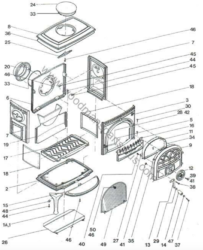

Just bought a second hand stove and found a few issues i wonder if someone could offer advice.

1 Something looks like it has cracked and broken away on the inside at the base of the stove at the rear can this be repaired?

2 Crack in lid could these cause carbon monoxide issues?

How can i repair this?

1 Something looks like it has cracked and broken away on the inside at the base of the stove at the rear can this be repaired?

2 Crack in lid could these cause carbon monoxide issues?

How can i repair this?

although it only cost me $100, guy never mentioned it wasn't complete or had bits missing.

although it only cost me $100, guy never mentioned it wasn't complete or had bits missing.