If I ever let my boiler burn out or die I loose all the pressure in my system. My pumps and system seem to run best when I have about 20 psi on it, which I usually do when everything is hot. Once the temperature drops I loose all of the pressure (make sense although I didn't expect it to be this drastic) and my pumps tend to vapor lock or something where the water does not circulate. I wasn't aware of boiler feed valves until I started doing a little googling but apparently they will maintain a constant pressure on the system. Is there any advice as to what I should be looking for on these? I would think I would want an adjustable one but is this necessary? What is the rule of thumb or criteria that I should know about system pressure?

On a similar subject I have two zones in my loft that tend to get air in them. It makes sense that air rises but where is is coming from? I've purged the zones several times and everything will be running smooth for a week or two but eventually the zones quit circulating and seem to have air in them. I've got an air eliminator on my expansion tank in the boiler house but maybe I should also have one in the house or at least on these upper zones?

Any advice or suggestions?

Thanks guys.

On a similar subject I have two zones in my loft that tend to get air in them. It makes sense that air rises but where is is coming from? I've purged the zones several times and everything will be running smooth for a week or two but eventually the zones quit circulating and seem to have air in them. I've got an air eliminator on my expansion tank in the boiler house but maybe I should also have one in the house or at least on these upper zones?

Any advice or suggestions?

Thanks guys.

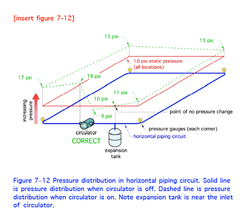

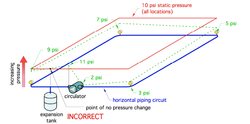

This edition is in color which helps see what this drawing is explaining, better.

This edition is in color which helps see what this drawing is explaining, better.