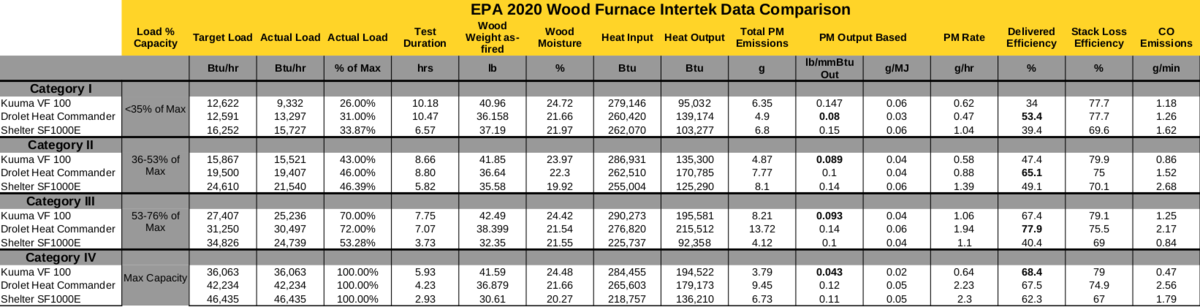

I made up a quick reference comparing the main EPA hot air furnaces in the category by combining the tables from three furnaces. I did this so I could see where I wanted to put the most effort in when building my furnace controller and furnace shed project. I thought it might be useful for others to have all that data in one spot as well, so I made a screenshot of the spreadsheet.

It all looks as you'd expect for the most part. There are two anomalies on the Cat 3 burns that stand out. The first, on the Drolet, it has a higher delivered efficiency than stack loss (overall) efficiency, which I would not think possible, it seems implausibly high. I can't really explain how that happened, but it stands out, anyway. The second, on the Shelter, the Cat 3 delivered efficiency looks implausibly low relative to the other 3 tests. Normally, you'd expect a rising rate of delivered efficiency as burn rate increases, since the blower runs more often. On the Shelter, I'm guessing it is due to the poor controls. To hit burn rate, they leave the thermostat off until it falls below the target load rate, and at that point, the fire is burned too low to recover, which is probably why they only hit 53% of actual instead of the 75% target load- once the fire burns on low for that long, it's too cold to recover in time in that furnace. This is borne out by the equally implausibly low CO emissions for that test - the furnace was mainly coaling instead of burning for the last half if I had to guess.

The other thing that stands out is the Drolet achieves !!incredible!! delivered efficiency at the lower burn rates in particular. Stack loss is close (but not as good) as the Kuuma, but they are getting more heat out the plenum and less is being radiated. Doubly surprising given the firebox window... I think they must have done some fancy insulation work to make this happen. Kuuma is king of the overall burn emissions in general, although they suffer at the lowest burn rates - I think this is because they are able to burn at lower rates than anyone else in general, and delivered efficiency out the plenum just drops like a rock at the low BTU outputs (stack loss is still excellent of course). If they had burned to match the higher demand % of the others, they'd probably posted better overall numbers on that test. Keep in mind the differences in the delivered there, it's not majorly important in practice.

Attached a PDF so the data can be cut/paste more easily if needed. Linked the Intertek test PDFs, too big to attach. Drolet has several invalidated test failures, so you need to be careful when parsing that file, as some of the results are not passing test results, I picked the passing results for the table. Shelter data is from the most recent Oct. 2020 retests.

Kuuma Vapor Fire 100 Report

Drolet Heat Commander Report

Shelter SF1000E Report

These are nice guides, but not the end-all be-all. For one, they use HHV, which is basically sandbagging the achieved efficiency, because it pretends that wood moisture doesn't exist or that it's the furnace' fault... The LHV which is more realistic IMO comparing equipment to equipment, like for like brings all the posted numbers closer together - the real world differences are even smaller than they appear here.

It all looks as you'd expect for the most part. There are two anomalies on the Cat 3 burns that stand out. The first, on the Drolet, it has a higher delivered efficiency than stack loss (overall) efficiency, which I would not think possible, it seems implausibly high. I can't really explain how that happened, but it stands out, anyway. The second, on the Shelter, the Cat 3 delivered efficiency looks implausibly low relative to the other 3 tests. Normally, you'd expect a rising rate of delivered efficiency as burn rate increases, since the blower runs more often. On the Shelter, I'm guessing it is due to the poor controls. To hit burn rate, they leave the thermostat off until it falls below the target load rate, and at that point, the fire is burned too low to recover, which is probably why they only hit 53% of actual instead of the 75% target load- once the fire burns on low for that long, it's too cold to recover in time in that furnace. This is borne out by the equally implausibly low CO emissions for that test - the furnace was mainly coaling instead of burning for the last half if I had to guess.

The other thing that stands out is the Drolet achieves !!incredible!! delivered efficiency at the lower burn rates in particular. Stack loss is close (but not as good) as the Kuuma, but they are getting more heat out the plenum and less is being radiated. Doubly surprising given the firebox window... I think they must have done some fancy insulation work to make this happen. Kuuma is king of the overall burn emissions in general, although they suffer at the lowest burn rates - I think this is because they are able to burn at lower rates than anyone else in general, and delivered efficiency out the plenum just drops like a rock at the low BTU outputs (stack loss is still excellent of course). If they had burned to match the higher demand % of the others, they'd probably posted better overall numbers on that test. Keep in mind the differences in the delivered there, it's not majorly important in practice.

Attached a PDF so the data can be cut/paste more easily if needed. Linked the Intertek test PDFs, too big to attach. Drolet has several invalidated test failures, so you need to be careful when parsing that file, as some of the results are not passing test results, I picked the passing results for the table. Shelter data is from the most recent Oct. 2020 retests.

Kuuma Vapor Fire 100 Report

Drolet Heat Commander Report

Shelter SF1000E Report

These are nice guides, but not the end-all be-all. For one, they use HHV, which is basically sandbagging the achieved efficiency, because it pretends that wood moisture doesn't exist or that it's the furnace' fault... The LHV which is more realistic IMO comparing equipment to equipment, like for like brings all the posted numbers closer together - the real world differences are even smaller than they appear here.

It's hard to account for delivered heat when the blower is off.

It's hard to account for delivered heat when the blower is off.