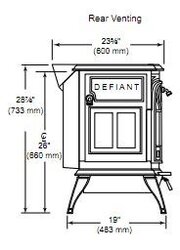

I am just about to purchase the Vermont Castings 2in1 Defiant, but I need to make sure that I would be able to fit it. There is a piece of metal that hangs about 1/2 inch lower than the bricks on the top of the fireplace opening. I'm pretty sure that the top of the flue outlet will be blocked by this piece of metal so I am wondering if it is ok to cut it out of there? It is approximately 2" x 2" piece of angle iron. I wouldn't need to cut the whole piece out, just a few inches off the lower piece in the middle of the fireplace. Does this piece actually serve a purpose or is it just part of the old fireplace?

Thanks.

Thanks.