Hello,

I have been lurking since we moved in to our house 6 years ago. The house had an old Fisher grandpa.

Decided to replace it because the stove and chimney were in bad shape. The local dealer sold me a hearthstone GM 60.

I'm having smoke roll out problems mainly when starting a fire before it takes off. I think this is pretty common with this stove. Once it gets going it works well. I notice it more on wet mild days like today.

I wanted opinions on the minimum flue height. The manual recommends 14' minimum off of the floor. The stove sits up on an elevated hearth, I have low ceilings, and a low roof pitch resulting in about 12' from connector to cap, which gives me 17' from the floor of the house to the cap.

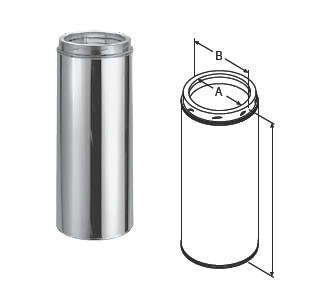

Would I benefit from adding two more feet of chimney? The pipe is not cheap and the chimney is already about 6' above the roof where it goes out so my concern is being able to clean the chimney if it's over my head.

Thanks in advance! I've already learned a lot here!

I have been lurking since we moved in to our house 6 years ago. The house had an old Fisher grandpa.

Decided to replace it because the stove and chimney were in bad shape. The local dealer sold me a hearthstone GM 60.

I'm having smoke roll out problems mainly when starting a fire before it takes off. I think this is pretty common with this stove. Once it gets going it works well. I notice it more on wet mild days like today.

I wanted opinions on the minimum flue height. The manual recommends 14' minimum off of the floor. The stove sits up on an elevated hearth, I have low ceilings, and a low roof pitch resulting in about 12' from connector to cap, which gives me 17' from the floor of the house to the cap.

Would I benefit from adding two more feet of chimney? The pipe is not cheap and the chimney is already about 6' above the roof where it goes out so my concern is being able to clean the chimney if it's over my head.

Thanks in advance! I've already learned a lot here!