply again on the boiler side.

So, my theory would be when the fire goes out and I want to just heat from storage I close those two valves. There is already

a loop and pump through the storage tanks. Simple at least and very little work or cost and for me might be

permanent. I guess I could even figure out a way with two zone valves tied to the boiler controler or something to make it more automatic. If this is something that is reasonable then I could work on an automatic solution at a later time.

I'm not really trying for a tempory fix, more a way to keep it simple. Could it work with manual valve to isolate the

storage from boiler? More like 2 valves, one right next to the tank on the return(on the the boiler side) and one on the supply again on the boiler side.

So, my theory would be when the fire goes out and I want to just heat from storage I close those two valves. There is already

a loop and pump through the storage tanks. Simple at least and very little work or cost and for me might be

permanent. I guess I could even figure out a way with two zone valves tied to the boiler controler or something to make it more automatic. If this is something that is reasonable then I could work on an automatic solution at a later time.

I don't think I am to worried about the cold water circ. through the DHW or HE if it get cool. I don't think

we will let the boiler and storage get that cool. If there is no heat in the house then I have to turn one

thermostat off and the other on, so there is no automatic back-up heat. Same for the hot water.

we will let the boiler and storage get that cool. If there is no heat in the house then I have to turn one

thermostat off and the other on, so there is no automatic back-up heat. Same for the hot water.

Maple1's revised diagram above looks like what you are after. If you keep up with the firings and don't let the storage get cool it looks like it should work. You could also shut off the electricity to your DHW heater and turn off your HP at the t-stat to avoid accidently "charging" the storage when the storage cools beyond the usable temp. You would lose the automatic backup and may have to ocassionally deal with a cold house or cold shower.

maple1

Minister of Fire

I wouldn't advise using valves between the boiler & storage. If you happen to forget to open something, you might set yourself up for a dangerous overheat situation.

What do you have for overheat protection? Dump zone?

You will have to keep in mind that all the pumps, valves & other gadgets that are shown in a typical piping diagram are not there 'just because'. They are there to provide specific controls, under different typical operating conditions. Some of them very important safety-wise. Removing or over-simpifying can have really bad consequences.

What do you have for overheat protection? Dump zone?

You will have to keep in mind that all the pumps, valves & other gadgets that are shown in a typical piping diagram are not there 'just because'. They are there to provide specific controls, under different typical operating conditions. Some of them very important safety-wise. Removing or over-simpifying can have really bad consequences.

I don't think a overheat could occur . The water would just circulate around the boiler loop and shut off the

blower at the boiler temp set point. Really just like it operates now. I even tested this by accident the first time

I fired the boiler and I the BPV in. Because of the pump location it would not allow any water to circulate through the system.

It worked fine. I do have a dump zone for overtemp.

blower at the boiler temp set point. Really just like it operates now. I even tested this by accident the first time

I fired the boiler and I the BPV in. Because of the pump location it would not allow any water to circulate through the system.

It worked fine. I do have a dump zone for overtemp.

Clarkbug

Minister of Fire

NC, you can have overheat for sure if you have a good raging fire going and you lose a pump or you leave the bypass open or something like that. But since you have a dump zone, you should be Ok (assuming its triggered by heat).

The diagram I posted, and what Im assuming your system does, is operates like an OWB is typically plumbed. The main loop constantly circulates, and the temp of that loop moves up and down depending on if the boiler is firing or is idle. From your posts above, it sounds like you arent intending to batch burn, but you want to keep the boiler running all winter long, relying on the Econoburn controller to adjust the boiler output as needed. If the boiler goes out, the loop continues to pump until you get the fire burning again. So the storage you want to install doesnt act like storage that most folks here with a gasser would put in, but instead its more of a giant buffer tank.

Just know that if the loop temp drops below whatever your boiler protection valve is set at, you might have a hard time getting the loop back up to temp.

Its not the most efficient way, but it is simple and you should be able to do it with minimal other changes to your system. Now if you want to make changes to improve efficiency of your combustion and ability to pull hot water for storage, thats another ball game...

