I was a little dismayed when I realized my Heritage was not burning to specs this fall. The beginning of my third winter using this stove. Telling signs were the faster speed at which logs were being consumed and difficulty getting the good, low recirculating burn from low settings. I had been through this once before at the end of my first season with the Heritage. I got a light and looked up at the baffle. A one inch hole was visible in the ceramic plate.

There ya go, thousands of dollars upgrading my stove to this real beauty and it broke down already, after one winter! Oh sure, it was probably my fault. I probably 'shanked' the baffle with my poker or 'rammed' in too much wood. Maybe it was all those times I started the stove by leaving the ash door open that weakened the baffle? So off to the hardware to get a tub of furnace cement. A temporary solution at best. Don't bother is my advice, because this ceramic baffle is a 1/4 inch of, to put it politely, pith and nonsense. To top it off, I found out that it costs $65+ to get a new baffle. Typical, really great, expensive stove, that requires a replacement part every season or two. The ridiculous thing is that Hearthstone would bother with a baffle made of this ceramic stuff because it is too delicate for service in a stove. Of course you're going to 'prang' your stove baffle every so often. I don't care for 'feline-footing' around delicate parts that I need to put to daily use. I read about a fella that got three years out of his Heritage baffle. When I remove mine, it fell apart like pie crust. Oh! oh! Winters comin'!

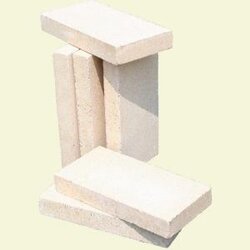

It is obvious that the part makes sense for the service techs at the stove shop because sooner or later your gonna need baffle replacement and that means $$$$ for them. Go look in your Hearthstone right now, I bet you got a hole in your stock baffle. I wasn't going to roll over for these guys down at the shop so easily and they are probably wondering why I haven't been in yet to get a new baffle? I tried a few materials such as heavy ceramic tiles and a piece of asbestos board. Don't bother. Then I found these fire bricks in my old stove that I hadn't taken in for the scrape money yet. They are 4 1/2 x 9 x 1/2 inches and can be purchased at the Home Depot, inexpensively if you don't have any in an old stove. They are durable to heat but a little brittle so careful not to ding or torsion them when handling. The bricks form my old stove are 18 years old.

http://www.homedepot.com/buy/buildi...rts-accessories/6-pack-firebrick-154421.htmlk

For the modification I used a cannister filter mask, safety glasses, a pencil, square and a grinder with a small metal / diamond, cutting / grinding wheel for masonry work available, at the hardware store. Just do a good job smoothing the sides of the bricks that you'll have to cut. After you fit the bricks in, you get a nice row of 1 1/2 inch thick firebrick for a baffle that is much more durable then the 'wafer' that the Heritage comes with. Stove works well again and I not so worried about paying for a stock, junk, baffle material that doesn't appear to be up to the job.

I'd be interested in details of other effective solutions to this Heritage baffle problem but, so far, the stove works well again. Also be interested in reasons why I shouldn't do this type of mod.

There ya go, thousands of dollars upgrading my stove to this real beauty and it broke down already, after one winter! Oh sure, it was probably my fault. I probably 'shanked' the baffle with my poker or 'rammed' in too much wood. Maybe it was all those times I started the stove by leaving the ash door open that weakened the baffle? So off to the hardware to get a tub of furnace cement. A temporary solution at best. Don't bother is my advice, because this ceramic baffle is a 1/4 inch of, to put it politely, pith and nonsense. To top it off, I found out that it costs $65+ to get a new baffle. Typical, really great, expensive stove, that requires a replacement part every season or two. The ridiculous thing is that Hearthstone would bother with a baffle made of this ceramic stuff because it is too delicate for service in a stove. Of course you're going to 'prang' your stove baffle every so often. I don't care for 'feline-footing' around delicate parts that I need to put to daily use. I read about a fella that got three years out of his Heritage baffle. When I remove mine, it fell apart like pie crust. Oh! oh! Winters comin'!

It is obvious that the part makes sense for the service techs at the stove shop because sooner or later your gonna need baffle replacement and that means $$$$ for them. Go look in your Hearthstone right now, I bet you got a hole in your stock baffle. I wasn't going to roll over for these guys down at the shop so easily and they are probably wondering why I haven't been in yet to get a new baffle? I tried a few materials such as heavy ceramic tiles and a piece of asbestos board. Don't bother. Then I found these fire bricks in my old stove that I hadn't taken in for the scrape money yet. They are 4 1/2 x 9 x 1/2 inches and can be purchased at the Home Depot, inexpensively if you don't have any in an old stove. They are durable to heat but a little brittle so careful not to ding or torsion them when handling. The bricks form my old stove are 18 years old.

http://www.homedepot.com/buy/buildi...rts-accessories/6-pack-firebrick-154421.htmlk

For the modification I used a cannister filter mask, safety glasses, a pencil, square and a grinder with a small metal / diamond, cutting / grinding wheel for masonry work available, at the hardware store. Just do a good job smoothing the sides of the bricks that you'll have to cut. After you fit the bricks in, you get a nice row of 1 1/2 inch thick firebrick for a baffle that is much more durable then the 'wafer' that the Heritage comes with. Stove works well again and I not so worried about paying for a stock, junk, baffle material that doesn't appear to be up to the job.

I'd be interested in details of other effective solutions to this Heritage baffle problem but, so far, the stove works well again. Also be interested in reasons why I shouldn't do this type of mod.

!

!