my pellet stove has to my knowledge no air/fuel settings i have seen on it..on certain days when the wind is blowing right into the oak it burns better with lots of air flow and this got me thinking..has anybody ever put a small fan bower on the oak to increase the air flow ..my flame is always lazy orange and never sparks like most of yall stoves do.....just a thought...anybody wanna chime in on this one?

a few ??'s

- Thread starter burrman

- Start date

-

Active since 1995, Hearth.com is THE place on the internet for free information and advice about wood stoves, pellet stoves and other energy saving equipment.

We strive to provide opinions, articles, discussions and history related to Hearth Products and in a more general sense, energy issues.

We promote the EFFICIENT, RESPONSIBLE, CLEAN and SAFE use of all fuels, whether renewable or fossil.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

- Status

- Not open for further replies.

jtakeman

Minister of Fire

it does a little but my flame is still lazy very sooty flame..my glass takes 2 hours to soot up from clean im trying a trial run with a blower on the oak its roaring now  !..before i would have clumps and such in burn pot now im actually getting sparky's which is telling me im getting a more complete burn

!..before i would have clumps and such in burn pot now im actually getting sparky's which is telling me im getting a more complete burn

!..before i would have clumps and such in burn pot now im actually getting sparky's which is telling me im getting a more complete burn

!..before i would have clumps and such in burn pot now im actually getting sparky's which is telling me im getting a more complete burnjtakeman

Minister of Fire

There needs to be a balance. Too much air and you could push too much heat up the vent pipe. Can you adjust the added blower speed? If so use as little extra air as possible.

Are you completely sure the stove is clean, Especially the blower housing?

Are you completely sure the stove is clean, Especially the blower housing?

SmokeyTheBear

Minister of Fire

Could you describe how you clean that unit and please describe the venting starting at the exhaust port on the stove.

Are there any kinks or ups and downs in the OAK and how is it wind shielded on the outside?

Is it possible that you have something inside the OAK and how long is it?

Are there any kinks or ups and downs in the OAK and how is it wind shielded on the outside?

Is it possible that you have something inside the OAK and how long is it?

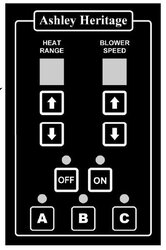

im going to do a complete clean in the afternoon tomorrow.. and no i cannot adjust the oak blower speed... if i just run the stove by its self..the flame looks similar to a candle burning..very lazy...i dunno on this stove ..i run it on heat setting 1 and blower setting 3 and it cooks i cant imagine it on setting 5 lol

have you ever heard of anyone doing this to their oak? there is no damper or anything on my oak it goes from the burn pot straight out the back to the collar to the pvc pipe out the wall to the outside...this stove has never burned right it has always been a lazy burner ..i think thats why my glass gets so sooty and on setting 1 and 3 my 1 bag burn time is like 12 hours..my brother in law has a pellet stove and he can burn on a bag for like 2 1/2 days on low

have you ever heard of anyone doing this to their oak? there is no damper or anything on my oak it goes from the burn pot straight out the back to the collar to the pvc pipe out the wall to the outside...this stove has never burned right it has always been a lazy burner ..i think thats why my glass gets so sooty and on setting 1 and 3 my 1 bag burn time is like 12 hours..my brother in law has a pellet stove and he can burn on a bag for like 2 1/2 days on low

SmokeyTheBear

Minister of Fire

I've heard of people thinking about doing that.

It isn't really what you should be doing as any kind of long term thing.

Was the stove brand new when you got it or was it used?

During start up does the stove cycle through all of its heat levels and if so does the flame grow as it goes up and finally shrink to the selected heat level?

Is any ash scrapper properly positioned for burning?

Have you conducted the dollar bill gasket test, for both the firebox door and the ash pan door?

Can you post pictures? If so would you post a picture of your burn pot both from the top and from the bottom.

ETA: Is there a restrictor plate in the hopper?

It isn't really what you should be doing as any kind of long term thing.

Was the stove brand new when you got it or was it used?

During start up does the stove cycle through all of its heat levels and if so does the flame grow as it goes up and finally shrink to the selected heat level?

Is any ash scrapper properly positioned for burning?

Have you conducted the dollar bill gasket test, for both the firebox door and the ash pan door?

Can you post pictures? If so would you post a picture of your burn pot both from the top and from the bottom.

