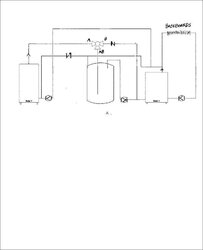

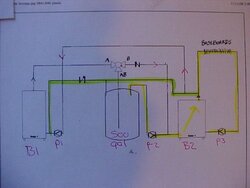

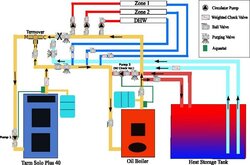

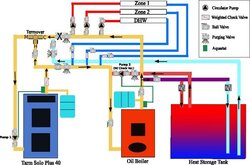

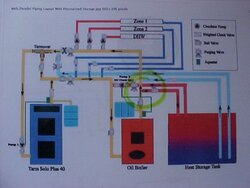

I've bugged nofossil long enough, it's time I try to post this diagram on this forum to get other opinions. I have a TarmSolo40 piped parallel to an oil boiler. I also have an indirect superstor water heater piped to its own zone off that oil boiler. Tarm shows this piping layout on page 20 of their installation manual. It is their preferred layout. Unfortunately all their storage drawings seem to show storage with their primary/secondary set-up. I'd prefer not to alter any of my existing piping if possible. I'd like to add a 500 gallon propane tank for pressurized storage. I may add another in the future if needed.

Using a 3-way zone valve e.g. honewell VC series: All circulators are taco 007

Heating Zone or SuperStor calls for heat:

Port B on zone valve closes, AB opens sending HW to oil boiler. HW goes through oil boiler to heating zones or superstor.

Oil Boiler satisfied, Tarm hot:

Storage tank charges.

port AB closes, B opens wood boiler HW circulates through storage. The Tarm will always pump hot water to storage whenever the oil boiler is satisfied and the wood boiler is operating at 160 degrees or more.

Wood boiler cold, storage hot, oil boiler zone or indirect water heater calls for heat:

HW is circulated through storage to oil boiler.

Tarm cold, Storage cold, zones call for heat:

Oil burner kicks on (oh no!)

I know this idea needs alot of work. I'd really like to hear some comments. This piping layout can be very simply adapted to my basic no storage parallel set-up.

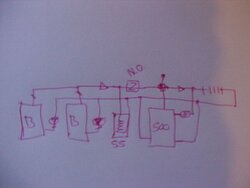

Using a 3-way zone valve e.g. honewell VC series: All circulators are taco 007

Heating Zone or SuperStor calls for heat:

Port B on zone valve closes, AB opens sending HW to oil boiler. HW goes through oil boiler to heating zones or superstor.

Oil Boiler satisfied, Tarm hot:

Storage tank charges.

port AB closes, B opens wood boiler HW circulates through storage. The Tarm will always pump hot water to storage whenever the oil boiler is satisfied and the wood boiler is operating at 160 degrees or more.

Wood boiler cold, storage hot, oil boiler zone or indirect water heater calls for heat:

HW is circulated through storage to oil boiler.

Tarm cold, Storage cold, zones call for heat:

Oil burner kicks on (oh no!)

I know this idea needs alot of work. I'd really like to hear some comments. This piping layout can be very simply adapted to my basic no storage parallel set-up.