Hello,

First off, thanks to the many contributors here. I've been reading on the Hearth forums over the last few months before buying my first stove and have learned lots.

A bit of background...

My house is a 140 year old victorian 2 storey home, with a narrow open pit fireplace and a masonry chimney that goes from the main floor, in the middle of the home, up through the second floor and roof. The chimney stack is probably about 30 feet long. We've burned wood in this 16" wide by 27" high pit for about 4 years since moving in. The last batch of wood I purchased (mostly maple) spent about a year outside seasoning before bringing it into our wood shed last November.

Following the recommendations from an energy efficiency audit last fall, we were going to get a chimney top damper to stop the major source of airleak: the open pit fireplace with a cast iron damper. After further thought, we decided to instead install a wood stove in this opening to reduce the air infiltration and actually provide some heat when we burn wood, rather that cool the house.

Given the narrow width of the firepit, an insert was out of the question. The only local options I was able to find for woodstoves were the Vermont Castings Aspen or the Jotul F602CB. The Aspen would have been a very tight fit so we decided to go with the F602CB.

The installer recommended a 6" stainless steel liner for the install. They also mentioned that I may have an overly strong draft but that I'd have to see how the stove performed. The stove is installed about an inch from the back of the fire pit so that the stove door pretty much flush with the front of the fire pit.

I performed the 3 break in fires as recommended in the manual, using an IR thermometer (using emissivity=0.95) to measure the surface temp at the front top of the stove. It threw in an extra break in fire to 400F for good measure. On the next firing, I used the top down method: two quarter splits on either side, with some smaller kindling across those, with some tinder, topped with four news paper knots.

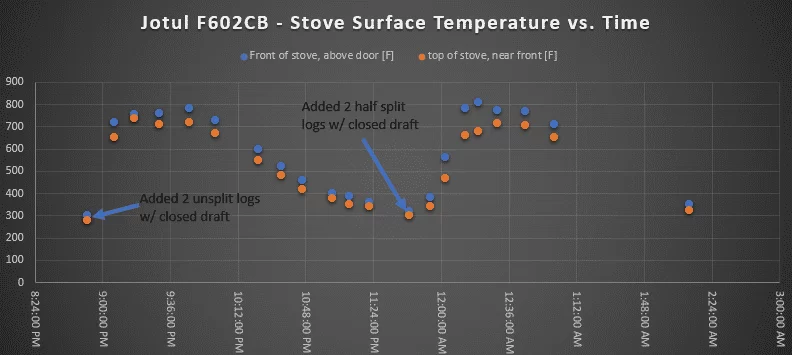

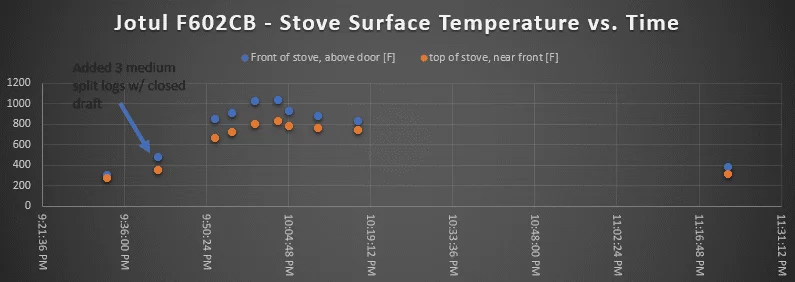

Once the quarter splits on the bottom had caught fire for a few minutes, I added 3 more small half splits to the fire, leaving the draft open for a few minutes and then closed the draft as the fire was running strong (in retrospect, I probably should have checked the surface temp before reloading as I'm guessing the pre-load temp were about 500F) . Even with the draft fully closed, the temperature soared to over 1000F on the front of the stove (measured above the door). I quickly turned on the range hood exhaust and dryer to try to slow down the chimney draft further. Also added a fan to blow air toward the stove. The cooking plate glowed slightly red for about 5 minutes and then the temperature came back down. I've since learned that I have to wait for the surface temperature of the stove to drop to around 300F so that when I reload, I only peak to about 750-800F. Keep in mind, I only ever open the stove draft on the initial cold start. When it comes time to add wood, I just rake the coals towards the front of the stove, add 2 unsplit or large half splits and keep the draft fully closed.

It occurred to me that maybe my wood was very dry. So to verify my wood moisture, I checked a few logs with my moisture meter (inserted pair of nails to the center of log lengthwise, then used those as contacts for my Electrophysics CMT-908 probes) and I'm typically in the 18-25% moisture range so nothing overly dry as far as I can tell.

At this point, I figure I can control against overfiring by very carefully adding large pieces (as large as you can expect to fit in this tiny stove) when the stove temperature drops to 200-300F (measured on front, above door) and making sure to keep the draft to the fully closed position. That being said, what options do I have to make it a bit more resistant to overfiring?

- Reduce the diameter of the liner at the top of the chimney to 5" (suggested by the installer)

- Install a chimney pipe damper, but this wouldn't be straightforward as only the first 2 inches of the pipe is visible. So I'd have to drill a hole through the masonry to be able to toggle the damper on-off. Installation would be tricky as well, I suspect. Plus a pain when it comes time for a chimney sweep.

