Encore 2040 rebuild..

- Thread starter Woodsplitter67

- Start date

-

Active since 1995, Hearth.com is THE place on the internet for free information and advice about wood stoves, pellet stoves and other energy saving equipment.

We strive to provide opinions, articles, discussions and history related to Hearth Products and in a more general sense, energy issues.

We promote the EFFICIENT, RESPONSIBLE, CLEAN and SAFE use of all fuels, whether renewable or fossil.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

I need to correct one of the posts.. when installing the Gaskets between the engine and the fire back. The fireback gets installed, then the stainless steel gasket goes against the engin, the fiberform gasket goes against the stainless steel gasket and the refractory goes against the fiberform gasket so in this order engin,steel gaket,fiber gasket, then refractory

Yes, super helpful information, especially with the pictures.

Using the manual's part descriptions it is: the refractory engine, fiber gasket, then the stainless fireback plate, and finally the refractory fireback.The fireback gets installed, then the stainless steel gasket goes against the engin, the fiberform gasket goes against the stainless steel gasket and the refractory goes against the fiberform gasket so in this order engin,steel gaket,fiber gasket, then refractory

JohnDaileyNH

Feeling the Heat

So I did do my first test fire.. Im pretty sure Its a good job and running well. Its not a full on burn and I didnt close the damper.. so far.. so good

did you burn..Perfect day for the first fire of the year nice and chilly out

did you burn..

Not yet. Sitting in the tree stand since 5, going to get down in an hour to go light up the stove

So here is how the first fire went.. I did more burning than anticipated. The stove ran well... once cooled I will need to do a small adjustment on the primary air flapper... Its not super cold out so draft wasn't where it should be for winter. I did close the damper and get the cat going on just 25% of wood being in the stove and it lit off nicely. I had good control of the stove so I went with a full burn The cat went up to 1240 degrees.. I cut the air back and as usual the temperature did drop some then started to climb as expected..I shut the air down completely and again.. the cat temperature dropped as it should and then worked its way back up to almost where it was with the primary air fully open.. the cat climbed to 1230.. no smoke out of the stack.. looking good guys and gals

So I did my first stove cleanout after burning for about a month and the inside of the stove looked clean. The refractory looked good. The cat in it was what I was running last year.

After burning for over a month and doing many overnight burns and low long day burns. I can say that this stove is not a hard rebuild and I got it correct on the first try.

Knowing VC it best to pre order parts need. Using mountain view hearth is a good resource for parts getting VC parts at a reasonable price.

It seems that the gaskets around the refractory take a beating. Taking off the top of the stove is the easiest way to work on it. Taking off the top is only 1 bolt and 2 nuts

After burning for over a month and doing many overnight burns and low long day burns. I can say that this stove is not a hard rebuild and I got it correct on the first try.

Knowing VC it best to pre order parts need. Using mountain view hearth is a good resource for parts getting VC parts at a reasonable price.

It seems that the gaskets around the refractory take a beating. Taking off the top of the stove is the easiest way to work on it. Taking off the top is only 1 bolt and 2 nuts

I like the design of the Encore better than my stove after seeing your rebuild. The air routing makes logical sense and so does the location of the cat.So I did my first stove cleanout after burning for about a month and the inside of the stove looked clean. The refractory looked good. The cat in it was what I was running last year.

After burning for over a month and doing many overnight burns and low long day burns. I can say that this stove is not a hard rebuild and I got it correct on the first try.

Knowing VC it best to pre order parts need. Using mountain view hearth is a good resource for parts getting VC parts at a reasonable price.

It seems that the gaskets around the refractory take a beating. Taking off the top of the stove is the easiest way to work on it. Taking off the top is only 1 bolt and 2 nuts

View attachment 319209 View attachment 319210 View attachment 319211

The Dauntless cat location being horizontal to the fire box right behind my cover seems stupid. Direct flame impingment seems way more possible in my design's case than yours.

Since heat and smoke rise through your cat, as opposed to the draft needing to suck the smoke and heat through the dauntless and then up the flu is just silly to me.

Now I understand why the bigger stoves run so much different than mine and why draft differences between the two types show such different results.

Great write up.

Thanks a ton!

I like the design of the Encore better than my stove after seeing your rebuild. The air routing makes logical sense and so does the location of the cat.

The Dauntless cat location being horizontal to the fire box right behind my cover seems stupid. Direct flame impingment seems way more possible in my design's case than yours.

