DexterDay.

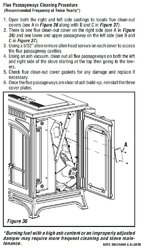

I forgot to mention I did hit the back of the firebox with a mallet. I did run the vacuum at the same time, but did not seem to pick up any soot. Blowing canned air down did not seem to produce lots of soot either.

Next steps would be to find some bottle brushes or dryer lint brushes. Plus take the leaf blower to the vent.

I don't have an air compressor hence the canned air. And yes I understand the air compress is better than the canned air.

Smokey, I won't run the stove till I replace the gasket. I do understan about CO2, but was hoping I could get a get test to determine if I had made any improvements in running the stove.

I will touch base when I clean out the area behind the firebox and take a leaf blower to the vent.

thanks for all the help.

Rick.....

I forgot to mention I did hit the back of the firebox with a mallet. I did run the vacuum at the same time, but did not seem to pick up any soot. Blowing canned air down did not seem to produce lots of soot either.

Next steps would be to find some bottle brushes or dryer lint brushes. Plus take the leaf blower to the vent.

I don't have an air compressor hence the canned air. And yes I understand the air compress is better than the canned air.

Smokey, I won't run the stove till I replace the gasket. I do understan about CO2, but was hoping I could get a get test to determine if I had made any improvements in running the stove.

I will touch base when I clean out the area behind the firebox and take a leaf blower to the vent.

thanks for all the help.

Rick.....