Hi guys I just got my self a used pb105 pellet boiler and I just installed it in my garage to heat it, anyways I'm getting a issue were the unit will start the fire and feet in in 3 cycles and then just stop and never feed the fire again unless I move the feed knobs to test and back, so fare I have change my aquastat and my ingniter as they were both bad, any ways I have cleaned the boiler as good as i can, now after i have a good flame and the feed moter is set to 4 it will run for about 30 seconds and stay off for 30 - 1 minute, but it will only due that cycle 3 times and stop this also happens in every other feed setting just at different timings, I also have the igniter light always on even after the flame, witch to me seems to be why the previous igniter went bad, Any idea where I should start ?e

Pb105 pellet boiler not running after ignition

- Thread starter bill kras

- Start date

-

Active since 1995, Hearth.com is THE place on the internet for free information and advice about wood stoves, pellet stoves and other energy saving equipment.

We strive to provide opinions, articles, discussions and history related to Hearth Products and in a more general sense, energy issues.

We promote the EFFICIENT, RESPONSIBLE, CLEAN and SAFE use of all fuels, whether renewable or fossil.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Mr._Graybeard

Feeling the Heat

Assuming the light on the control panel is not blinking ... since the auger is feeding, we might rule out an air leak for now. Just for fun you might kill power to the boiler for a minute or two to see if the control board resets.

The aquastat can be touchy. I've heard of people putting the spring from a retractable ball-point pen into the well to ensure the sensor was making good contact. Never had to do it myself.

Gotta wonder about the condition of the exhaust sensor probe (ESP). A bad one can make the burner do funny things.

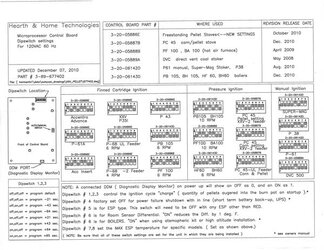

I'd check the dip switches at the top of the control panel to see if they've been played with. Search the forum archives for information on those. The control panel label may conceal them; if so, that's probably a good thing as it means nobody has tinkered with them.

Finally, if the igniter is staying on despite the pellet feed interruption, the control board may be shot. A new one is a couple hundred bucks, so I'd rule out the other possibilities first.

I've gotten technical advice from Earth Sense (Pellethead.com). You can call them or chat online. You might talk with them before loading the parts cannon. Have the serial number of your unit handy when you reach them.

The aquastat can be touchy. I've heard of people putting the spring from a retractable ball-point pen into the well to ensure the sensor was making good contact. Never had to do it myself.

Gotta wonder about the condition of the exhaust sensor probe (ESP). A bad one can make the burner do funny things.

I'd check the dip switches at the top of the control panel to see if they've been played with. Search the forum archives for information on those. The control panel label may conceal them; if so, that's probably a good thing as it means nobody has tinkered with them.

Finally, if the igniter is staying on despite the pellet feed interruption, the control board may be shot. A new one is a couple hundred bucks, so I'd rule out the other possibilities first.

I've gotten technical advice from Earth Sense (Pellethead.com). You can call them or chat online. You might talk with them before loading the parts cannon. Have the serial number of your unit handy when you reach them.

Yea my dip switches are all off and there are about 3-4 that ate visible so im usuming that there are the only ones connected, or in use, I channged the aquastate as i got a 7 blunk code from the static light, after changing it i no-longer gets a status blink so i was thinking to just get a New bord and a new ESP sensor , but what about the air part leak im not understanding the unit as. It also has This sensor with almost black ink in a clear hose right where the intake is any idea what that sensor does and what the black liquid is in side of it ?Assuming the light on the control panel is not blinking ... since the auger is feeding, we might rule out an air leak for now. Just for fun you might kill power to the boiler for a minute or two to see if the control board resets.

The aquastat can be touchy. I've heard of people putting the spring from a retractable ball-point pen into the well to ensure the sensor was making good contact. Never had to do it myself.

Gotta wonder about the condition of the exhaust sensor probe (ESP). A bad one can make the burner do funny things.

I'd check the dip switches at the top of the control panel to see if they've been played with. Search the forum archives for information on those. The control panel label may conceal them; if so, that's probably a good thing as it means nobody has tinkered with them.

