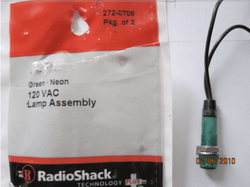

Can any of you electrical gurus point me to a supplier for a small light I can attach to a circulator so I know when it's on?

I know I read about this once, but could not find it.

Thanks, Chris

I know I read about this once, but could not find it.

Thanks, Chris