We moved into a new (to us) old house and had a chimney sweep of some experience come out and inspect the chimney. He looked up into it and said he'd never seen "something like that" before. Someone had put 2 6" pipes down the rectangular opening side by side, plugged the bottom just above the damper and then poured concrete down from the top to fill the space inside the chimney and outside the pipes. Then (I think) the pipes were removed. The pipes were a few inches apart near the top of the chimney but pressed together near the bottom with the result that the 2 openings merge near the bottom in a figure 8 sort of shape. The chimney is an interior to the building and in good shape. It extends above the roofline, is longer than 14' and there is little or no creosote buildup inside it. I don't know about distance to combustibles from masonry because my xray vision is not what it used to be.

I'd like to install a wood burning stove venting up the chimney for cheap cheap cheap, 3 times cheap. Can I avoid installing a flue liner and just remove the rusted damper and shove a stove pipe up one of the flues, past where they become a single figure 8 type opening?

Can I run it without a cap for a year?

I've been looking for a "hearth stove" with a rear exhaust that will clear the 34" tall opening of the existing fireplace. Is there a good brand?

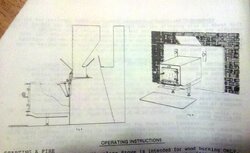

I've got a lead on a used Hearth Mate model DFP-1 for $300. Will that fit? There's some sort of plate involved.... but precious little information.

Is there another brand I should look out for in my search? The tiled hearth area in front of our fireplace is 29" deep. The fireplace is another 18" deep to the rear wall. I'd love to get a basic black box but with a flat top and swanky glass door. All ideas welcome and thanks in advance for your help.

I'd like to install a wood burning stove venting up the chimney for cheap cheap cheap, 3 times cheap. Can I avoid installing a flue liner and just remove the rusted damper and shove a stove pipe up one of the flues, past where they become a single figure 8 type opening?

Can I run it without a cap for a year?

I've been looking for a "hearth stove" with a rear exhaust that will clear the 34" tall opening of the existing fireplace. Is there a good brand?

I've got a lead on a used Hearth Mate model DFP-1 for $300. Will that fit? There's some sort of plate involved.... but precious little information.

Is there another brand I should look out for in my search? The tiled hearth area in front of our fireplace is 29" deep. The fireplace is another 18" deep to the rear wall. I'd love to get a basic black box but with a flat top and swanky glass door. All ideas welcome and thanks in advance for your help.