No Wood, Still Winter, Now What? Pg.-1

- Thread starter Rick Stanley

- Start date

-

Active since 1995, Hearth.com is THE place on the internet for free information and advice about wood stoves, pellet stoves and other energy saving equipment.

We strive to provide opinions, articles, discussions and history related to Hearth Products and in a more general sense, energy issues.

We promote the EFFICIENT, RESPONSIBLE, CLEAN and SAFE use of all fuels, whether renewable or fossil.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

- Status

- Not open for further replies.

Jim K in PA

Minister of Fire

Rick Stanley said:Jim, actually I was referring to the other Jim's comparing of garn and wg....

Understood. The change in efficiency (and therefore change in temp rise over time/burn) will happen with any heating appliance, GARN or WG, wood fired or oil, etc. as the water temp rises.

Anyway, what kind of wood are you getting that much rise with? Last nights load was, now that I think of it, was almost all very nice red oak. But during most of these past 3 months, I've burned some pretty crappy stuff. Lot of pitch pine and some red maple dead falls, some kinda punky with good red maple and nice red or white oak mixed in.

But, better days are coming. Made 3 trips with the old skid-dog yesterday. 12 trees mostly oak. Restin today. Snow is deeeep!!

Anyway, whadiyaburnin?

Probably burning 90% red oak at this point, with some black walnut tops here and there. It actually is not as dry as what I started the season with, but it is still in the low 20s MC.

I am just about to the end of my hardwood for this season. I stack my wood shed so that I burn the EWP & Hemlock at the start and end of the season, with the middle 60% of the stack being hardwood. Next week will probably be my last week of hardwood, then it's back to pine. I actually love burning the pine. Virtually no ash to deal with at all.

All in all I did not burn as much this season as I was expecting to, considering how cold it has been this year. I have probably gone through 5+ cord so far, including the pine from Sep->mid Dec. Should be around 8 for the season. If I ever get my butt in gear and get the storm windows built and installed on the house, and actually finish insulating it, I can probably cut another cord or two from the season. :red:

Kemer

Member

Jim How much wood do you put in each load.I'm starting to put more wood in each load and am seeing much better performance with just 2-3 more splits per load.

pybyr

Minister of Fire

Regarding the biobricks mentioned above, unless they work far better in a Garn than the two types of faux-wood I've tried (ecobricks, and some round extruded Canadian product whose name I forget, but which seemed impressively dense and substantial) in my Econoburn, I'd skip them.

The faux-wood stuff does not seem to create or sustain a good coal bed, at least in my experience, and perhaps because of that, it does not seem to net nearly as much heat output (in my downdraft unit) per unit of weight (going by nonscientific but fairly experienced armload savvy) as even semi-seasoned medium-grade (birch, cherry) hardwood.

YMMV in other appliances, but that's my experience to date, and I was so underwhelmed that there's little incentive to experiment further. Mini-pucks like someone on here was trying might work better, in that you could more readily achieve and sustain a bed of hot embers.

The faux-wood stuff does not seem to create or sustain a good coal bed, at least in my experience, and perhaps because of that, it does not seem to net nearly as much heat output (in my downdraft unit) per unit of weight (going by nonscientific but fairly experienced armload savvy) as even semi-seasoned medium-grade (birch, cherry) hardwood.

YMMV in other appliances, but that's my experience to date, and I was so underwhelmed that there's little incentive to experiment further. Mini-pucks like someone on here was trying might work better, in that you could more readily achieve and sustain a bed of hot embers.

TCaldwell

Minister of Fire

I agree with trevor, bio bricks have a totally different burn profile than conventional wood. But in a pinch they mix well with less than optimal wood, kinda like beauty is only a light switch away!

bpirger

Minister of Fire

You know Harry, I think that I have found that if I just put in say 3 or 4 splits trying to get up towards the 190 (say I'm at 170), I seem to get much smaller increase then I'd think. I think typically we put in about 6-8 splits. I do try to place a small piece "vertically" against the pile to deflect the air upwards from the lower intake. Thsi does seem to make a difference.

If I put in more, I know it seems to smoke more. If I put in too little, I don't seem to get half the rise. I assume this is becuase of too much gas fuel and don't get complete combustion (too much wood) or too little gas fuel and perhaps it blows out more than complete burn? Though I wouldn't think that would happen....

But it does seem like there is an optimum amount.

Garn says not to go over half high. My wood is about 23" long, and push towards the refractory with a few inches from the back. But the 6-8 pieces seems to be the sweet spot. Pieces aren't very big, a 10" log would be quarted. Next year I think I will try and leave splits a little bigger. My splitter is only 24", so they won't get much longer, but hopefully be a bit more massive.

If I put in more, I know it seems to smoke more. If I put in too little, I don't seem to get half the rise. I assume this is becuase of too much gas fuel and don't get complete combustion (too much wood) or too little gas fuel and perhaps it blows out more than complete burn? Though I wouldn't think that would happen....

But it does seem like there is an optimum amount.