Finally, if the igniter is staying on despite the pellet feed interruption, the control board may be shot. A new one is a couple hundred bucks, so I'd rule out the other possibilities first.

I've gotten technical advice from Earth Sense (Pellethead.com). You can call them or chat online. You might talk with them before loading the parts cannon. Have the serial number of your unit handy when you reach them.

Mr._Graybeard

Feeling the Heat

If you have a big air leak (like an open firebox door) the unit will not feed any pellets. That's a neat feature because you can turn the feed dial to "test" while cleaning the firebox and the negative pressure from the running combustion fan will keep the fine ash from blowing in your face. You were getting an abbreviated feed, but you were getting *something,* so if you have a leaky door gasket somewhere it isn't stopping the feed.

I don't believe all the dip switches should be "off" or "down," but I have a later model with a different igniter, so my settings may be different. It's all fine tuning anyway. If you think the board is bad (and it could be), check with Earth Sense. They have techs who will answer questions, at least they have for me in the past.

I don't believe all the dip switches should be "off" or "down," but I have a later model with a different igniter, so my settings may be different. It's all fine tuning anyway. If you think the board is bad (and it could be), check with Earth Sense. They have techs who will answer questions, at least they have for me in the past.

I have read a bunch of threads. Now I found

Out that blocking the intake with something biulds up my fire very fast and keeping the rag over. The intake keeps my fore strong with put the needs pf pellets every 30 seconds the only issue is the feed motor will only feed in 3 forma and stop after words . The fire will eventually die out but at least it now stays list for a while

Out that blocking the intake with something biulds up my fire very fast and keeping the rag over. The intake keeps my fore strong with put the needs pf pellets every 30 seconds the only issue is the feed motor will only feed in 3 forma and stop after words . The fire will eventually die out but at least it now stays list for a while

Mr._Graybeard

Feeling the Heat

Bill, I finally got around to checking my boiler to look for the tube with "black ink" in it. My boiler has two tubes near the intake: one smaller tube above the intake goes to the vacuum sensor and the other larger tube to the left of the intake goes to the pellet feed box. I don't believe either should have any fluid in them, particularly the smaller tube. How moisture got into either is beyond me, although some wet pellets could have fed moisture into the larger tube, I suppose.

Clear those tubes out and see if that improves your boiler's performance.

Clear those tubes out and see if that improves your boiler's performance.

Yea I cleaned them they weren’t dirty at all just was some marks on the outside of the line but I just change my esp senor so hopefully this will work cutely giving it. A go also my vacuum sensor only had a. Line straight tio the lower box intake so?Bill, I finally got around to checking my boiler to look for the tube with "black ink" in it. My boiler has two tubes near the intake: one smaller tube above the intake goes to the vacuum sensor and the other larger tube to the left of the intake goes to the pellet feed box. I don't believe either should have any fluid in them, particularly the smaller tube. How moisture got into either is beyond me, although some wet pellets could have fed moisture into the larger tube, I suppose.

Clear those tubes out and see if that improves your boiler's performance.

Also the new esp didn’t fix anything it still will only start and feed for a couple time then die off any give out a 5 blink error code that meens igniter could not ignite and. Unit is put to off mode even thew it does start the fire it keeps thinking it doesn’t why PB105 i wish i could knowYea I cleaned them they weren’t dirty at all just was some marks on the outside of the line but I just change my esp senor so hopefully this will work cutely giving it. A go also my vacuum sensor only had a. Line straight tio the lower box intake so?

Former Farmer

Minister of Fire

I have a 2006 pb105 pellet boiler with the 3-20-05630A board any idea witch dip switch i should have on?

as of right now i have all them off and the opening is only for the first 3 so I'm assuming they are the only ones that are actually are

unsalable ?

as of right now i have all them off and the opening is only for the first 3 so I'm assuming they are the only ones that are actually are

unsalable ?

Former Farmer

Minister of Fire

Use the diagram for the PB105 switch settings. If you have the finned igniter, all would be off but #5 would be on with RED ESP sensor. Other than Red, set it off.

By the sounds of things, if you change the switch setting on #5, it should take care of your issues. I believe that the wires on the newer ESP probes are RED.

The first three set the amount of time the unit feeds pellets during the initial feed. These are used to fine tune your startup.

By the sounds of things, if you change the switch setting on #5, it should take care of your issues. I believe that the wires on the newer ESP probes are RED.

