Hello everyone.

We had a second wood stove, the Jotul F3CB, installed this fall. It was installed by the company who had done a wood stove fireplace insert for us last winter.

I have used the new stove a few times after the break in fires conducted per the manual. On windier than normal days here in the Champlain Islands (every day is windy, to some extent) I notice some smoke puffing back through the stove itself and the 30 degree connectors near the top of the stove pipe assembly. This happens only when I am starting the fire. I wasn't very alarmed by this because once the fire is hot, there is good draw and no visible smoke issues.

Regardless, I still found smoke coming back inside the house displeasing and started to think about relocating the woodstove to create a straight run stove pipe assembly as well as changing over to double walled pipe.

During all of this research I ran across all of the clearances for the stove per the sticker on the back of the heatshield, which wasn't installed (is it always necessary??). Following are some pictures, I hope people here can validate my concerns that this installation is completely FUBARed and offer my some guidance as how to go about dealing with my installer as I'm sure some of you that post here are professionals...

Firstly the interior portion of the install:

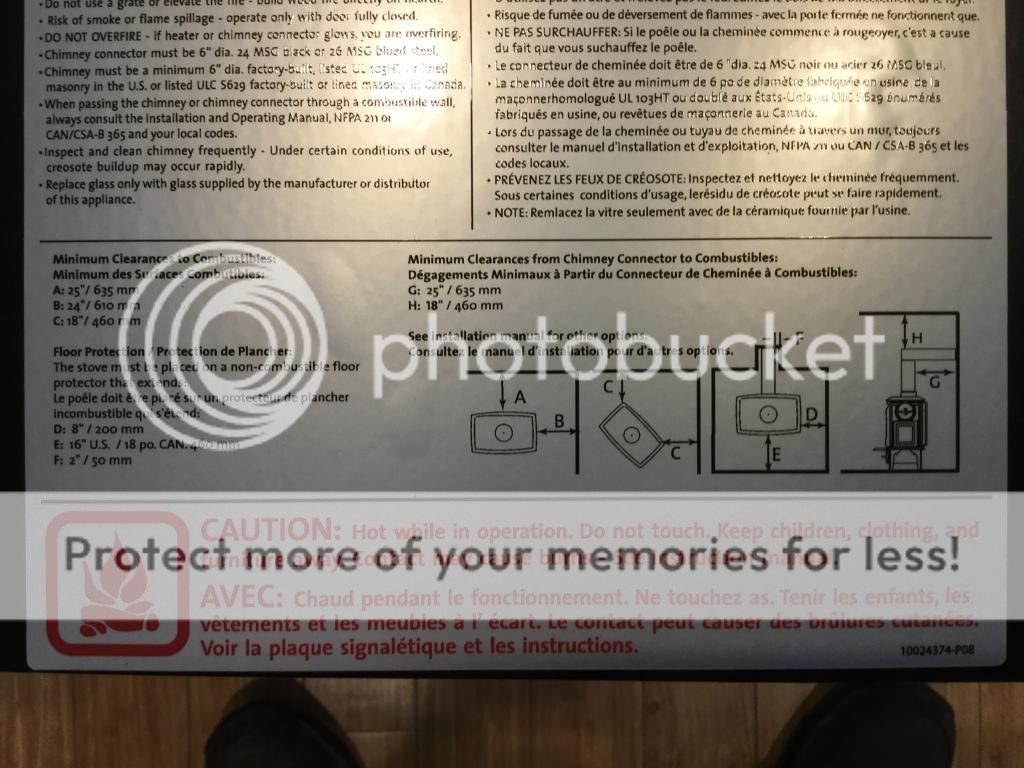

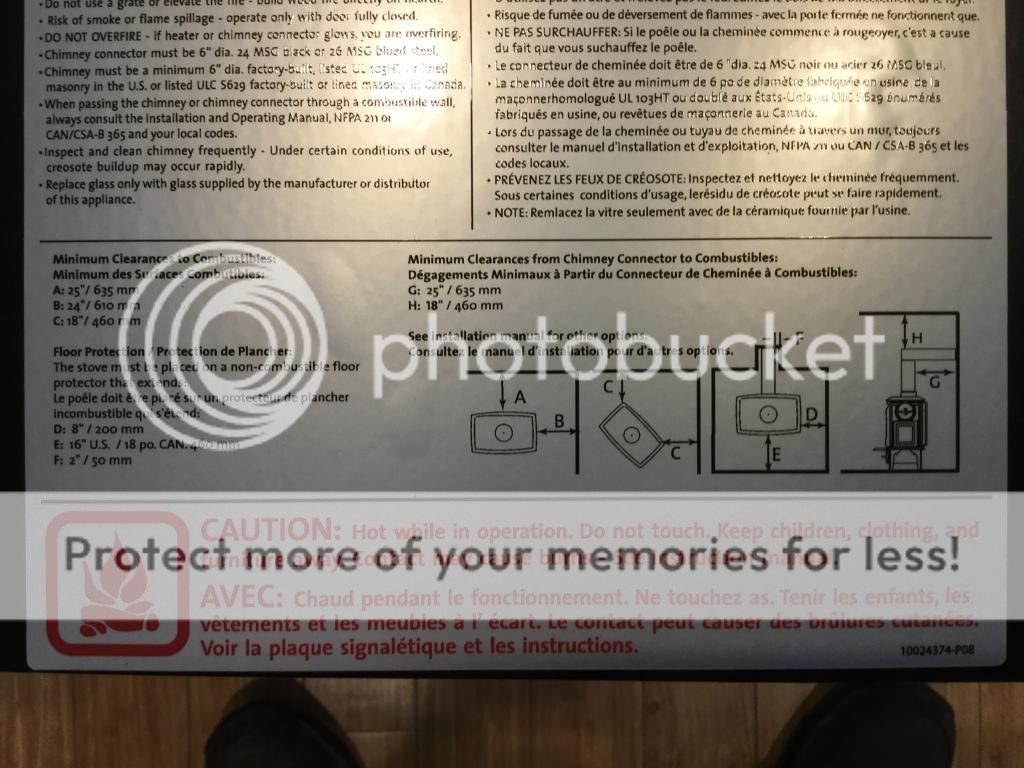

The clearances required:

Measurement (E)16" of hearth or hearth pad required in front of stove. ~10" shown here:

Measurement (C) 18" clearance from corner to combustible material. ~8.25" shown here

I am reading and interpreting everything correctly, aren't I?

We had a second wood stove, the Jotul F3CB, installed this fall. It was installed by the company who had done a wood stove fireplace insert for us last winter.

I have used the new stove a few times after the break in fires conducted per the manual. On windier than normal days here in the Champlain Islands (every day is windy, to some extent) I notice some smoke puffing back through the stove itself and the 30 degree connectors near the top of the stove pipe assembly. This happens only when I am starting the fire. I wasn't very alarmed by this because once the fire is hot, there is good draw and no visible smoke issues.

Regardless, I still found smoke coming back inside the house displeasing and started to think about relocating the woodstove to create a straight run stove pipe assembly as well as changing over to double walled pipe.

During all of this research I ran across all of the clearances for the stove per the sticker on the back of the heatshield, which wasn't installed (is it always necessary??). Following are some pictures, I hope people here can validate my concerns that this installation is completely FUBARed and offer my some guidance as how to go about dealing with my installer as I'm sure some of you that post here are professionals...

Firstly the interior portion of the install:

The clearances required:

Measurement (E)16" of hearth or hearth pad required in front of stove. ~10" shown here:

Measurement (C) 18" clearance from corner to combustible material. ~8.25" shown here

I am reading and interpreting everything correctly, aren't I?