Garn says not to go over half high. My wood is about 23" long, and push towards the refractory with a few inches from the back. But the 6-8 pieces seems to be the sweet spot. Pieces aren't very big, a 10" log would be quarted. Next year I think I will try and leave splits a little bigger. My splitter is only 24", so they won't get much longer, but hopefully be a bit more massive.

Kemer

Member

I think my sweet spot amount is 9 splits although I don't think I went to 10 yet.I watch my digital flue gauge and some times it goes up fast and some times not.If I pack too tight it goes slow but stays hot longer.The bottom line is if I get it close to 500 I get a big rise.most of the winter I only put 7 slits in If I did 9 I would of used alot less wood.By the way did you install your new controller?

Kemer

Member

mostly standing dead .Lots of oak ,black cherry,other hardwoods but I'm not good at identifying them yet

Jim K in PA

Minister of Fire

Rick - I apparently fill mine much higher than most. Probably more than the manual says, but I have excellent burn performance. I have not counted the splits, and honestly my splits range from small half branches (2-3" diameter) to heavy splits (4-6" diameter) to ultra-dense butt-end pieces (also 4-6" diameter), so I doubt that measure is a good way to compare. I usually fill the box up to about 8" or so from the top, but stack it carefully so there is plenty of side space too. I want to make sure there is no interference in air flow from the upper nozzle to the rear of the fire box. I suppose if I stacked it up against the sides, it would wind up being about half full +/-. My splits are anywhere from 8" long to 24" long (longest I can get through my hydraulic splitter).

It was pretty warm the last few days, with 1 burn every 24-36 hours at most. Got cold again last night though with sleet and snow. :-S

It was pretty warm the last few days, with 1 burn every 24-36 hours at most. Got cold again last night though with sleet and snow. :-S

bpirger

Minister of Fire

Did you know that the ESC key removes a typed messgae? ARGH. I do now.

I've been burning mostly maple and red oak....pretty dry...sitting for over a year under cover and split. No hissing or water seen...no meter either.

I agree that "splits" isn't a good metric...but firebox volume also suffers from amount of ashes in the bed. I have a good 6" at the moment...time for a shovel out.

My key observation is that placing the short piece in front of the bottom air port really helps clean up the smoke. Too much wood, a little smokey. Too little, I don't seem to get the rise I'd expect for the amount of wood. Perhaps this is becuase I'm trying to top off towards the 190...and the transfer efficiency is just lower. Harry, I think looking at the flue temp is a good metric to use.

Do you notice the flue temp being hotter with less temp rise on a second load of wood, becuase of the lower transfer efficiency? Seems like the temp should be measurably hotter longer as the water temp rises. But really a change in water temp of 50 degrees or so should be fairly small compared to a flue gas temp of 2000 degrees coming out of the refractory. (2000-130)/(2000-180) ....just a few percent different. So I really wonder if the refractory temp gets up to 2000 when the amount of wood changes. That would be an interesting measurement...and I'd bet that with a smaller load of wood you don't reach that high temp. Makes sense. And hence there must be a sweet spot...

I've been burning mostly maple and red oak....pretty dry...sitting for over a year under cover and split. No hissing or water seen...no meter either.

I agree that "splits" isn't a good metric...but firebox volume also suffers from amount of ashes in the bed. I have a good 6" at the moment...time for a shovel out.

My key observation is that placing the short piece in front of the bottom air port really helps clean up the smoke. Too much wood, a little smokey. Too little, I don't seem to get the rise I'd expect for the amount of wood. Perhaps this is becuase I'm trying to top off towards the 190...and the transfer efficiency is just lower. Harry, I think looking at the flue temp is a good metric to use.

Do you notice the flue temp being hotter with less temp rise on a second load of wood, becuase of the lower transfer efficiency? Seems like the temp should be measurably hotter longer as the water temp rises. But really a change in water temp of 50 degrees or so should be fairly small compared to a flue gas temp of 2000 degrees coming out of the refractory. (2000-130)/(2000-180) ....just a few percent different. So I really wonder if the refractory temp gets up to 2000 when the amount of wood changes. That would be an interesting measurement...and I'd bet that with a smaller load of wood you don't reach that high temp. Makes sense. And hence there must be a sweet spot...

sparke said:

Oops, missed this post and now, apparently, have missed the listing. It's gone. What did I miss?

91220da

Member

TCaldwell said:Hi rick, Nobody said being a boiler operator is easy, there is always something to do! Do yo have oil or do you have to buy, bioheat fuel value calculator says if you buy oil at $3.44/gal=$460.00/cord. The other way to look at it is if you had to pay $250.00/cord=$1.83/gal. buying more wood is cheaper even at 250 cord if you paid more than 1.83 for the oil in your tank, unless you are sitting home for most of this winter without a income and bought oil in the tank, like me.

Tcaldwell would you have a link to the biofuel heat calculator you mention in this post?

Thanks,

Rich

I am back burning again. Was down almost exactly a month. Been burning for 4-5 days. Managed to get some nice standing dead red oak cut and split.

