I have a Ecnoburn and 500gal of pressurized storage. If the house is calling for heat, the tank does not charge and vise versa. I have a danfoss valve that prevents cold water to return to the boiler. The problem I have is that the house can be satisfied with heat (thus storage is charging) but it takes forever for the storage to charge because the danfoss restricts flow back to the boiler until the tank water reaches 140. The boiler will actually sit idle because of this thus reducing efficientcy. What am I doing wrong here?

Storage taking too long to charge. Any ideas???

- Thread starter eriesigtau

- Start date

-

Active since 1995, Hearth.com is THE place on the internet for free information and advice about wood stoves, pellet stoves and other energy saving equipment.

We strive to provide opinions, articles, discussions and history related to Hearth Products and in a more general sense, energy issues.

We promote the EFFICIENT, RESPONSIBLE, CLEAN and SAFE use of all fuels, whether renewable or fossil. -

Super Cedar firestarters 30% discount Use code Hearth2024 Click here

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

- Status

- Not open for further replies.

Are you saying that the boiler goes into idle mode because of the restriction?

My initial guess is to move more water.

But that is a guess without description of piping size, pump size, boiler size, bypass for Danfoss? Boiler start temp?

gg

My initial guess is to move more water.

But that is a guess without description of piping size, pump size, boiler size, bypass for Danfoss? Boiler start temp?

gg

eriesigtau said:I have a Ecnoburn and 500gal of pressurized storage. If the house is calling for heat, the tank does not charge and vise versa. I have a danfoss valve that prevents cold water to return to the boiler. The problem I have is that the house can be satisfied with heat (thus storage is charging) but it takes forever for the storage to charge because the danfoss restricts flow back to the boiler until the tank water reaches 140. The boiler will actually sit idle because of this thus reducing efficientcy. What am I doing wrong here?

Also need to know how tank is plumbed? How is return water from house moving through the Danfoss?

gg

The Danfoss is protecting the boiler. If you have your circulator set for 170F launch temp, then if your return water is 110F, you will be getting 50% of your flow to the house/storage and 50% to mix with the incoming return water. When the return is 120 it is 60/40; 130 it is 75/25; at 140 it is 100%. What is your bottom of tank return temp?

Im a tard... I was messing around with that gate valve last year and it was only about 1/4 open. It's now wide open. We will see what happens now..haha

Well, This morning have have 180 water returning to the boiler from the danfoss and 160 water going into the danfoss from the house. The tank is not hot yet. It was about 15deg last night so its possible the house was calling for heat too much of the time. The blower on the boiler is on its slowest setting right now with a good bed of coals. I just wish there was a way to set up the system so the boiler ran as hard as it could until the tank was charged even if the house was calling for heat most of the time. Any ideas?

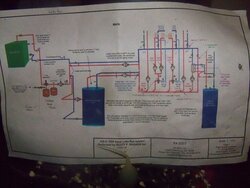

We could all draw schematics by studying the photo, hope we got it right, and go from there.eriesigtau said:Any ideas?

But instead could you post the schematic you used to design the system and verify that it's true to what was installed?

Then we can all refer to a common drawing that stands a better chance of representing the system.

--ewd

Do you have a ball valve on your bypass loop going to the Danfoss? If so (and you should) it should be closed down until it's maybe 20% open, max. This will allow you to force more supply to the system.

Also, it's sometimes helpful to run for a day or so to get your tank up to temp before you heat the house. Getting all of your storage up to temp will take some work. Especially if the tank returns are room temp.

Also, it's sometimes helpful to run for a day or so to get your tank up to temp before you heat the house. Getting all of your storage up to temp will take some work. Especially if the tank returns are room temp.

If you post a schematic diagram of piping layout include everything like pipe size, reducers etc.. This can be critical in pumping heat away from the boiler.

Yep close it down some or you will cause your boiler to go to idle when your tanks are still not up to temp.

Rob

Rob

the schematic doesnt show the danfoss but its there as you can see in the pic and everything else is about the same. I used a larger expansion tank than what he sized. Plus I don't use the cold water return between the tank and the manafold. I was getting a ciphoning effect when that was in use. I just shut the valve off. The water can still get back to the storage through the other manafold return.

When the house calls for heat and boiler water in the primary loop is over 165, the manafold pulls water from the primary loop. If the house is not calling for heat and the primary loop is over 165, then the tank charges. If the boiler is off and house calls from heat, its pulling from the tank regardless of tank temp.

When the house calls for heat and boiler water in the primary loop is over 165, the manafold pulls water from the primary loop. If the house is not calling for heat and the primary loop is over 165, then the tank charges. If the boiler is off and house calls from heat, its pulling from the tank regardless of tank temp.

Attachments

So when I had the gate valve at 25%... it was right? My manafold is hot even when the bypass is wide open. I think my real problem is the boiler idles too much and the tank never gets a chance to charge.

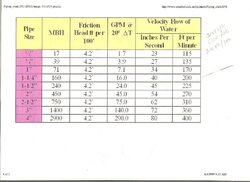

Your 150 calls for 1.25" minimum piping at stove. In your picture the pipes look small and the engineering diagram you posted seems to call for 1" piping.

There are many things that can affect your idling situation. That is why it important to draw YOUR layout with all part's included.

