Garn It!

- Thread starter rvtgr8

- Start date

-

Active since 1995, Hearth.com is THE place on the internet for free information and advice about wood stoves, pellet stoves and other energy saving equipment.

We strive to provide opinions, articles, discussions and history related to Hearth Products and in a more general sense, energy issues.

We promote the EFFICIENT, RESPONSIBLE, CLEAN and SAFE use of all fuels, whether renewable or fossil.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

- Status

- Not open for further replies.

Rick Stanley

Feeling the Heat

Robert, I've been asking dumb questions in here for so long that I can actually contribute some, at times. That's what makes this a cool place.

Jim K in PA

Minister of Fire

slowzuki said:Jim do you have 2" with a minimal number of fittings up to the suction side of your pumps and is your main pump high capacity? It doesn't take many fittings to add friction.

Ken - in a moment of haste, I bushed the outlet of the GARN down to 1.5". I have two 90s before the Grundfos 43-44, which is a high volume, low head pump. After the pump there are 5 more elbows and a brass flapper one way valve.

I thought about going 2" all the way to the pump, and then stepping down at the outlet flange or after the next elbow. I was so far behind schedule wise I piped it all in 1.5" just to get going. Part of the learning process. 8-/

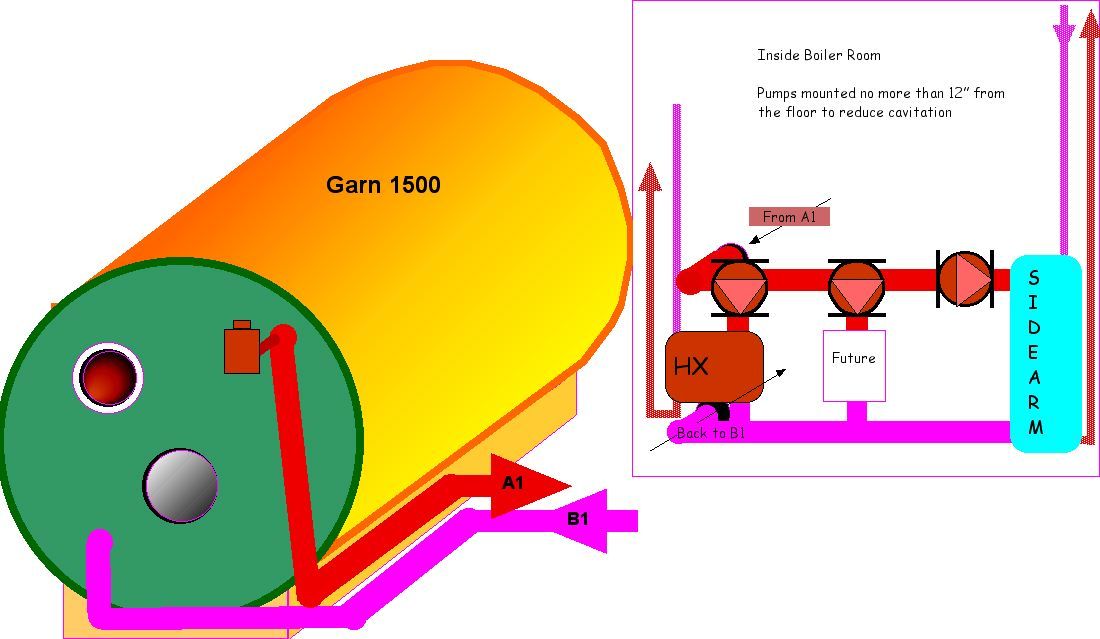

This drawing is pretty lame and needs some explanation. The next post will show boiler placement and should help this pic. make sense.

My Garn is in the first stall of the garage that is no more. My boiler room is directly adjacent to the Garn. I will be bringing the Garn hot water out and down to the garage floor, swing to the side of it and go straight through the wall into the existing boiler room and into the the manifold hung on the wall. I have drawn the manifold in the box in the upper right side of the picture. The pipe will be full 2" black steel for a full 8' before any circ motor. The HX a full 90 plate miracle of manufacturing. I have not yet sized the circulating pump and will solve the mixing problem as soon as I decide on the placement of the manifold

My Garn is in the first stall of the garage that is no more. My boiler room is directly adjacent to the Garn. I will be bringing the Garn hot water out and down to the garage floor, swing to the side of it and go straight through the wall into the existing boiler room and into the the manifold hung on the wall. I have drawn the manifold in the box in the upper right side of the picture. The pipe will be full 2" black steel for a full 8' before any circ motor. The HX a full 90 plate miracle of manufacturing. I have not yet sized the circulating pump and will solve the mixing problem as soon as I decide on the placement of the manifold

slowzuki

Minister of Fire

I'll try to run some numbers but you may need to go up to 2.5" if having 8 ft of pipe plus fittings before the pump but that layout is the simplest way to do it.

