I bought a house this past fall that has a Dumont Tempest boiler from 1983. It seems to be in pretty good shape, but it has issues (more detail below). My skills and knowledge are starting from zero, but I have the original manual and a fairly good idea what's wrong. I am looking for any of a variety of types of help with this: information, advice, access to parts, even access to a capable professional service provider. It seems like there must be a few members here with the same boiler.

My basic (immediate) problem is that my circulator isn't running when the boiler is burning. It appears the (end-of-fire?) thermostat or the control logic between it and the circulator isn't working correctly. The blower and circulator are both supposed to run as long as the thermostat stays closed (above 325F). My circulator does not run at all under normal conditions, causing the water to sit in the boiler until it overheats, triggering hi-limit shutoff. When the hi-limit is reached, it shuts down the blower and starts the circulator as expected. So I know the circulator is functional and that some of the control logic is non-functional. The wiring to the thermostat is really old and corroded, so my first thought is to get it rewired. The manual does include a wiring schematic. If that doesn't help, probably the thermostat itself is broken. That's where things get sticky, because I came up totally empty when trying to find that part online.

Anyway, I'm really eager to get this thing running. If there's anyone out there with any useful information, please let me know. Thanks in advance.

My basic (immediate) problem is that my circulator isn't running when the boiler is burning. It appears the (end-of-fire?) thermostat or the control logic between it and the circulator isn't working correctly. The blower and circulator are both supposed to run as long as the thermostat stays closed (above 325F). My circulator does not run at all under normal conditions, causing the water to sit in the boiler until it overheats, triggering hi-limit shutoff. When the hi-limit is reached, it shuts down the blower and starts the circulator as expected. So I know the circulator is functional and that some of the control logic is non-functional. The wiring to the thermostat is really old and corroded, so my first thought is to get it rewired. The manual does include a wiring schematic. If that doesn't help, probably the thermostat itself is broken. That's where things get sticky, because I came up totally empty when trying to find that part online.

Anyway, I'm really eager to get this thing running. If there's anyone out there with any useful information, please let me know. Thanks in advance.

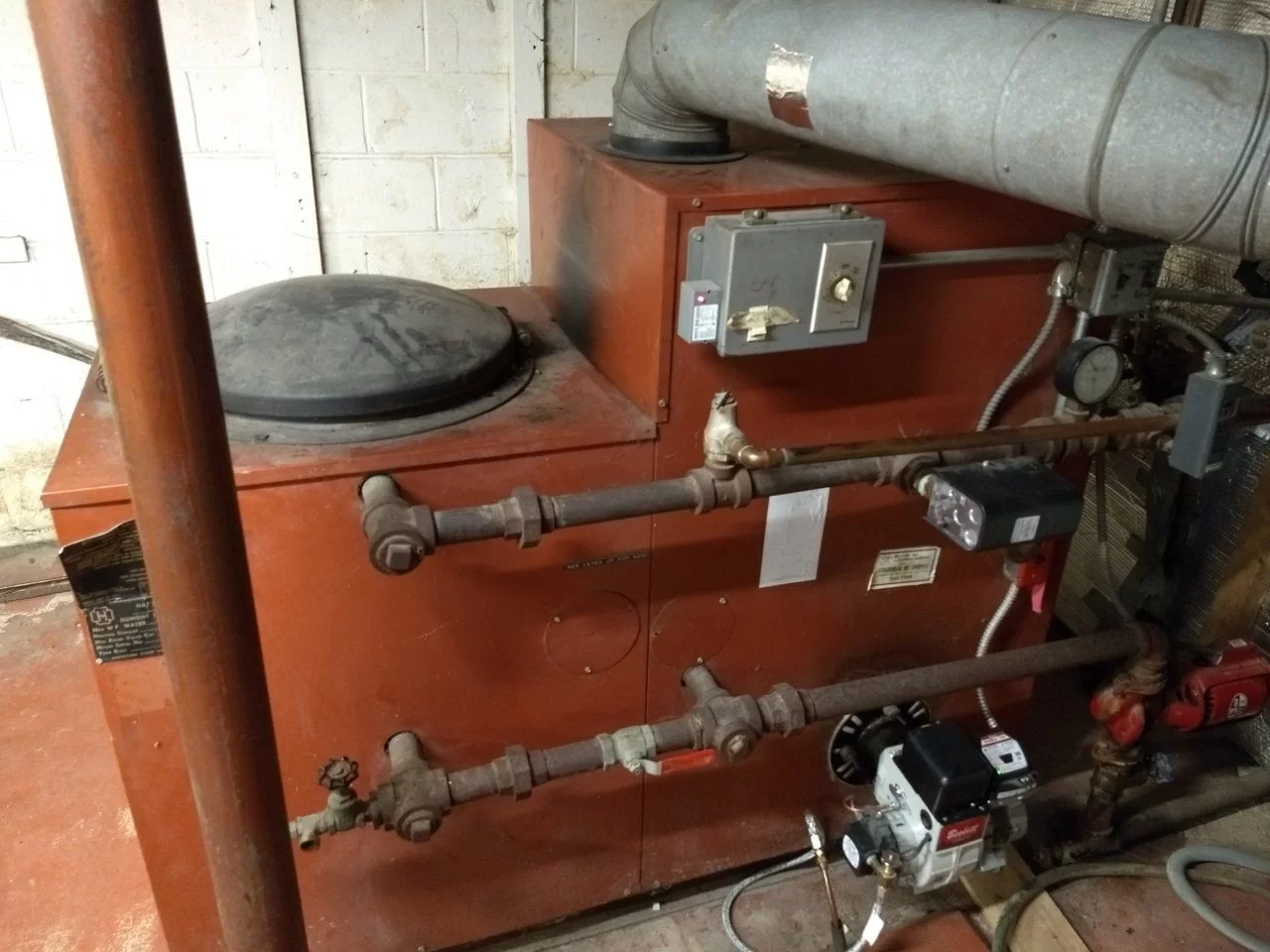

side view 2

Another side view of Dumont Tempest showing most of the exterior "moving" parts.

end view 1

wood combustion chamber in front, 1500 gal water storage tank in background

thermostatic switch

This is the rough-looking wiring to the thermostatic switch that controls the blower and circulator.

Last edited:

![[Hearth.com] Help with Dumont Tempest](/talk/data/attachments/222/222840-c6d30fe3bbfb49c4738a5387632ec245.jpg?hash=1LbnXDCKCr)