Since heat and smoke rise through your cat, as opposed to the draft needing to suck the smoke and heat through the dauntless and then up the flu is just silly to me.

Now I understand why the bigger stoves run so much different than mine and why draft differences between the two types show such different results.

Great write up.

Thanks a ton!

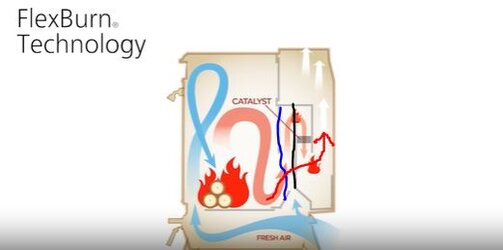

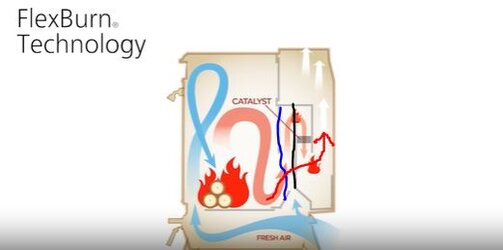

So just to clarify.. this is a downdraft stove.. from the firebox...the air enters the top of the combuster.. exists out the bottom of the combuster .. then goes up the back of the stove into the stovepipe

The rebuilding process was kinda cool

AsylumResident

Feeling the Heat

Sorry,

I said horizontal on the duantless, and I should have said parallel to the firebox. Your explaination makes sense after I looked at the VC website and found the below diagram.

The encore cat is horizontally mounted.

Mine is drastically different!

The dauntless has small air holes at the back of the fire box, on the front side of the refractory, down low, just below the ceramic inspection plate. I drew on this one how mine is set up. The blue line represents my ceramic inspection plate where the hot gases enter. I drew a new red line of the direction of my hot gases in a red line.

The black line is my cat location and then the gases travel up and out the back of the stove to the chimney pipe.

I said horizontal on the duantless, and I should have said parallel to the firebox. Your explaination makes sense after I looked at the VC website and found the below diagram.

The encore cat is horizontally mounted.

Mine is drastically different!

The dauntless has small air holes at the back of the fire box, on the front side of the refractory, down low, just below the ceramic inspection plate. I drew on this one how mine is set up. The blue line represents my ceramic inspection plate where the hot gases enter. I drew a new red line of the direction of my hot gases in a red line.

The black line is my cat location and then the gases travel up and out the back of the stove to the chimney pipe.

OK,

@Woodsplitter67 We had a warmer day yesterday, so I could shut the stove down and I wanted to take some photos to better explain my diagram above this post. These Dauntless stoves are quite a bit different than yours.

The first photo is the firebox with the Refractory cover.

The second photo shows how the cat is oriented in the Dauntless 2115 2n1 Flexburn I have. Now you can see how direct flame impingment could be an issue with my stove.

Keep in mind, this is the original cat, one year old and close to 8months of 24x7 use (about 5,700hours).

The third photo is with the Cat removed. I think this design is why draft doesn't change a single bit with/without the Catalyst. The Dauntless is not really a full down draft since the gases pass through that catalytst, make a 90degree turn up and meet the flu pipe just behind the bypass damper flap as show in the 4th photo.

The last picture shows a small amount of spalling I am seeing inside the refractory on the back side of the catalyst area (because I don't monitor my cat temps). This one is on me

@Woodsplitter67 We had a warmer day yesterday, so I could shut the stove down and I wanted to take some photos to better explain my diagram above this post. These Dauntless stoves are quite a bit different than yours.

The first photo is the firebox with the Refractory cover.

The second photo shows how the cat is oriented in the Dauntless 2115 2n1 Flexburn I have. Now you can see how direct flame impingment could be an issue with my stove.

Keep in mind, this is the original cat, one year old and close to 8months of 24x7 use (about 5,700hours).

The third photo is with the Cat removed. I think this design is why draft doesn't change a single bit with/without the Catalyst. The Dauntless is not really a full down draft since the gases pass through that catalytst, make a 90degree turn up and meet the flu pipe just behind the bypass damper flap as show in the 4th photo.

The last picture shows a small amount of spalling I am seeing inside the refractory on the back side of the catalyst area (because I don't monitor my cat temps). This one is on me

Similar threads

- Replies

- 3

- Views

- 1K

- Replies

- 6

- Views

- 529

- Replies

- 32

- Views

- 4K

- Replies

- 4

- Views

- 929