The first three set the amount of time the unit feeds pellets during the initial feed. These are used to fine tune your startup.

YEA I hade them all off. I also had changed the ESP to the original and still no differences I keep the 5th dip switch off as i have the 2 black wires esp sensor and it is the same one from beforeUse the diagram for the PB105 switch settings. If you have the finned igniter, all would be off but #5 would be on with RED ESP sensor. Other than Red, set it off.

By the sounds of things, if you change the switch setting on #5, it should take care of your issues. I believe that the wires on the newer ESP probes are RED.

The first three set the amount of time the unit feeds pellets during the initial feed. These are used to fine tune your startup.

As of right now my unit will fire right up if i keep a rag to sock over the intake an did will run the pellet feed for 3-4 round on and off primly 17 seconds each time, while the sock keep the flame lasting longer than without as less air is blowing thought the holes in the burntpot but after the rounds of feeding the unit decides not to feed anymore and after about 5 minutes the 5 states blink error will come on indicating that the fire would not start, I have changed my aqua stat and my ESP with original parts I am thinking to change my mother board and give it a shot but that is also the most expensive part on this unite so i am changing anything else before I make that decision, could it possibly be the vacuum sensor I don't know what tells the computer that the flame has started what ever that is im assuming its bad any idea to what tells the unit that there is a fire

Former Farmer

Minister of Fire

its OEM I bought it on amazon and it says its a original Harmon partIs the new ESP an OEM (Harman) part or an aftermarket part?

Well I just retried my unit and it worked out better the fire started in under 5 minutes got the water temp to about 120 and then the issues came back but the feed mote was feeding pellet's for more than 3 rounds I believe it started feeding much more rounds keeping the fire going , this was the first time it has done this so I believe I need to open the lines on my vacuum sensor may where the tube goes in to there cold possibly be builds up of ash, Also Just some back ground Infor I bought this used from a guy who used it for littlie use he never cleaned it so I remember cleaning it in the summer and it was loaded with ash even to the top of the igniter and in the auger to the plate the opens the pellet down so I wouldn't be surprise if ash made it up to that spot where that line from the sensor goes to any one else recommend any other spots I should check for ash other than where the igniter is and the esp exhaust and auger opening plate I cleaned all them spots and the small door where the exhaust air goes out from the hot water exchanger Let me know if you guys have ever cleaned any other spots I will cleaned the sensor line tomorrow and keep you guys posted.

Ok guys I final have some good news I cleaned everything by taking the intake off and I had to put a new silicone gasket all the way around the intake I also pulled the vacuum sensor clear hose high than where it was in side the intake, it seemed like it was way to low to be reading a good level as it was touching the metal so I raised it a bit and silicone everything back together I also noticed that where the pellet flame is there is a rubber gasket around everything and it was all shot so I took everything out and replaced it and everything seems to be working fine now, so no more sock needed to keep my boiler somewhat alive and the feed is now constantly feeding the flame and keeping the fire huge until my max temp it retch. So in end if any one is getting a start fire and it leads to no feed and dies out most likely its a bad leak caused from old gaskets around the flame box, if i had know I would have done this before changing the previous sensors. I will include a video on what I did exactly...Well I just retried my unit and it worked out better the fire started in under 5 minutes got the water temp to about 120 and then the issues came back but the feed mote was feeding pellet's for more than 3 rounds I believe it started feeding much more rounds keeping the fire going , this was the first time it has done this so I believe I need to open the lines on my vacuum sensor may where the tube goes in to there cold possibly be builds up of ash, Also Just some back ground Infor I bought this used from a guy who used it for littlie use he never cleaned it so I remember cleaning it in the summer and it was loaded with ash even to the top of the igniter and in the auger to the plate the opens the pellet down so I wouldn't be surprise if ash made it up to that spot where that line from the sensor goes to any one else recommend any other spots I should check for ash other than where the igniter is and the esp exhaust and auger opening plate I cleaned all them spots and the small door where the exhaust air goes out from the hot water exchanger Let me know if you guys have ever cleaned any other spots I will cleaned the sensor line tomorrow and keep you guys posted.

Similar threads

- Replies

- 10

- Views

- 511

- Replies

- 0

- Views

- 93

- Replies

- 14

- Views

- 1K

- Replies

- 1

- Views

- 416