I had the same situation. It ended up that the stove that I bought pre-plumbed at stove, was plumbed with the wrong Grundfos Pump. So, even experts make mistakes.

With piping you can see the difference between 1" and 1.25" for BTU capacity. Then you need to add 45's, 90's, tee's and the like and all those fittings have a negative impact on your ability to carry away heat. If you can't move heat to storage you boiler will idle.

Rob

There are many things that can affect your idling situation. That is why it important to draw YOUR layout with all part's included.

I had the same situation. It ended up that the stove that I bought pre-plumbed at stove, was plumbed with the wrong Grundfos Pump. So, even experts make mistakes.

With piping you can see the difference between 1" and 1.25" for BTU capacity. Then you need to add 45's, 90's, tee's and the like and all those fittings have a negative impact on your ability to carry away heat. If you can't move heat to storage you boiler will idle.

Rob

Attachments

The engineer who designed it had no experience with storage or gassification boilers. I wanted to put 1-1/4 pipe on the primary but he didn't think I would need it. Its burried now so there not much I can do unless I dig it up and replace.

It sounds to me that my best hope is to play with that gate valve when the storage is charging and try to set it where the danfoss is allowing water to flow back to the boiler more often.

It sounds to me that my best hope is to play with that gate valve when the storage is charging and try to set it where the danfoss is allowing water to flow back to the boiler more often.

maple1

Minister of Fire

eriesigtau said:So when I had the gate valve at 25%... it was right? My manafold is hot even when the bypass is wide open. I think my real problem is the boiler idles too much and the tank never gets a chance to charge.

If the tank is cold the boiler should not idle. You may have some idling as storage reaches set point temp but when it has cold return water it should run on high burn. I had that problem initially and it was due to not moving enough gpm, combination of ball valve for Danfoss not open enough and pump on too slow of speed.

Gg

goosegunner... is your system like mine or is it setup a different way. ie... if the house is calling, the tank will not charge? If its different please explain the difference.

Have a look at the 'Simplest' sticky, or the Tarm reference designs, or the Laddomat reference designs.

Hot water from wood boiler goes directly to top of storage. Load line can tee into the line coming from the wood boiler or it can pull from the top of storage, either way. Load gets first shot at any hot water from boiler, any excess goes to storage. If boiler flow is insufficient then deficit comes from storage.

Lines to boiler may be marginally sized, but even at 6 gpm you should be able to get up to 150000 btu per hour or more if the return line to the boiler comes from the bottom of storage and nowhere else, but you can't make that happen the way you're set up. Sorry, but that whole primary boiler loop strategy has to go.

Hot water from wood boiler goes directly to top of storage. Load line can tee into the line coming from the wood boiler or it can pull from the top of storage, either way. Load gets first shot at any hot water from boiler, any excess goes to storage. If boiler flow is insufficient then deficit comes from storage.

Lines to boiler may be marginally sized, but even at 6 gpm you should be able to get up to 150000 btu per hour or more if the return line to the boiler comes from the bottom of storage and nowhere else, but you can't make that happen the way you're set up. Sorry, but that whole primary boiler loop strategy has to go.

Is the primary circulator on the correct side of the mixing valve ? Shouldn't the water be pulled through the mixing valve ? Are the Danfoss different than the Tremovar ?

Also which cold water return do you have shut off ? With this shut off are you getting pumping spread between your inlet and outlet inside your tank ( end to end or top to bottom ) ? Or is it just bridging in the top of the tank with out stratifying ?

Also which cold water return do you have shut off ? With this shut off are you getting pumping spread between your inlet and outlet inside your tank ( end to end or top to bottom ) ? Or is it just bridging in the top of the tank with out stratifying ?

eriesigtau said:goosegunner... is your system like mine or is it setup a different way. ie... if the house is calling, the tank will not charge? If its different please explain the difference.

Mine is pipe like the Simple pressurized storage sticky. It all likelihood some flow goes to storage some goes to the load.

I have considered repiping mine and taking the load off one end of the tank and charge the tank with boiler on opposite end. That way the boiler can just run and not go up and down. At times the return from the house will actually cool the boiler several degrees when it kicks in depending on where in the burn the wood load is.

gg

eriesigtau said:Here it is... hopfully you can read the descriptions.

Can you re label the pic so we can read the print? I think you have a plumbing problem but i cant read what is what?

Rob

Ok I saved the pic in picasa and zoomed in on the pic.......I take it your boiler is not in the same room as your tank? That danfos should be right at your boiler along with your pump. The bypass should have a gate/ball valve so some of the water in the boiler can circulate around the bypass loop aver the thermostat in danfos and mix with return water to keep the return water above 140*. I have a eko but if you look at my blog you will see a pic of how it should look at your boiler. I am just guessing this is your problem based off your pic......give us more info on your set up.

Rob

Rob

The boiler sits in a leanto behind my garage. The pic I took is my storage and it in my basement. There are no circs at the boiler. The only thing between the boiler and the storage is my expansion tank. Why does the danfoss need to be right at the boiler? Basically, all there is between the boiler and the valve is 50ft of pipe. My pump does push into the danfoss and not away.

- Status

- Not open for further replies.

Similar threads

- Replies

- 0

- Views

- 378

- Replies

- 10

- Views

- 3K

- Replies

- 0

- Views

- 1K

- Replies

- 4

- Views

- 969