The diagram I posted, and what Im assuming your system does, is operates like an OWB is typically plumbed. The main loop constantly circulates, and the temp of that loop moves up and down depending on if the boiler is firing or is idle. From your posts above, it sounds like you arent intending to batch burn, but you want to keep the boiler running all winter long, relying on the Econoburn controller to adjust the boiler output as needed. If the boiler goes out, the loop continues to pump until you get the fire burning again. So the storage you want to install doesnt act like storage that most folks here with a gasser would put in, but instead its more of a giant buffer tank.

Just know that if the loop temp drops below whatever your boiler protection valve is set at, you might have a hard time getting the loop back up to temp.

Its not the most efficient way, but it is simple and you should be able to do it with minimal other changes to your system. Now if you want to make changes to improve efficiency of your combustion and ability to pull hot water for storage, thats another ball game...

maple1

Minister of Fire

Be sure to let us know what you decide to do - and how it works out. You'll have to arrange your priorities for yourself to get there.

EDIT: Don't forget about an expansion tank.

EDIT: Don't forget about an expansion tank.

Last edited:

I will post back when all is installed and up and running. I still have to get the tanks welded and installed. And, yes I am planning on the expansion tank. The expansion tank might be the most expensive part of the whole project! As of right now I am just running without storage. Thanks for all the help and ideas!

700renegade

Member

NCFord - are you using Maple's diagram? A major improvement will be made if you toggle that primary circulator to only operate when there is a heat call in the house - I don't know where your tanks are located compared to your furnace, but and easy solution is to put the circulator near the furnace and tie the 110v into the furnace fan. A call for heat turns on both the fan and the circ. A limitation is you don't get constant flow thru your water heater sidearm.

You don't want to mix those tanks 24/7 if you can avoid it. Perhaps even throw a throttling valve in the primary loop to slow it down if gpm is higher than needed ( you want as big a dT thru the loop as you can live with )

You mention buying some valves to isolate parts of the system - With the price of brass nowdays it wouldn't take long to equal a $70 pump.

There are some better solutions to this that would involve a tempering valve or a smart pump but I don't think you're inclined to go there.

You don't want to mix those tanks 24/7 if you can avoid it. Perhaps even throw a throttling valve in the primary loop to slow it down if gpm is higher than needed ( you want as big a dT thru the loop as you can live with )

You mention buying some valves to isolate parts of the system - With the price of brass nowdays it wouldn't take long to equal a $70 pump.

There are some better solutions to this that would involve a tempering valve or a smart pump but I don't think you're inclined to go there.

Last edited:

700renegade, I am thinking of tying the primary pump to a call for heat as you pointed out, real easy to do.

maple1

Minister of Fire

If you put in a VS pump, such as a Grundfos Alpha, for your primary pump, you will be able to control your load flows very well and it will use less electricity as well. If you try to throttle a regular pump, it will keep spinning the same rate & you will be loading it. If you throttle an Alpha, it will just slow itself down to maintain a constant pressure drop and hopefully you can reduce the flow to where you want. Alphas cost more than their comparable 15-58, but IMO they are well worth the extra cost. Plus they have that neat digital readout telling you what they're doing.

Yes, I would try to tie to demand.

Yes, I would try to tie to demand.

Clarkbug

Minister of Fire

NCFord - are you using Maple's diagram? A major improvement will be made if you toggle that primary circulator to only operate when there is a heat call in the house - I don't know where your tanks are located compared to your furnace, but and easy solution is to put the circulator near the furnace and tie the 110v into the furnace fan. A call for heat turns on both the fan and the circ. A limitation is you don't get constant flow thru your water heater sidearm.

You don't want to mix those tanks 24/7 if you can avoid it. Perhaps even throw a throttling valve in the primary loop to slow it down if gpm is higher than needed ( you want as big a dT thru the loop as you can live with )

If the pump is tied to the demand, then the piping of the tanks should change such that the hot water available at the top of the tanks is sent to the load. The diagram I had sent with the tanks on the downstream side of the load wont help you out in that respect. Ill try to send a revised diagram later this evening.

- Status

- Not open for further replies.

Similar threads

- Replies

- 5

- Views

- 734

- Replies

- 9

- Views

- 2K

- Replies

- 5

- Views

- 882

- Replies

- 10

- Views

- 2K