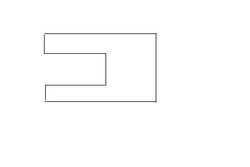

I have a set up where I pull up the splitter onto a pallet that gives me about 9 inches of height,, but thinking of making something else, from wood with outfeed table and wrap around ,or just a higher stand and make some larger wings to attach to my (HF 7 ton splitter. Weight 185 pounds)

I am thinking maybe make some wings to attach where the old ones are that fold up , or maybe not fold up

I hate it when the pieces fall off the back ,and I have to reach over or walk around.

Next would be to do something with the switch , I could wire it up so the motor would run all the time, not sure that's the best idea .

I have a foot switch that will handle the load but , it isn't waterproof so it probably wouldn't be a good idea in the snow .

Yes I would like a better splitter but ,I am just looking to make this one work better .

IDEAS EVERY ONE

I am thinking maybe make some wings to attach where the old ones are that fold up , or maybe not fold up

I hate it when the pieces fall off the back ,and I have to reach over or walk around.

Next would be to do something with the switch , I could wire it up so the motor would run all the time, not sure that's the best idea .

I have a foot switch that will handle the load but , it isn't waterproof so it probably wouldn't be a good idea in the snow .

Yes I would like a better splitter but ,I am just looking to make this one work better .

IDEAS EVERY ONE