I seem to be getting tremendous heat transfer. Even better than I got at the beginning of the season. So good that I had forgotten how good a Garn is at putting wood heat into water storage. Three things may be causing this.

1st- the wood is all red oak and very dry, but not like kiln-dried. A few sticks that still had some bark are a little damp, certainly not green but wet and some of the bigger ones are drier on the outside than the inside. It burns great no smoke and very little ash remains. Anyway may be the wood but I doubt it.

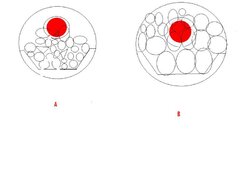

2nd- could be the way I load it up. Jim, I took note of your description of how you load your Garn and tried to mimic that. The diagram shows how I used to do it and how I have done it lately. Like yours?? Anybody else wanna comment on how to load a garn properly??

3rd- I cleaned the flue-tubes while it was shut down. It was a mess. A finely packed black soot coated every surface of every tube. I mean it was PACKED, STUCK, PLASTERED really to the tubes. No creosote like a dirty chimney, just fine soot. Obviously enough to insulate the walls of the tubes. Also have a lot lower stack temps which indicates better transfer. So I want to warn guys about that because I'm not sure what exactly caused this and I'm not entirely sure that I got it clean enough LAST year when I cleaned it because I really had to work to get it clean. Last year I just went in and out with the brush followed by in and out with the vac one pass. I have the right size brushes from garn and a nice fiberglass rod and I had to really scrub back and forth over again to really get it CLEAN. And the reaction chamber was coated nearly quarter inch thick with gray ash material that was difficult to remove because the chamber material is the same color and kind of a soft easily crumbled material. This gray stuff was curled up like corn flakes on the surface. So, if anyone has comments on cleaning a garn properly that would be good also.

I seem to be getting tremendous heat transfer. Even better than I got at the beginning of the season. So good that I had forgotten how good a Garn is at putting wood heat into water storage. Three things may be causing this.

1st- the wood is all red oak and very dry, but not like kiln-dried. A few sticks that still had some bark are a little damp, certainly not green but wet and some of the bigger ones are drier on the outside than the inside. It burns great no smoke and very little ash remains. Anyway may be the wood but I doubt it.

2nd- could be the way I load it up. Jim, I took note of your description of how you load your Garn and tried to mimic that. The diagram shows how I used to do it and how I have done it lately. Like yours?? Anybody else wanna comment on how to load a garn properly??

3rd- I cleaned the flue-tubes while it was shut down. It was a mess. A finely packed black soot coated every surface of every tube. I mean it was PACKED, STUCK, PLASTERED really to the tubes. No creosote like a dirty chimney, just fine soot. Obviously enough to insulate the walls of the tubes. Also have a lot lower stack temps which indicates better transfer. So I want to warn guys about that because I'm not sure what exactly caused this and I'm not entirely sure that I got it clean enough LAST year when I cleaned it because I really had to work to get it clean. Last year I just went in and out with the brush followed by in and out with the vac one pass. I have the right size brushes from garn and a nice fiberglass rod and I had to really scrub back and forth over again to really get it CLEAN. And the reaction chamber was coated nearly quarter inch thick with gray ash material that was difficult to remove because the chamber material is the same color and kind of a soft easily crumbled material. This gray stuff was curled up like corn flakes on the surface. So, if anyone has comments on cleaning a garn properly that would be good also.

Attachments

shoeboxlen

Member

maybe a dumb idea but i would have installed heat tape around the above ground portion and run the power wire in the wall where i could plug it in in case of this type of thing.

TCaldwell

Minister of Fire

Jim K in PA

Minister of Fire

Rick - your diagrams are good, but the SRC tube is lower on the cross section then you depict it. I typically do not stack it tight against the walls, but do stack the splits to about the height you show in "B". Think pyramid-shaped.

I think your increase in efficiency is likely due to BOTH the (presumably) lower moisture content of the wood, and the cleaned HX tubes. I also suspect that the wood you were burning was much higher in MC than you may have known or realized. Do you have a moisture meter? If not, pony-up the $30 and get one. It will really give you a better understanding of what "feels" dry and what IS dry.

I think your increase in efficiency is likely due to BOTH the (presumably) lower moisture content of the wood, and the cleaned HX tubes. I also suspect that the wood you were burning was much higher in MC than you may have known or realized. Do you have a moisture meter? If not, pony-up the $30 and get one. It will really give you a better understanding of what "feels" dry and what IS dry.

Sawyer

Minister of Fire

Rick, I loaded mine full every load I could. My typical load was 150#-170# of 10-15%MC hard maple and yellow birch. I was getting about 6,300BTU/pound of wood. I weighed my wood till I left for vacation March 10th. These results were quite typical and gave me the opportunity to "top off" in the -teen temperatures without boiling.

- Status

- Not open for further replies.

Similar threads

- Replies

- 16

- Views

- 2K

- Replies

- 35

- Views

- 7K

- Replies

- 19

- Views

- 4K

- Replies

- 8

- Views

- 2K