Hello All!

I see your wisdom, and general comments, on my proposed piping schematic for my Varmebaronen install.

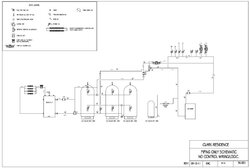

Thanks to skfire from this site, I had a great head start on a schematic. Its based on the Tarm diagrams, tweaked to fit my existing system. The intent is to hook up two zones with capped connections for two future ones, one for heat, one for DHW.

Control will be through the BLT control box tied into my existing Taco zone control.

Im specifically looking to see if anyone thinks I can add/delete any ball valves, drains, temp gauges, etc. Also thinking the expansion tank should be connected to the air scoop, or off of the bottom connection to the tanks. Also need to size the expansion tank, but Im thinking I probably need two of them now....

Im also curious about where the best place for me to measure tank temps would be, or if I need to measure all three tanks, etc.

Thanks in advance.

I see your wisdom, and general comments, on my proposed piping schematic for my Varmebaronen install.

Thanks to skfire from this site, I had a great head start on a schematic. Its based on the Tarm diagrams, tweaked to fit my existing system. The intent is to hook up two zones with capped connections for two future ones, one for heat, one for DHW.

Control will be through the BLT control box tied into my existing Taco zone control.

Im specifically looking to see if anyone thinks I can add/delete any ball valves, drains, temp gauges, etc. Also thinking the expansion tank should be connected to the air scoop, or off of the bottom connection to the tanks. Also need to size the expansion tank, but Im thinking I probably need two of them now....

Im also curious about where the best place for me to measure tank temps would be, or if I need to measure all three tanks, etc.

Thanks in advance.