- ??? or are these behaviors "normal" for the Jotul and I just need to be careful to keep the temps 300F or less between refills and expect 750F-850F front surface peaks with the damper closed?

Also, for those that have the Jotul F602, I often read that the surface temp is taken between the pipe and the cook plate. Since I don't have access to that due to minimal clearance between the top of the stove and the top of the fireplace, what is the typical delta between the temperature there and the temperature taken in front of the cook plate (near the front of the stove)?

Any suggestions welcome!

First off, thanks to the many contributors here. I've been reading on the Hearth forums over the last few months before buying my first stove and have learned lots.

A bit of background...

My house is a 140 year old victorian 2 storey home, with a narrow open pit fireplace and a masonry chimney that goes from the main floor, in the middle of the home, up through the second floor and roof. The chimney stack is probably about 30 feet long. We've burned wood in this 16" wide by 27" high pit for about 4 years since moving in. The last batch of wood I purchased (mostly maple) spent about a year outside seasoning before bringing it into our wood shed last November.

Following the recommendations from an energy efficiency audit last fall, we were going to get a chimney top damper to stop the major source of airleak: the open pit fireplace with a cast iron damper. After further thought, we decided to instead install a wood stove in this opening to reduce the air infiltration and actually provide some heat when we burn wood, rather that cool the house.

Given the narrow width of the firepit, an insert was out of the question. The only local options I was able to find for woodstoves were the Vermont Castings Aspen or the Jotul F602CB. The Aspen would have been a very tight fit so we decided to go with the F602CB.

The installer recommended a 6" stainless steel liner for the install. They also mentioned that I may have an overly strong draft but that I'd have to see how the stove performed. The stove is installed about an inch from the back of the fire pit so that the stove door pretty much flush with the front of the fire pit.

I performed the 3 break in fires as recommended in the manual, using an IR thermometer (using emissivity=0.95) to measure the surface temp at the front top of the stove. It threw in an extra break in fire to 400F for good measure. On the next firing, I used the top down method: two quarter splits on either side, with some smaller kindling across those, with some tinder, topped with four news paper knots.

Once the quarter splits on the bottom had caught fire for a few minutes, I added 3 more small half splits to the fire, leaving the draft open for a few minutes and then closed the draft as the fire was running strong (in retrospect, I probably should have checked the surface temp before reloading as I'm guessing the pre-load temp were about 500F) . Even with the draft fully closed, the temperature soared to over 1000F on the front of the stove (measured above the door). I quickly turned on the range hood exhaust and dryer to try to slow down the chimney draft further. Also added a fan to blow air toward the stove. The cooking plate glowed slightly red for about 5 minutes and then the temperature came back down. I've since learned that I have to wait for the surface temperature of the stove to drop to around 300F so that when I reload, I only peak to about 750-800F. Keep in mind, I only ever open the stove draft on the initial cold start. When it comes time to add wood, I just rake the coals towards the front of the stove, add 2 unsplit or large half splits and keep the draft fully closed.

It occurred to me that maybe my wood was very dry. So to verify my wood moisture, I checked a few logs with my moisture meter (inserted pair of nails to the center of log lengthwise, then used those as contacts for my Electrophysics CMT-908 probes) and I'm typically in the 18-25% moisture range so nothing overly dry as far as I can tell.

At this point, I figure I can control against overfiring by very carefully adding large pieces (as large as you can expect to fit in this tiny stove) when the stove temperature drops to 200-300F (measured on front, above door) and making sure to keep the draft to the fully closed position. That being said, what options do I have to make it a bit more resistant to overfiring?

- Reduce the diameter of the liner at the top of the chimney to 5" (suggested by the installer)

- Install a chimney pipe damper, but this wouldn't be straightforward as only the first 2 inches of the pipe is visible. So I'd have to drill a hole through the masonry to be able to toggle the damper on-off. Installation would be tricky as well, I suspect. Plus a pain when it comes time for a chimney sweep.

- ??? or are these behaviors "normal" for the Jotul and I just need to be careful to keep the temps 300F or less between refills and expect 750F-850F front surface peaks with the damper closed?

Also, for those that have the Jotul F602, I often read that the surface temp is taken between the pipe and the cook plate. Since I don't have access to that due to minimal clearance between the top of the stove and the top of the fireplace, what is the typical delta between the temperature there and the temperature taken in front of the cook plate (near the front of the stove)?

Any suggestions welcome!

Weak draft is definitely not going to be a problem here. This is an interior wall fireplace. No blockoff plate installed. They filled the void around the liner with fibreglass insulation. When they come for my chimney sweep, I will look into getting a blockoff plate installed with a ceramic blanket on top.

Weak draft is definitely not going to be a problem here. This is an interior wall fireplace. No blockoff plate installed. They filled the void around the liner with fibreglass insulation. When they come for my chimney sweep, I will look into getting a blockoff plate installed with a ceramic blanket on top.