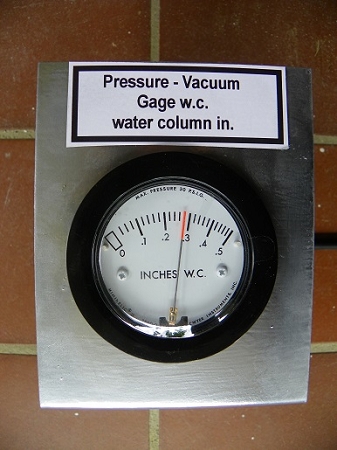

My understanding is that draft is basically measured in WC units as the difference in pressure between your room and the pressure in your exhaust pipe near where it leaves the room. This should be a negative number, as the draft is really a vacuum.

A pellet stove typically has an exhaust fan which is pushing the exhaust out of the stove and into your flue pipe. This is positive pressure.

I've read that the ideal draft is -.05 WC. However, I can't recall if that was for wood stoves or pellet stoves. Is it the same? Different?

Assuming I'm trying to reach -.05 WC, how should I calculate my draft? Is it just the raw pressure reading, or do I take into consideration the positive pressure from the fan?

Example: Exhaust fan creates .035 WC. After the pellet stove has been up and running for 30 min the exhaust pipe is measured at -.055WC.

Is my draft -.055 WC or -.09 WC or something else entirely?

A pellet stove typically has an exhaust fan which is pushing the exhaust out of the stove and into your flue pipe. This is positive pressure.

I've read that the ideal draft is -.05 WC. However, I can't recall if that was for wood stoves or pellet stoves. Is it the same? Different?

Assuming I'm trying to reach -.05 WC, how should I calculate my draft? Is it just the raw pressure reading, or do I take into consideration the positive pressure from the fan?

Example: Exhaust fan creates .035 WC. After the pellet stove has been up and running for 30 min the exhaust pipe is measured at -.055WC.

Is my draft -.055 WC or -.09 WC or something else entirely?