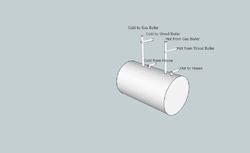

I've read until I think I know what to do, to the point of thoroughly confused. I'm not a hvac or plumber, but seem to muddle my way through ok. I'm going to try to attach a Google Sketch-up image of what I want to do, along the lines of the Simplest Storage Design. I will have one circulator each for the gas boiler, wood boiler, and house heating loops, (three total with one circulator and three zone valves (existing). I understand the near boiler piping well, and will do all of that as well. The gas boiler is existing, quite old, but works ok, and hopefully will be used very little. The wood boiler is a Biomass 40. Storage is 500 gallons, the most I could fit in the space. The gas boiler is in another basement 40' away from the wood boiler. The storage is next to the wood boiler. I am planning 2" black iron welded into the tank, reduced to 1-1/4" piping to the wood boiler.

I sure would appreciate any advice before I get fully underway. Again, I'm not totally incompetent, but build construction and farming are more my thing. (Feel free to pick my brain on those!)

Thanks in advance for your time,

Bill

I sure would appreciate any advice before I get fully underway. Again, I'm not totally incompetent, but build construction and farming are more my thing. (Feel free to pick my brain on those!)

Thanks in advance for your time,

Bill