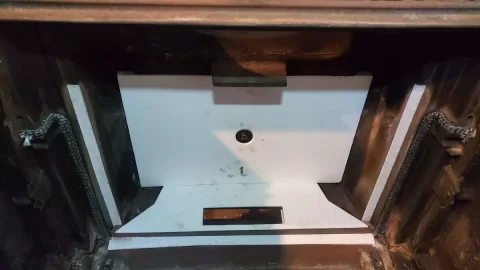

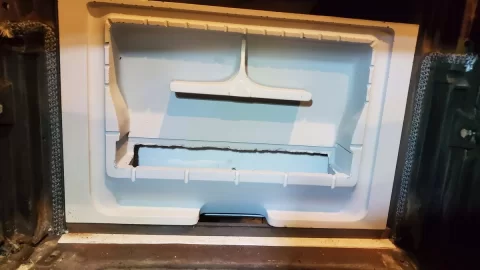

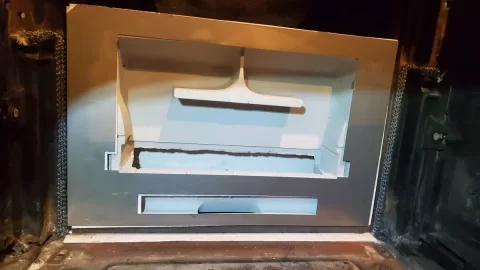

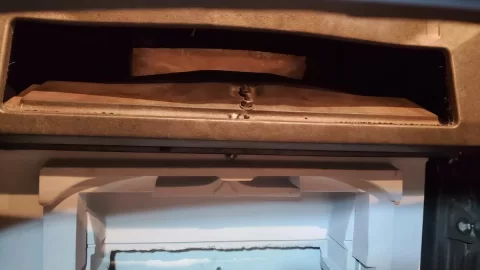

So I woke up Saturday morning and I don't know what got into me but at 6am I started to pull apart my stove. By the time my wife woke up there were stove parts all over the place by 9am I was out in the driveway with a wire brush, air compressor and a number of other tools cleaning it up.

I say its a very interesting stove and not as complicated as I thought.

I say its a very interesting stove and not as complicated as I thought.