Howdy,

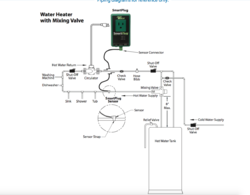

I'm going to be installing my Plate HX for my domestic very soon,but I'm unsure of exactly how to go about installing it the way I want it to work. Currently I have a domestic hot water loop in my house. It's a small circulation pump that circulates my DHW throughout the entire house so I don't have to wait to use hot water.(we really like this feature, especially in the winter).

I would like to use the PHX to preheat my water AND for the DHW loop to circulate through the plate HX to bring the water up to set temp. Thing is I'm not sure how to do this. What components would I need? How do they get plumped?

Another option is to not pre heat the water and run the DHW loop through the plate HX. I think I know how this would work, but how much longer would it take the water to get up to temp. Would I see saving using this method?

Another option I just considered would be to run two plate HX's, one for preheating and one for the loop.

Does anyone have any experience with hooking up DHW with a DHW loop? Any advice on things to look out for when doing the install?

Components that work better than others?

What do you think is the best option for the money?

I'll post a couple diagrams of what I'm thinking from my phone

I'm going to be installing my Plate HX for my domestic very soon,but I'm unsure of exactly how to go about installing it the way I want it to work. Currently I have a domestic hot water loop in my house. It's a small circulation pump that circulates my DHW throughout the entire house so I don't have to wait to use hot water.(we really like this feature, especially in the winter).

I would like to use the PHX to preheat my water AND for the DHW loop to circulate through the plate HX to bring the water up to set temp. Thing is I'm not sure how to do this. What components would I need? How do they get plumped?

Another option is to not pre heat the water and run the DHW loop through the plate HX. I think I know how this would work, but how much longer would it take the water to get up to temp. Would I see saving using this method?

Another option I just considered would be to run two plate HX's, one for preheating and one for the loop.

Does anyone have any experience with hooking up DHW with a DHW loop? Any advice on things to look out for when doing the install?

Components that work better than others?

What do you think is the best option for the money?

I'll post a couple diagrams of what I'm thinking from my phone