Slowzuki,

I can't thank you enough for taking the time to look at this problem. I do have a question on your last posting and please forgive my ignorance, but if the hot water that leaves the Garn comes out of a 2" tapped hole, won't the 2.5" steel pipe be bottlenecked and thereby less effective? Perhaps I need to place the manifold on the garage side of the system where it has less black steel before the circulators. I was under the impression that a minimum of 6' of black steel should be maintained before I put in my first pump. Can a pump with metals that allow for less corrosion (i.e. non-brass) be inserted closer to the Garn which would eliminate the need for this 6' problem?

I hope I am not sounding too idiotic.

Robert

I can't thank you enough for taking the time to look at this problem. I do have a question on your last posting and please forgive my ignorance, but if the hot water that leaves the Garn comes out of a 2" tapped hole, won't the 2.5" steel pipe be bottlenecked and thereby less effective? Perhaps I need to place the manifold on the garage side of the system where it has less black steel before the circulators. I was under the impression that a minimum of 6' of black steel should be maintained before I put in my first pump. Can a pump with metals that allow for less corrosion (i.e. non-brass) be inserted closer to the Garn which would eliminate the need for this 6' problem?

I hope I am not sounding too idiotic.

Robert

slowzuki

Minister of Fire

I think what Garn is trying to do with their copper/brass rules is to try to have any galvanic corrosion from the interface of the two metals occurs in the pipe and not in the boiler or welded outlet where it is difficult to repair. The iron/steel pumps are the cheapest ones and can be put as close as you like (well, assuming fairly normal sized circulators.)

The 2" tapping does reduce the effectivemess of a 2.5" pipe a bit, but it is far better than using 2" pipe.

The 2" tapping does reduce the effectivemess of a 2.5" pipe a bit, but it is far better than using 2" pipe.

Jim K in PA

Minister of Fire

slowzuki said:I

The 2" tapping does reduce the effectivemess of a 2.5" pipe a bit, but it is far better than using 2" pipe.

Effectiveness in terms of ???? Cavitation? Unless he oversizes the circs on all the legs, I can't imagine he would run out of GPM capacity in a 2" pipe given his intended loads. If Robert places the supply manifold and pumps near the floor, that should give him over 5' of NPSH. Bigger pipe won't increase NPSH.

I'm trying to figure out how to re-pipe my own supply leg while working out yours, Robert. I hope you don't mind . . . :red:

Ken,

Thanks for clearing that up for me. Do you believe the increase in size would get me into the boiler room or should I plan on having the manifold on the outside of the Garn containment enclosure? In addition, the return port on the Garn is even smaller than the 2" hot side. Can I assume that the whole manifold loop would be plumbed in the 2.5" steel?

Thanks for clearing that up for me. Do you believe the increase in size would get me into the boiler room or should I plan on having the manifold on the outside of the Garn containment enclosure? In addition, the return port on the Garn is even smaller than the 2" hot side. Can I assume that the whole manifold loop would be plumbed in the 2.5" steel?

