I've been burning for 2 years on my Englander and it's great but burns too fast. I can load it up with with hardwoods and once it gets going I put damper down to zero and it still burns through quickly - no lazy flames, constant fast wind-like burning of the coals and logs from the front dog-house where the air enters the box. I have a very tall chimney (old 2 story house, high pitched roof, not sure of exact size), and I've never had a problem with draft, even when it smokes early on. Always goes up right up. There is a large air intake hole in the back of the unit. I don't have any fan on it and it's just getting inside air (not hooked up to outside air connection). I feel that with the tall chimney the draft is just so strong that it can't stop pulling in too much air even with closed damper, resulting in a fast burn and using too much wood. I should also mention that I do not have a block plate above the stove - I lose some heat up into the chimney which probably helps with the draft but I hear that having a warm chimney/liner can help reduce creosote. (maybe?).

I spoke with England's support and they said that it could be getting too much air and I could try covering a portion of the air intake hole. I covered about 1/2 of it with 3M high heat tape and It improved it slightly, but it still burns too quickly - need to refill wood after 2-3 hours. But it definitely helped some - I now see those slower "lazy" flames that I didn't see before. I still register high temps on the thermometer but it's not blazing as hot as it was before - room seems to not get as hot as it did before. It would really blast heat before (maybe too hot), but for that shortened period. Now I'm thinking about covering the hole more - maybe up to 3/4 covered to see if I can extend the burn some more.

Questions:

- has anybody done this before on an Englander or another unit that was getting too much air?

- is closing off a portion of the air intake better or worse than installing a damper in the chimney pipe just above the stove (it's tucked in a fireplace so I only have about 6-8 inches of vertical space above the stove to work with)

- what might be some adverse affects of covering up as much as 3/4 of the way?

- any other ideas? I don't want to see my bucking/chopping/stacking/drying/storing (and of course restacking when it doesn't look nice) go to waste!!

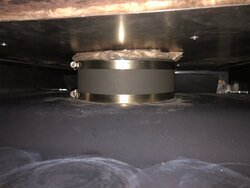

- should I install a block plate? like this.

I spoke with England's support and they said that it could be getting too much air and I could try covering a portion of the air intake hole. I covered about 1/2 of it with 3M high heat tape and It improved it slightly, but it still burns too quickly - need to refill wood after 2-3 hours. But it definitely helped some - I now see those slower "lazy" flames that I didn't see before. I still register high temps on the thermometer but it's not blazing as hot as it was before - room seems to not get as hot as it did before. It would really blast heat before (maybe too hot), but for that shortened period. Now I'm thinking about covering the hole more - maybe up to 3/4 covered to see if I can extend the burn some more.

Questions:

- has anybody done this before on an Englander or another unit that was getting too much air?

- is closing off a portion of the air intake better or worse than installing a damper in the chimney pipe just above the stove (it's tucked in a fireplace so I only have about 6-8 inches of vertical space above the stove to work with)

- what might be some adverse affects of covering up as much as 3/4 of the way?

- any other ideas? I don't want to see my bucking/chopping/stacking/drying/storing (and of course restacking when it doesn't look nice) go to waste!!

- should I install a block plate? like this.

Attachments

Last edited: