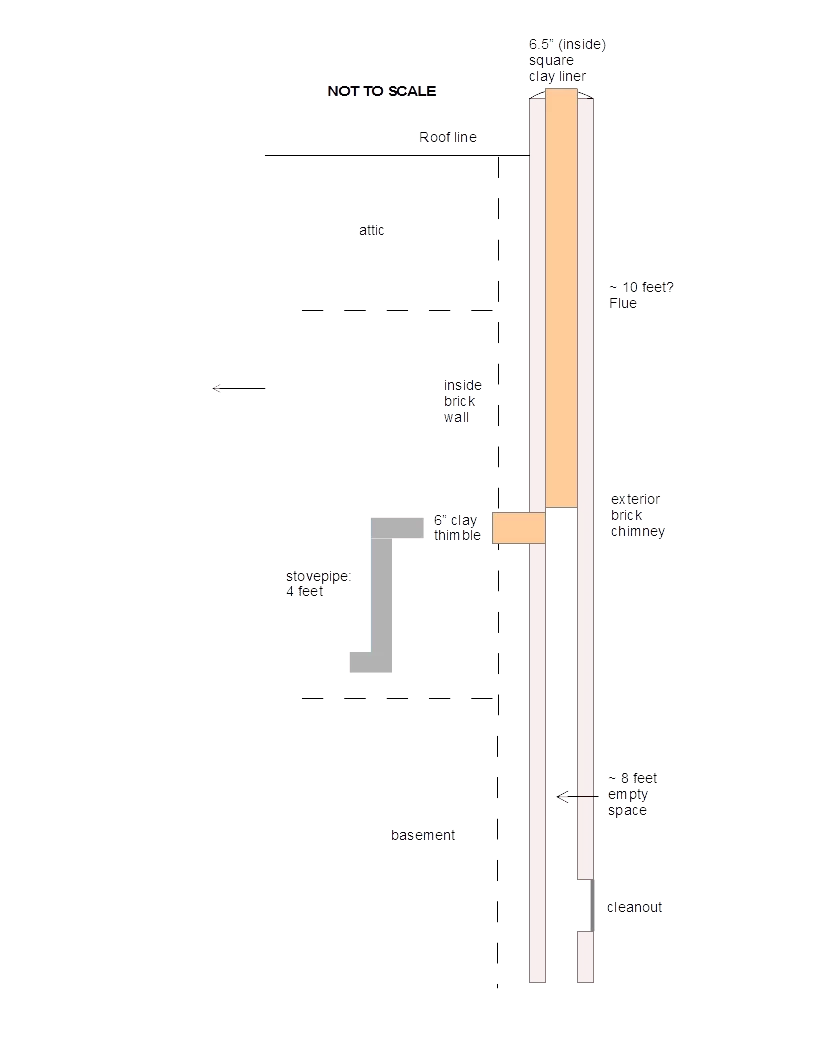

I'm hoping to make a marginal, cheap improvement to my masonry chimney draft. Please see the attached diagram and pics; vertical distances are rough estimates.

This is an exterior chimney with two flues, 6.5" (inside diameter) clay liners, and no caps. I'm using the flue for the upper (main) floor. The flue liner is clean and with no obvious leaks. I have blocked the unused (taller) flue to prevent it from sucking down. I'm using single-wall stovepipe inside.

There is about 8 feet of empty space in the chimney below the stove connection, and the metal cleanout door at the bottom is not perfectly sealed.

Would plugging up the empty chimney space (right below the clay thimble) make much of a difference? What material or device would be safest to use for that?

Would some kind of flue extension help, and if so, how much additional length would actually make a difference?. How about devices such as Vacu-Stack, turbines, wind-directional caps, etc.?

The liner for the flue I'm using is flush with the mortar on top of the chimney, so any cap or other device will have to be inserted into the liner or used with an adapter.

From what I gather, a complete chimney insert kit solves most problems, but I'd like to rule out cheaper solutions before doing that.

This is an exterior chimney with two flues, 6.5" (inside diameter) clay liners, and no caps. I'm using the flue for the upper (main) floor. The flue liner is clean and with no obvious leaks. I have blocked the unused (taller) flue to prevent it from sucking down. I'm using single-wall stovepipe inside.

There is about 8 feet of empty space in the chimney below the stove connection, and the metal cleanout door at the bottom is not perfectly sealed.

Would plugging up the empty chimney space (right below the clay thimble) make much of a difference? What material or device would be safest to use for that?

Would some kind of flue extension help, and if so, how much additional length would actually make a difference?. How about devices such as Vacu-Stack, turbines, wind-directional caps, etc.?

The liner for the flue I'm using is flush with the mortar on top of the chimney, so any cap or other device will have to be inserted into the liner or used with an adapter.

From what I gather, a complete chimney insert kit solves most problems, but I'd like to rule out cheaper solutions before doing that.

![[Hearth.com] Improving my draft](/talk/data/attachments/223/223101-85ac87fd102a0d35ee100dd4e73f8f87.jpg?hash=N6Xpl5-QNE)

Where in TN are you? It's about 2:15 to Nashville from here..

Where in TN are you? It's about 2:15 to Nashville from here..