Jim,

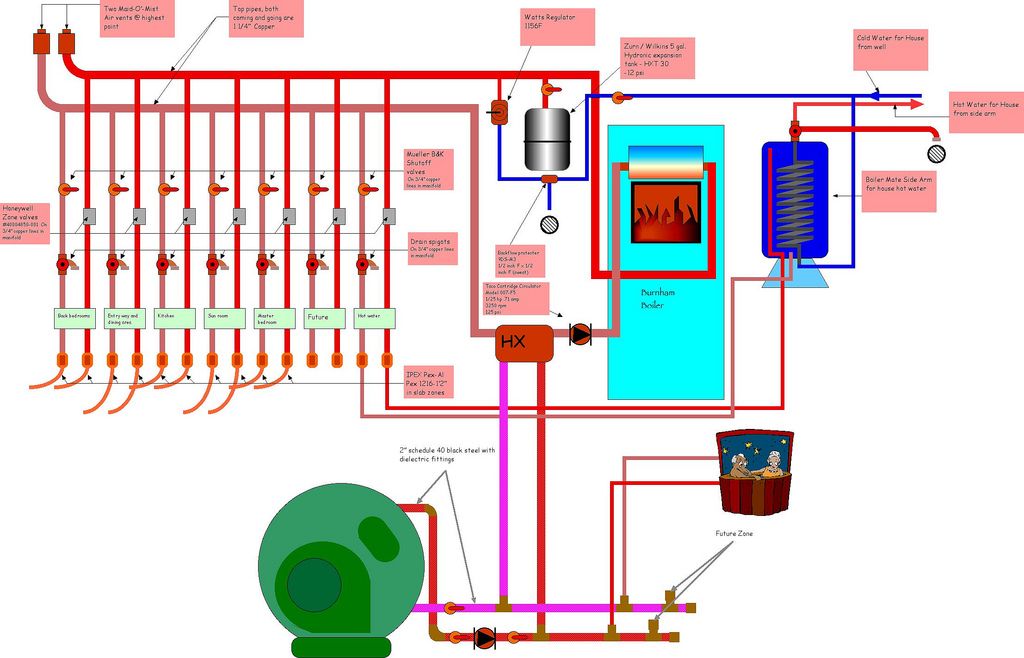

I looked at the flow rates on the difference between 2" and 2.5" pipe and it seems significant in terms of actual flow. I lowered the pumps for the cavitation problem. A 90 plate HX on 2" looks like I can deliver almost the full monty from the Garn (500K+ btu) to the existing system which is rolling along with a Burnham capable of producing 136K btu's. I realize that I will have future loads, is it your opinion that my exchanger should be sized for the maximum amount of output?

PS - No worry about sharing the thread.

I looked at the flow rates on the difference between 2" and 2.5" pipe and it seems significant in terms of actual flow. I lowered the pumps for the cavitation problem. A 90 plate HX on 2" looks like I can deliver almost the full monty from the Garn (500K+ btu) to the existing system which is rolling along with a Burnham capable of producing 136K btu's. I realize that I will have future loads, is it your opinion that my exchanger should be sized for the maximum amount of output?

PS - No worry about sharing the thread.

slowzuki

Minister of Fire

Jim/Robert, I just checked some quick numbers and you should be good with the 2" as long as you don't go crazy with elbows. Jim, bigger pipe will increase the NPSH available at the suction because it reduces the friction loss. Its far more important to control friction loss on the suction than discharge. You can't fix cavitation, but you can pay for increased pumping costs/more powerful pump to solve the other side.

Robert, a 2" return to the tank is a good idea. If you are guaranteed to have all high head circulators it wouldn't matter much but by making it large, it will reduce problems with choosing circulators in the future once you add loads. Besides, it will save you a bit of power while running your circs.

Robert, a 2" return to the tank is a good idea. If you are guaranteed to have all high head circulators it wouldn't matter much but by making it large, it will reduce problems with choosing circulators in the future once you add loads. Besides, it will save you a bit of power while running your circs.

slowzuki

Minister of Fire

Robert, could you share the 90 plate info you have for sizing? I've not sized a HX for a while and don't want to steer you wrong.

rvtgr8 said:Jim,

I looked at the flow rates on the difference between 2" and 2.5" pipe and it seems significant in terms of actual flow. I lowered the pumps for the cavitation problem. A 90 plate HX on 2" looks like I can deliver almost the full monty from the Garn (500K+ btu) to the existing system which is rolling along with a Burnham capable of producing 136K btu's. I realize that I will have future loads, is it your opinion that my exchanger should be sized for the maximum amount of output?

PS - No worry about sharing the thread.

Jim K in PA

Minister of Fire

slowzuki said:Jim/Robert, I just checked some quick numbers and you should be good with the 2" as long as you don't go crazy with elbows. Jim, bigger pipe will increase the NPSH available at the suction because it reduces the friction loss. Its far more important to control friction loss on the suction than discharge. You can't fix cavitation, but you can pay for increased pumping costs/more powerful pump to solve the other side.

Thanks Ken, I was only considering volume, not friction loss.

Robert, a 2" return to the tank is a good idea. If you are guaranteed to have all high head circulators it wouldn't matter much but by making it large, it will reduce problems with choosing circulators in the future once you add loads. Besides, it will save you a bit of power while running your circs.

The reduction to 1.5" at the tank won't negate the gain of the 2" primary piping?

slowzuki

Minister of Fire

Nope it won't negate it. It will be the largest single loss in the loop though. The shape of expanding to 2" does create a larger loss at that single point than leaving 1.5" but you make it back in the pipe and fittings loss. You don't have to use 2", especially if you don't plan on adding a lot of zones right off the boiler.

Ken,

This is stainless steel one. There is one listed on ebay from the same store for half the price that has more copper in it. I don't know if short cuts are wise on the HX Trail.

http://www.flatplate.com/pdf/hydronic/FPbrochure9-99.pdf

This is stainless steel one. There is one listed on ebay from the same store for half the price that has more copper in it. I don't know if short cuts are wise on the HX Trail.

http://www.flatplate.com/pdf/hydronic/FPbrochure9-99.pdf

slowzuki

Minister of Fire

Hmm, I'll have to dig out my heat transfer texts to calc that. They don't give enough info to size it.

Ken,

I fixed my last post. I put in the image instead of the address for the whole pdf. My bad. Should be plenty of information now.

I fixed my last post. I put in the image instead of the address for the whole pdf. My bad. Should be plenty of information now.

slowzuki

Minister of Fire

There is info but you still need to use a formula, they don't provide enough tables to size from their documents.

Jim K in PA

Minister of Fire

Robert - I do not think you need more than the standard FP series unit. The FPN (nickel plated) is for solvent apps, and the MP (multipurpose) series is for marine and pool (Chlor/Bromine apps).

Ken - http://www.flatplate.com/resources_SOFT.htm is the sizing application that is free to use at GEA's web site. You have to register, but it is worth it.

As far as sizing, I think the 90 will exceed what you need substantially, but you will be able to get decent efficiency of heat transfer even as the delta T between the load (house et al.) and the supply (GARN) get closer. That is an expensive unit. Here is an 80 plate with 1.25" fittings that is $785 - http://cgi.ebay.com/GEA-Flatplate-B...20598QQcmdZViewItemQQ_trksidZp1742.m153.l1262

Ken - http://www.flatplate.com/resources_SOFT.htm is the sizing application that is free to use at GEA's web site. You have to register, but it is worth it.

As far as sizing, I think the 90 will exceed what you need substantially, but you will be able to get decent efficiency of heat transfer even as the delta T between the load (house et al.) and the supply (GARN) get closer. That is an expensive unit. Here is an 80 plate with 1.25" fittings that is $785 - http://cgi.ebay.com/GEA-Flatplate-B...20598QQcmdZViewItemQQ_trksidZp1742.m153.l1262

Would a Taco Cast iron 0010-ZF3 flanged out to 2" work on the Garn loop to drive the hot tub, a single old fashioned radiator 12"W x 48"L x 24" T and a 90 plate HX to the old system?

Jim K in PA

Minister of Fire

Robert - I do not have my TACO pump curves handy, but I think the 0010 is plenty. But why not put a valve and pump on the hot tub load, and have the big TACO take of the HX by itself? How will you regulate flow through the hot tub loop? A TACO 007 or Grundfos 15-58 is cheap, under $80 via eBay or Pexsupply.com.

Jim,

I have the opportunity to buy two of the the Taco 0010 ZF3's new in the box for $200. I guess I could use the other one for the hot tub and radiator. Or do you think that that is too much power on the HT loop?

I have the opportunity to buy two of the the Taco 0010 ZF3's new in the box for $200. I guess I could use the other one for the hot tub and radiator. Or do you think that that is too much power on the HT loop?

Jim K in PA

Minister of Fire

rvtgr8 said:Jim,

I have the opportunity to buy two of the the Taco 0010 ZF3's new in the box for $200. I guess I could use the other one for the hot tub and radiator. Or do you think that that is too much power on the HT loop?

Robert - CL add? Those ZF3 pumps are probably not what you want. According to the specs (http://kingsolar.com/catalog/mfg/taco/0010zf3.html) They will only flange up to 1.5". I thought you were going with 2" on your primary manifold. They are WAAAAAy too much flow for the hot tub secondary loop. They are high flow, relatively low head pumps. So, they will be overkill for the HT, but may not be happy with the amount of head loss through the HX.

Those pumps also have integrated switching relay controllers, which you may not want. They are also single speed.

Final thought - yes, you could buy them and use them, and they may work, but consider the above. Sometimes a deal is not such a deal.

BrownianHeatingTech

Minister of Fire

Jim K in PA said:According to the specs (http://kingsolar.com/catalog/mfg/taco/0010zf3.html) They will only flange up to 1.5". I thought you were going with 2" on your primary manifold.

Reducing down to 1.5" just prior to and after the pump would not significantly impede flow.

Joe

- Status

- Not open for further replies.

Similar threads

- Replies

- 0

- Views

- 955

- Replies

- 22

- Views

- 1K

- Replies

- 9

- Views

- 2K

- Replies

- 2

- Views

- 853