I am installing a Jotul 118B into an existing fireplace

The manual wants 3/8 asbestos mill board, which I assume is for insulation from floor joists

I assume asbestos is unavailable and illegal to use nowadays.

What do you use these days instead of asbestos...

Durarock?

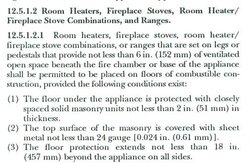

Also, I need to lower the stove a bit, (I need to cut a couple inches of the legs) right now there is about 10" of clearance beneath the stove. I asked the Building Inspector about this, and he said they go only by the manual, that they don't have any codes to go by.

Since the manual does not state minimum clearances for beneath the stove..Is it likely that I can cut the legs without getting an B.S. from the inspector???

Any and all help appreciated....THANKS

The manual wants 3/8 asbestos mill board, which I assume is for insulation from floor joists

I assume asbestos is unavailable and illegal to use nowadays.

What do you use these days instead of asbestos...

Durarock?

Also, I need to lower the stove a bit, (I need to cut a couple inches of the legs) right now there is about 10" of clearance beneath the stove. I asked the Building Inspector about this, and he said they go only by the manual, that they don't have any codes to go by.

Since the manual does not state minimum clearances for beneath the stove..Is it likely that I can cut the legs without getting an B.S. from the inspector???

Any and all help appreciated....THANKS