ETA: Is there a restrictor plate in the hopper?

first picture is how it sits ..second picture is how its piped out..it comes out of stove and then 45's then out and upburrman said:

third picture is what i get after burning a bag ...to me it seems that they are not burned complete

PLEASE NOTE THESE PICS ARE OLD I NOW HAVE A PAD UNDERNEATH UNIT

!!I DONT WANNA GO THREW THAT AGAIN ON HERE..LOL

!!I DONT WANNA GO THREW THAT AGAIN ON HERE..LOLSmokeyTheBear

Minister of Fire

SmokeyTheBear

Minister of Fire

Oh did we sort of beat you up over the lack of a pad?

Good, you see we don't want to see folks get hurt.

Good, you see we don't want to see folks get hurt.

stove was used when i got it..SmokeyTheBear said:I've heard of people thinking about doing that.

It isn't really what you should be doing as any kind of long term thing.

Was the stove brand new when you got it or was it used?

During start up does the stove cycle through all of its heat levels and if so does the flame grow as it goes up and finally shrink to the selected heat level?

Is any ash scrapper properly positioned for burning?

Have you conducted the dollar bill gasket test, for both the firebox door and the ash pan door?

Can you post pictures? If so would you past a picture of your burn pot both from the top and from the bottom.

ETA: Is there a restrictor plate in the hopper?

i manually start the stove..always did and so did the previous owner.it has a starter on it but i dont think it works..my flame is usually about a foot high but very lazy..now with the blower it roars and actually burns good

have not done a dollar bill test on it...

"Is any ash scrapper properly positioned for burning?" kinda lost on this one

no restrictor plate in hopper

please explain i guess...SmokeyTheBear said:That doesn't look like a proper vertical pipe run termination.

i had it just ran out the house then it got my house dirty so i put the rest of the pipe i had on it this is the old way i had it

jtakeman

Minister of Fire

I remember the stove and the flack you recieved on the pad. But we just want things safe. I think smokey noticed the 4 inch pipe that was reduced to 3 inch. It's not recommended as it will effect the draft on the stove. I would try removing the 3 inch add on and see if it burns better after you clean the h@ll out of the stove. Don't forget the exhaust blower and housing.

Keep us posted.

Keep us posted.

Hello

The Lazy fire means there is not enough air going into the burn pot.

Items to check or try

1. Increase the size of the OAK piping. Looks like 2" increase to 3"

2. Check the combustion blower to make sure it is working up to capacity. Mine is 165 CFM, find out what yours should be.

3. Increase the speed of the combustion fan or open any air restrictor more if possible.

4. Assure stove is clean and OAK is not clogged. Put a shop vac in blower mode thru it as a test.

Hope this helps

Good luck and let us know how it works.

The Lazy fire means there is not enough air going into the burn pot.

Items to check or try

1. Increase the size of the OAK piping. Looks like 2" increase to 3"

2. Check the combustion blower to make sure it is working up to capacity. Mine is 165 CFM, find out what yours should be.

3. Increase the speed of the combustion fan or open any air restrictor more if possible.

4. Assure stove is clean and OAK is not clogged. Put a shop vac in blower mode thru it as a test.

Hope this helps

Good luck and let us know how it works.

SmokeyTheBear

Minister of Fire

No, I noticed the horizontal termination of the vertical stack.

That can raise havoc with the venting system and cause the stove to burn well sometime and not other times, depending upon the winds at the time.

Jay, you know where I'm going here.

We have know idea of which of the many reasons for the poor burn to start with but it is certain that there is an airflow issue and everything that is incorrect about the venting system and that includes the OAK needs to be taken care of first.

Then the stove and venting needs to be really cleaned, that means you have to find the ash traps remove their covers etc .....

Is there a manual on line for the stove?

Flame is usually judged by color, you need to understand that this is a balancing act and there is actually a range that can be acceptable. Lazy flames are out, black tips aren't allowed but neither is a blowtorch. There should be a hint of blue just above the pellets and the color in the yellow/orange range tending towards yellow, the pellets should be wiggling from time to time. There should be fly ash embers blowing off (more so on the top feeders as they eject these when the pellets fall into the burn pot).

I'm out of here for a bit.

Make certain you have a gasket for the combustion blower as that puppy needs to have its motor and fan assembly removed and cleaned along with the cavity it sits in.

I'll download a manual if I can find one and talk to you tomorrow.

That can raise havoc with the venting system and cause the stove to burn well sometime and not other times, depending upon the winds at the time.

Jay, you know where I'm going here.

We have know idea of which of the many reasons for the poor burn to start with but it is certain that there is an airflow issue and everything that is incorrect about the venting system and that includes the OAK needs to be taken care of first.

