Hello all,

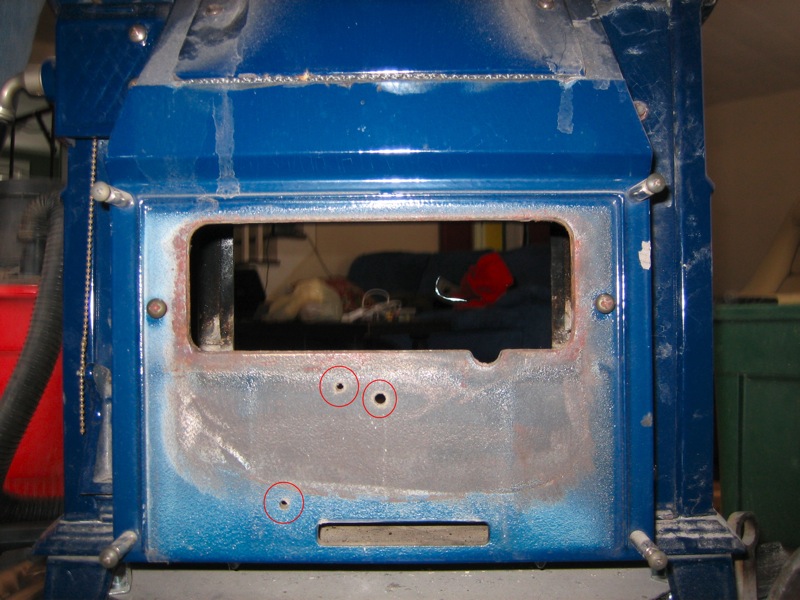

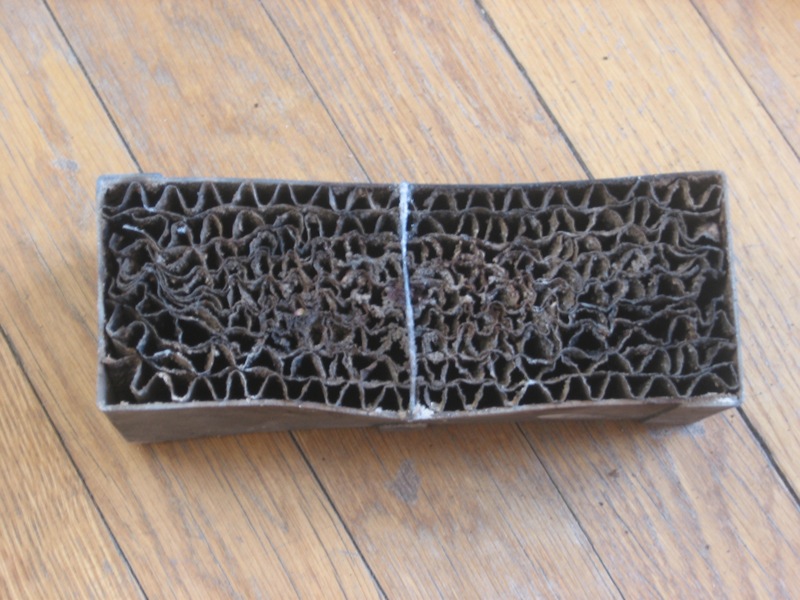

We have been having airflow problems with the stove when it's "closed" (catalytic), so with this warm spell up here in central NY, I spent today taking apart the 1303 intrepid at my girlfriends house (a stove bought refurbished by a reputable local dealer in 2008, before we knew each other). I was taking it apart to install a new seal kit we bought today and check on the cat. Despite finding that the cat was not only clogged, but rather warped and that the refractory chamber was cracked and broke into three pieces on top of the two doors. We have since ordered a new cat and refractory chamber.

Here's the rub though:

After taking most of the stove apart (can post pics in the morning, no camera here) I found that there is not a single part of the secondary air system. Just an open slot under the back plate which the stove/EPA info is riveted to.

We've already spent $350 on this thing today, and would prefer to just leave it, but the question presents itself:

How many hassles are we looking at by not having a secondary air system, and just leaving an open slot there?

The opening in the back flows into a slot formed at the base of the refractory chamber by the two ribs it sits on lifting it off of the stove floor. It's a little tough to visualize what happens after it clears the refractory chamber.

What does the secondary air inlet actually do? Keep ash off the cat/r. chamber? Found a crapton of fine ash in there today.

OH, and I have a hunch that the refractory chamber isn't necessarily the one for the 1303 (it has access doors on both the front and back of the refractory chamber. (again, can post pics tomorrow).

Edit: I'm getting the info about the secondary air stuff from here. I know that this is the model #1990, but the item numbers for parts number 27-32 cross and this schematic is a lot clearer.

Edit2: Could I just buy the flap for $15.25 + shipping and wedge it shut? That's gotta be better than it being open all the time.

We have been having airflow problems with the stove when it's "closed" (catalytic), so with this warm spell up here in central NY, I spent today taking apart the 1303 intrepid at my girlfriends house (a stove bought refurbished by a reputable local dealer in 2008, before we knew each other). I was taking it apart to install a new seal kit we bought today and check on the cat. Despite finding that the cat was not only clogged, but rather warped and that the refractory chamber was cracked and broke into three pieces on top of the two doors. We have since ordered a new cat and refractory chamber.

Here's the rub though:

After taking most of the stove apart (can post pics in the morning, no camera here) I found that there is not a single part of the secondary air system. Just an open slot under the back plate which the stove/EPA info is riveted to.

We've already spent $350 on this thing today, and would prefer to just leave it, but the question presents itself:

How many hassles are we looking at by not having a secondary air system, and just leaving an open slot there?

The opening in the back flows into a slot formed at the base of the refractory chamber by the two ribs it sits on lifting it off of the stove floor. It's a little tough to visualize what happens after it clears the refractory chamber.

What does the secondary air inlet actually do? Keep ash off the cat/r. chamber? Found a crapton of fine ash in there today.

OH, and I have a hunch that the refractory chamber isn't necessarily the one for the 1303 (it has access doors on both the front and back of the refractory chamber. (again, can post pics tomorrow).

Edit: I'm getting the info about the secondary air stuff from here. I know that this is the model #1990, but the item numbers for parts number 27-32 cross and this schematic is a lot clearer.

Edit2: Could I just buy the flap for $15.25 + shipping and wedge it shut? That's gotta be better than it being open all the time.