Sprinter

Minister of Fire

Some general thoughts:

1. Normally, by the time the stove top is at even 300, I would think the secondaries and flue should be plenty hot to start the process of turning the air down. The fire should be rolling well by then. If it isn't, it could be the wood. On my stove, I can start turning air down before that even.

2. A full load, even with large splits, on a large hot bed of coals can invite a runaway. Small splits, probably every time. Try not to reload on too hot or large of a bed, at least not too large a load. Usually best to let your coal bed burn down quite a ways.

3. Try using your larger splits along with the smaller hardwood splits, mixed. The dry wood will tend to compensate for the wetter wood. I think Jeff_t is right that the small splits are drying out quickly. I guess that could be a good part of letting the fire get hot before turning down, up to a point.

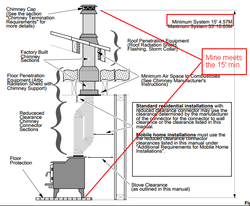

4. On the chimney length, I meant to ask what is the total flue length, stove to top?

1. Normally, by the time the stove top is at even 300, I would think the secondaries and flue should be plenty hot to start the process of turning the air down. The fire should be rolling well by then. If it isn't, it could be the wood. On my stove, I can start turning air down before that even.

2. A full load, even with large splits, on a large hot bed of coals can invite a runaway. Small splits, probably every time. Try not to reload on too hot or large of a bed, at least not too large a load. Usually best to let your coal bed burn down quite a ways.

3. Try using your larger splits along with the smaller hardwood splits, mixed. The dry wood will tend to compensate for the wetter wood. I think Jeff_t is right that the small splits are drying out quickly. I guess that could be a good part of letting the fire get hot before turning down, up to a point.

4. On the chimney length, I meant to ask what is the total flue length, stove to top?