Then the stove and venting needs to be really cleaned, that means you have to find the ash traps remove their covers etc .....

Is there a manual on line for the stove?

Flame is usually judged by color, you need to understand that this is a balancing act and there is actually a range that can be acceptable. Lazy flames are out, black tips aren't allowed but neither is a blowtorch. There should be a hint of blue just above the pellets and the color in the yellow/orange range tending towards yellow, the pellets should be wiggling from time to time. There should be fly ash embers blowing off (more so on the top feeders as they eject these when the pellets fall into the burn pot).

I'm out of here for a bit.

Make certain you have a gasket for the combustion blower as that puppy needs to have its motor and fan assembly removed and cleaned along with the cavity it sits in.

I'll download a manual if I can find one and talk to you tomorrow.

SmokeyTheBear

Minister of Fire

Don2222 said:Hello

The Lazy fire means there is not enough air going into the burn pot.

Items to check or try

1. Increase the size of the OAK piping. Looks like 2" increase to 3"

2. Check the combustion blower to make sure it is working up to capacity. Mine is 165 CFM, find out what yours should be.

3. Increase the speed of the combustion fan or open any air restrictor more if possible.

4. Assure stove is clean and OAK is not clogged. Put a shop vac in blower mode thru it as a test.

Hope this helps

Good luck and let us know how it works.

I sure as h*ll hope you don't have a 165 CFM combustion blower, they aren't close to that on a pellet stove.

but the oak fitting into the stove is only like 1 3/4...Don2222 said:Hello

The Lazy fire means there is not enough air going into the burn pot.

Items to check or try

1. Increase the size of the OAK piping. Looks like 2" increase to 3"

2. Check the combustion blower to make sure it is working up to capacity. Mine is 165 CFM, find out what yours should be.

3. Increase the speed of the combustion fan or open any air restrictor more if possible.

4. Assure stove is clean and OAK is not clogged. Put a shop vac in blower mode thru it as a test.

Hope this helps

Good luck and let us know how it works.

i had the blower fan on the highest setting and it was the same flame..no air restrictions on it oak is all open

going to clean tomorrow but it don't help the flame its always lazy

ill report after i do a deep clean

ill report after i do a deep clean

I

imacman

Guest

j-takeman said:.....I think smokey noticed the 4 inch pipe that was reduced to 3 inch. It's not recommended as it will effect the draft on the stove. I would try removing the 3 inch add on and see if it burns better after you clean the h@ll out of the stove. Don't forget the exhaust blower and housing.

Keep us posted.

I agree with jay. The stove probably needs a "tear it down" cleaning, and that 4" to 3" pipe is just choking the stove. The cap is wrong for a vertical pipe....it's supposed to be a round cap.

jtakeman

Minister of Fire

SmokeyTheBear said:Don2222 said:Hello

The Lazy fire means there is not enough air going into the burn pot.

Items to check or try

1. Increase the size of the OAK piping. Looks like 2" increase to 3"

2. Check the combustion blower to make sure it is working up to capacity. Mine is 165 CFM, find out what yours should be.

3. Increase the speed of the combustion fan or open any air restrictor more if possible.

4. Assure stove is clean and OAK is not clogged. Put a shop vac in blower mode thru it as a test.

Hope this helps

Good luck and let us know how it works.

I sure as h*ll hope you don't have a 165 CFM combustion blower, they aren't close to that on a pellet stove.

I agree, The convection blower might be that. But the combustion is only about half that. My beast only has only about 85 CFM combustion blower. Largest I have seen on a stove is 105 CFM. Except for the big BTU furnaces you wont see much more.

jtakeman

Minister of Fire

SmokeyTheBear said:No, I noticed the horizontal termination of the vertical stack.

That can raise havoc with the venting system and cause the stove to burn well sometime and not other times, depending upon the winds at the time.

Jay, you know where I'm going here.

I see that now smokey, A horizontal cap on a vertical pipe is nothing but a wind scoop. Get the breeze going the right direction and it could stop all exhaust flow. Sure hope the OP has a CO detector!

I see pellet pipe on eBay all the time and can be scored real cheap. Also flee markets and tag sales can get you bits and pieces.

Can you discribe you before season cleaning ethics?

- Status

- Not open for further replies.

Similar threads

- Replies

- 1

- Views

- 825

- Replies

- 1

- Views

- 500

- Replies

- 3

- Views

- 2K

- Replies

- 0

- Views

- 598